A method for predicting the minimum mixing time of ladle

A prediction method and time prediction technology, applied in the field of metallurgy, can solve problems such as insufficient comprehensive factors and insufficient mathematical formula connection, and achieve the effect of reasonable mathematical model, simple calculation, and reduction of repetitive work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0082] Research on cold state model of 100t ladle in a steel plant. Relevant data can be found in the article "Water Simulation Research on Mixing Time in 100t Ladle", Metallurgical Series, 2010, 02, 003.

[0083] (1) Basic information:

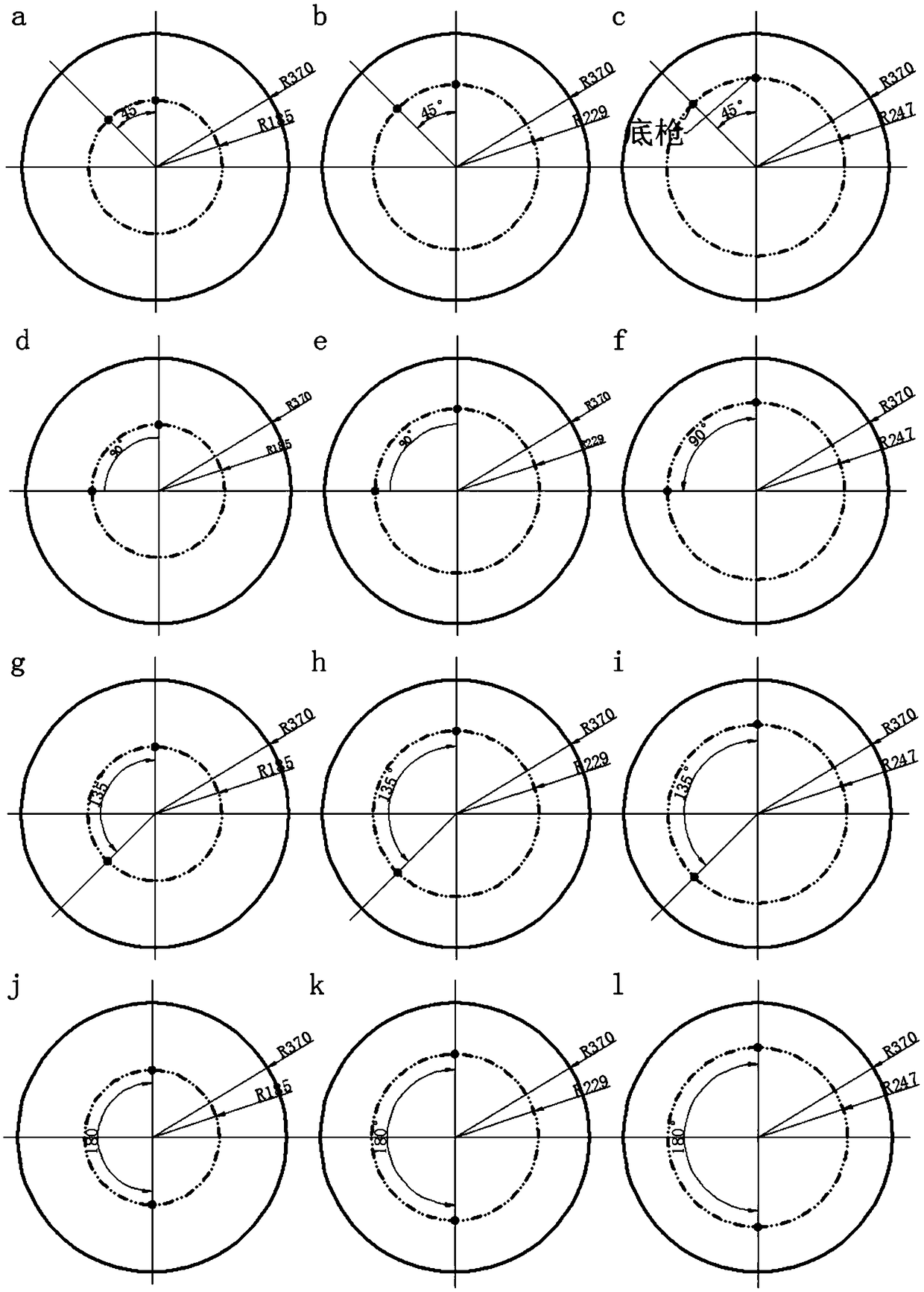

[0084] see figure 1 , 100t bottom-blown argon ladle, according to the ratio of 3.5:1 reduction for cold model research. The best bottom blowing model and injection parameters need to be obtained through experimental research. The prototype and model parameters are shown in Table 1 to Table 2. The bottom blowing arrangement used in the model is as follows figure 1 shown. The results obtained for different schemes are shown in Table 3.

[0085] Table 1 Physical parameters of ladle and model

[0086]

[0087] Table 2 Bottom blowing parameters of ladle and model

[0088]

[0089] Table 3 Minimum mixing time of different schemes

[0090]

[0091] (2) Application method

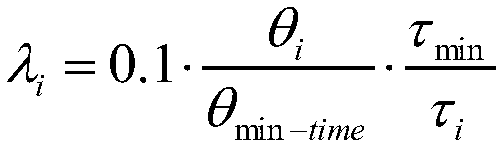

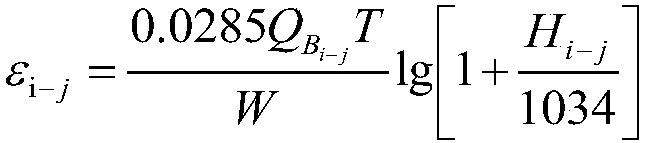

[0092] Calculate according to the embodiment of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com