Raw material mixing device for constructional engineering

A construction engineering and mixing device technology, applied in mixers, mixers with rotary mixing devices, transportation and packaging, etc., can solve problems such as poor mixing efficiency, and achieve high mixing efficiency, low processing costs, and good effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

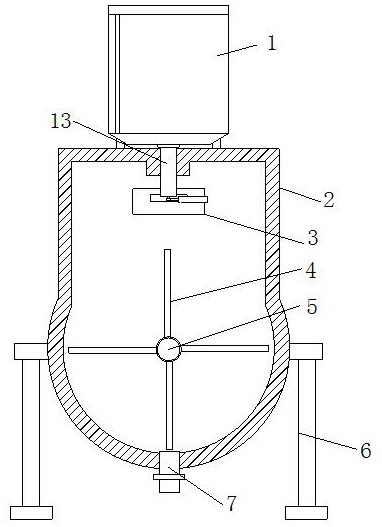

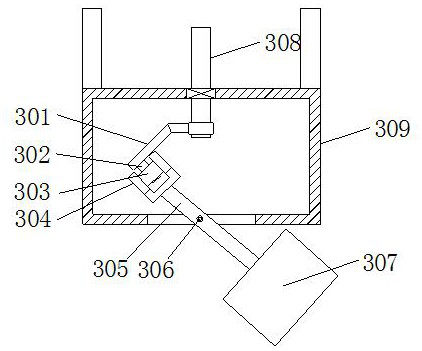

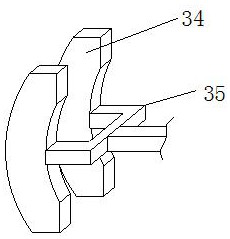

[0021] Embodiment: Put the raw materials that need to be mixed into the raw material storage box 1 for storage. When mixing is required, first start the biaxial motor 9 and the reducer 12, and the biaxial motor 9 will drive the power shaft 308 to rotate after being decelerated by the reducer 12 , the rotating power shaft 308 drives the connecting arm 301 to rotate, and then drives the connecting rod 302 to rotate, the rotating connecting rod 302 drives the connecting block 303 to move, the connecting block 303 moves up and down on the inner side wall of the connecting clamp block 304, and drives the connecting clamp block 304 reciprocates left and right, and the connecting clamp 304 that reciprocates left and right drives the blocking plate 307 to swing back and forth through the connecting plate 305. At this time, the connecting plate 305 reciprocates through the pin shaft 306 and the inner side wall of the square channel. When the blocking plate 307 swings When it reaches the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com