Silver ion antibacterial fabric and application thereof

An antibacterial fabric and silver ion technology, applied in the field of antibacterial fabrics, can solve the problems of fiber products losing antibacterial ability, blocking the feeding port and discharging port, reducing stirring efficiency, etc. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Silver ion antibacterial fabric, the preparation method of this silver ion antibacterial fabric comprises the steps:

[0052] S1. Weigh the following raw materials in parts by weight: 50 parts of polyacrylonitrile, 100 parts of solvent and 130 parts of water;

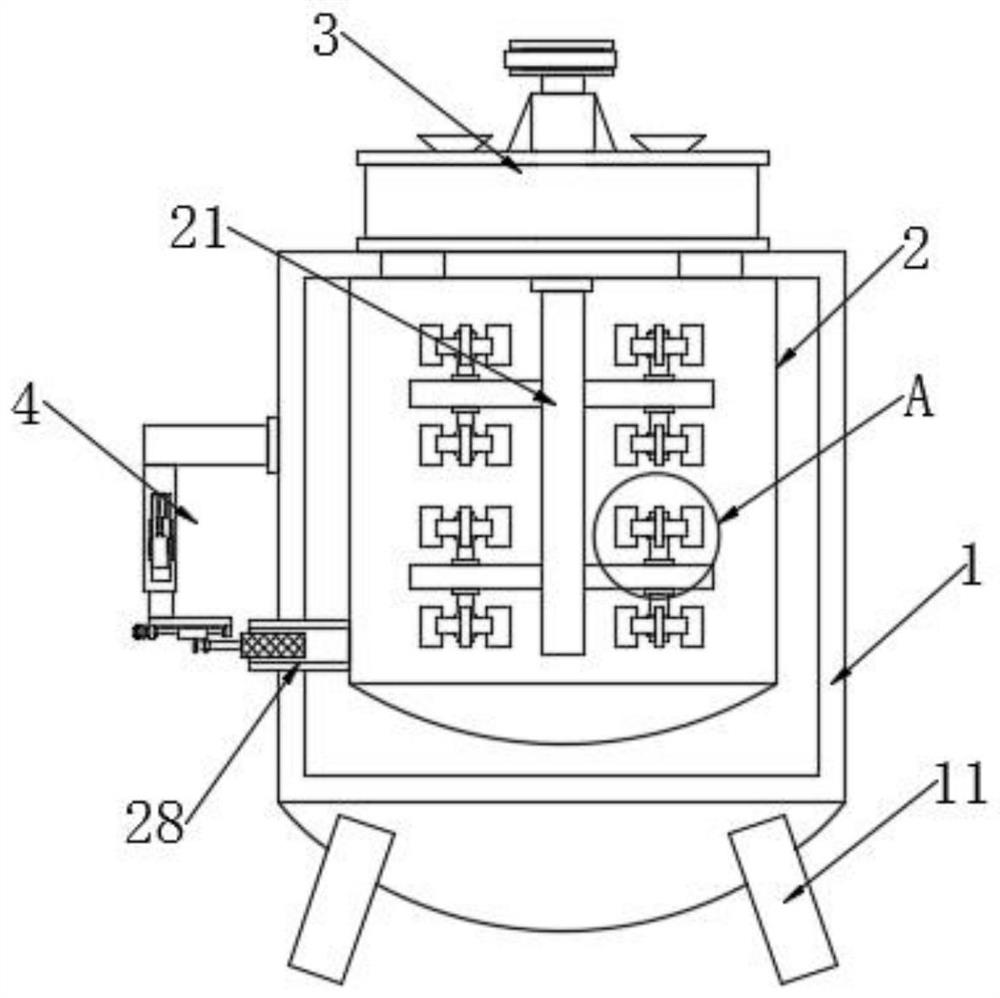

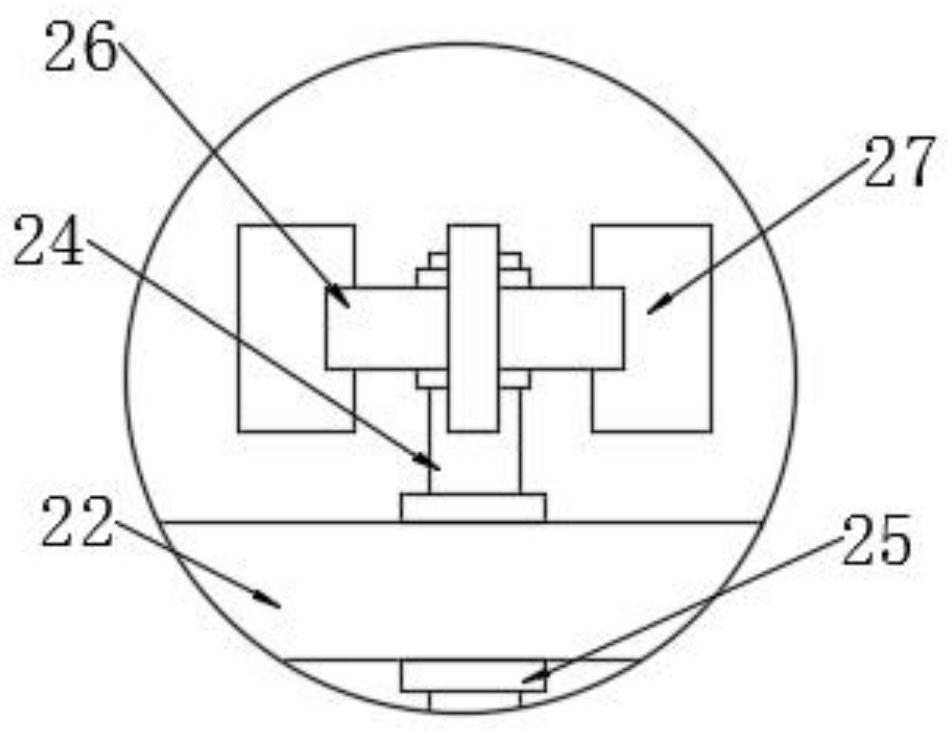

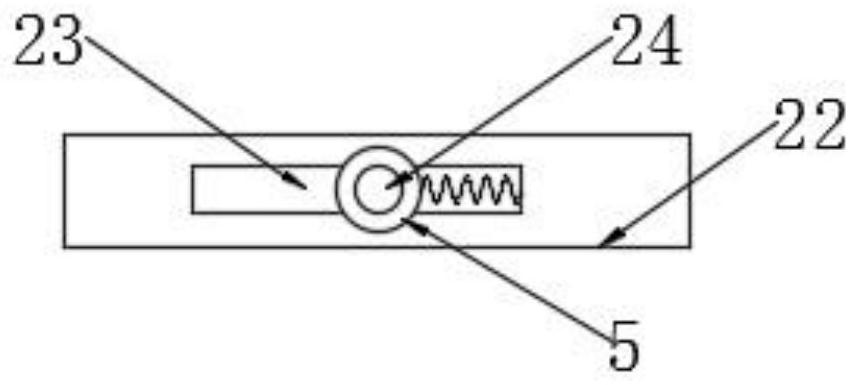

[0053] S2. Put polyacrylonitrile and solvent as raw materials into a mixing and stirring device, and stir for 2 hours at a temperature of 80° C. to obtain a mixture;

[0054] S3, after the silver is purified by electrolysis, it is placed in water for micro-electrolysis to release anions to obtain a colorless and transparent silver ion aqueous solution;

[0055] S4. Put the mixture into the silver ion aqueous solution, adjust the stirring speed, and stir until the color of the solution turns light yellow, then carry out a vacuum treatment process on the stock solution to obtain the fiber stock solution;

[0056] S5. The raw fiber solution is obtained by the emulsion spinning method to obtain the primary fiber, an...

Embodiment 2

[0060] Silver ion antibacterial fabric, the preparation method of this silver ion antibacterial fabric comprises the steps:

[0061] S1. Weigh the following raw materials in parts by weight: 55 parts of polyacrylonitrile, 110 parts of solvent and 140 parts of water;

[0062] S2. Put polyacrylonitrile and solvent as raw materials into a mixing and stirring device, and stir for 2.5 hours at a temperature of 80-90° C. to obtain a mixture;

[0063] S3, after the silver is purified by electrolysis, it is placed in water for micro-electrolysis to release anions to obtain a colorless and transparent silver ion aqueous solution;

[0064] S4. Put the mixture into the silver ion aqueous solution, adjust the stirring speed, and stir until the color of the solution turns light yellow, then carry out a vacuum treatment process on the stock solution to obtain the fiber stock solution;

[0065] S5. The raw fiber solution is obtained by the emulsion spinning method to obtain the primary fibe...

Embodiment 3

[0069] Silver ion antibacterial fabric, the preparation method of this silver ion antibacterial fabric comprises the steps:

[0070] S1. Weigh the following raw materials in parts by weight: 60 parts of polyacrylonitrile, 120 parts of solvent and 150 parts of water;

[0071] S2. Put polyacrylonitrile and solvent as raw materials into a mixing and stirring device, and stir for 3 hours at a temperature of 90° C. to obtain a mixture;

[0072] S3, after the silver is purified by electrolysis, it is placed in water for micro-electrolysis to release anions to obtain a colorless and transparent silver ion aqueous solution;

[0073] S4. Put the mixture into the silver ion aqueous solution, adjust the stirring speed, and stir until the color of the solution turns light yellow, then carry out a vacuum treatment process on the stock solution to obtain the fiber stock solution;

[0074] S5. The raw fiber solution is obtained by the emulsion spinning method to obtain the primary fiber, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com