Assembling type building material and preparation method thereof

A building material and assembly technology, applied in the field of building material preparation, can solve the problems of no aldehyde and no glue, etc., and achieve the effect of good waterproof performance, light weight and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

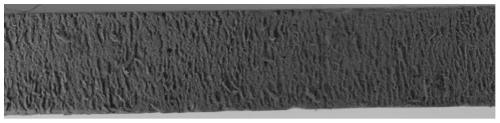

Image

Examples

Embodiment 1

[0052] Embodiment 1: Body of wall brick (size: 240mm * 115mm * 53mm)

[0053] Formula: 50kg of wheat straw, 15kg of sawdust, 10kg of quartz sand, 10kg of 48wt% sodium hydroxide solution, 5kg of urea, 3kg of silica sol (neutral), 1kg of silicone oil.

[0054] Preparation:

[0055] 1) Crushing the wheat straw to debris with a particle size of 0.5-1cm, crushing the sawdust to debris with a particle size of 0.5-1cm, and pulverizing the quartz sand to pass through a 120-mesh sieve;

[0056] 2) Put the pulverized quartz sand and 48wt% sodium hydroxide solution into the reaction kettle, pressurize the steam to 1MPa and react for 34-50 hours, and the filtrate is 60 degrees Baume (°Bé).

[0057] 3) Add urea to the filtrate (together with unreacted quartz sand) to fully dissolve the urea, then add wheat straw and sawdust mixed debris and stir well (speed 600-1000r / min, stirring time 5-10min ), control the reaction temperature below 40°C, so as not to cause agglomeration, which is not ...

Embodiment 2

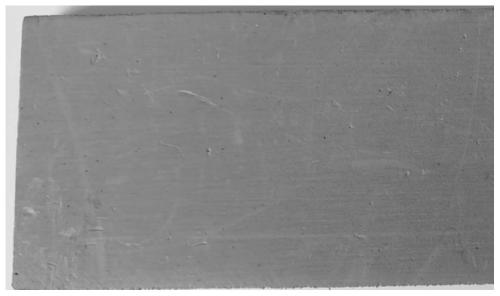

[0066] Embodiment 2: Interior decoration material (floor: 910mm×120mm×18mm)

[0067] Formula: 60kg of corn stalks, 10kg of quartz sand, 10kg of 48wt% sodium hydroxide solution, 5kg of urea, 2.5kg of silica sol (neutral), and 1.5kg of silicone oil.

[0068] Preparation:

[0069] 1) crushing corn stalks to 120 mesh, crushing and refining quartz sand to pass through a 120 mesh sieve;

[0070] 2) First add quartz sand and 48wt% sodium hydroxide solution into the reaction kettle, pressurize the steam to 1 MPa and react for 34 hours to 50 hours, and the filtrate is 60 degrees Baume (°Bé).

[0071] 2) Add urea to the filtrate (together with unreacted quartz sand) to fully dissolve the urea, then add corn stalk debris and stir well (rotational speed 600-1000r / min, stirring time 5-10min), control the reaction temperature Below 40°C to avoid agglomeration, which is not conducive to molding;

[0072] 3) Put the material in step 2) into the mold, and heat press (temperature 50-60° C.) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com