Efficient grinding fluid stirrer

A technology of grinding liquid and agitator, which is applied in the direction of mixer accessories, springs/shock absorbers, chemical instruments and methods, etc. It can solve the problems of affecting the use effect of grinding liquid, low efficiency of grinding liquid mixing, and difficulty in stirring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

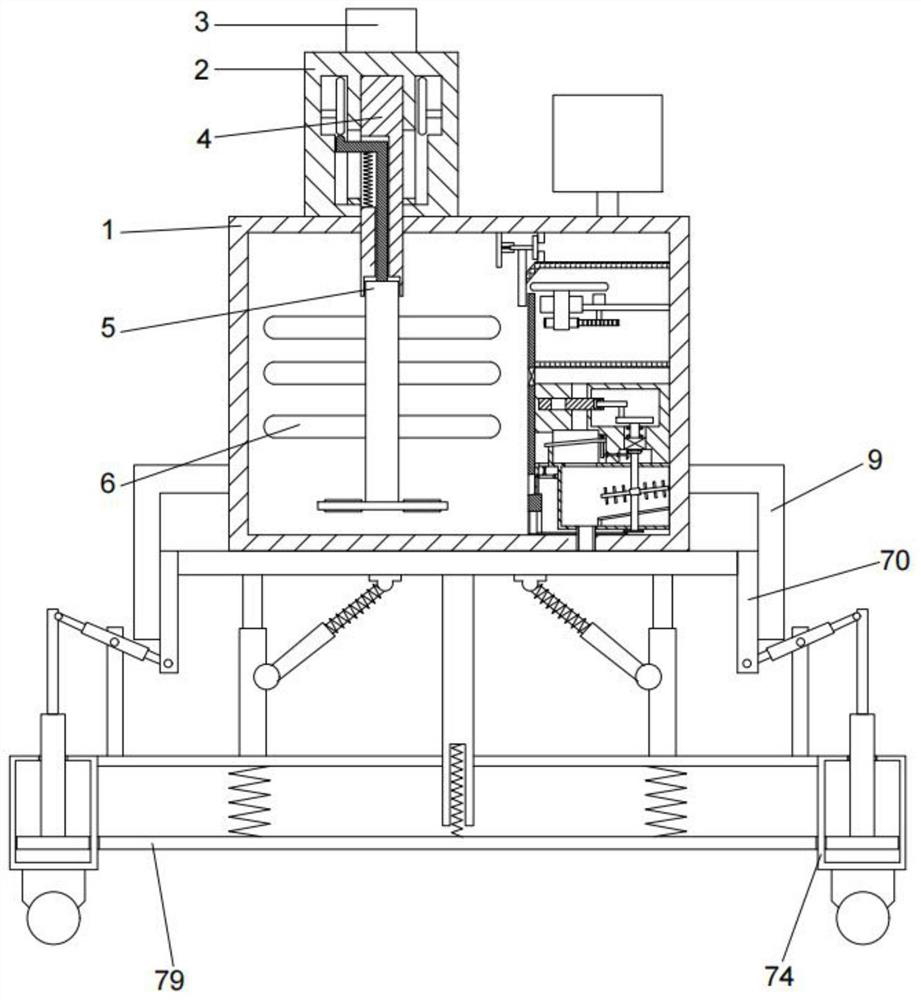

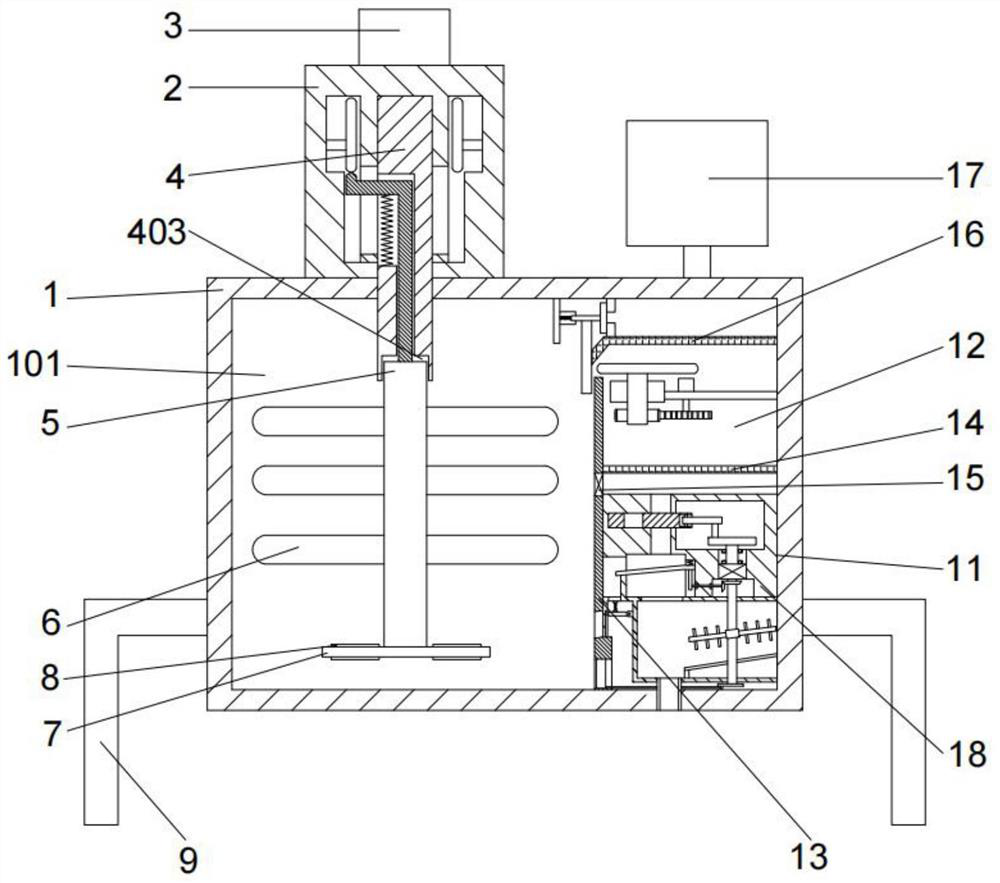

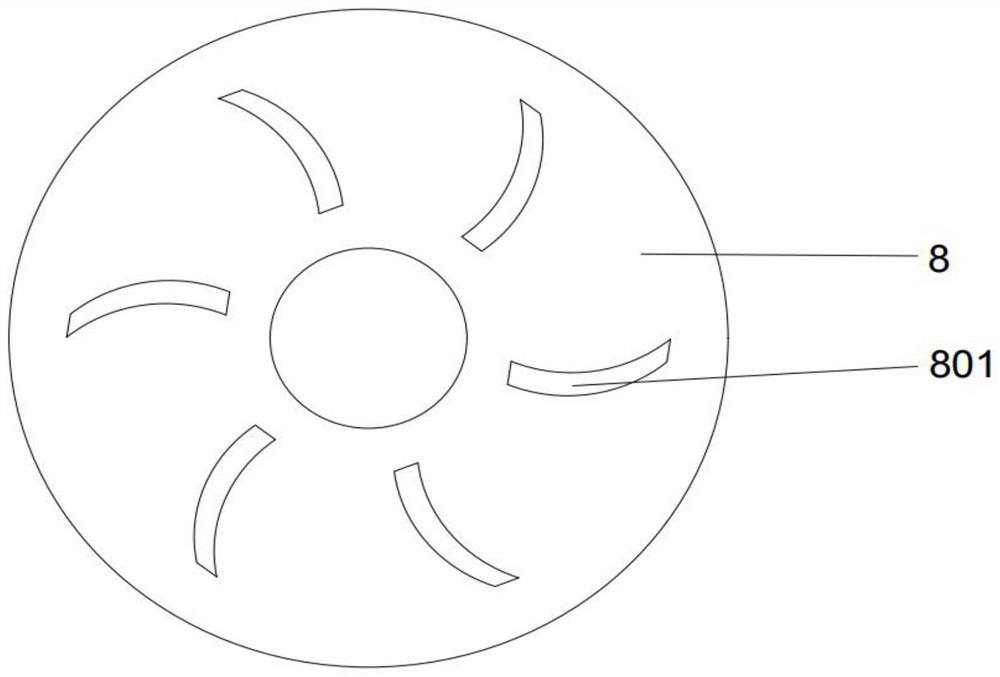

[0056] Embodiments of the present invention provide a high-efficiency grinding liquid agitator, such as Figure 1-3 As shown, it includes a shell 1 and a power shell 2, the upper end of the shell 1 is fixedly provided with the power shell 2, the side end of the shell 1 is evenly distributed with a number of brackets 9 in the circumferential direction, and the shell 1 is connected by a partition 13. Divided into a stirring chamber 101 and a processing chamber, the processing chamber is divided into a feeding chamber 12 and a filtering chamber 11 from top to bottom by a partition 2 14, and the stirring chamber 101 communicates with the feeding chamber 12 and the filtering chamber 11 respectively, The inside of the filter cavity 11 is provided with a filter assembly, the filter assembly includes a filter bin 1803 and a filter residue bin 1805, the power shell 2 is rotationally connected with the rotation shaft 1 4, and the power shell 2 is provided for driving the The rotating sh...

Embodiment 2

[0061] On the basis of above-mentioned embodiment 1, as Figure 1-5 As shown, the upper end of the power shell 2 is fixed with the motor one 3, and an adjustment device is also connected between the rotation shaft one 4 and the stirring rod 5, and the adjustment device includes: the rotation shaft one 4 The opening slot 401 provided on the left side of the upper part, the middle part of the rotating shaft one 4 is provided with the movable chamber two 402, the bottom of the rotating shaft one 4 is provided with the installation groove 403, the opening groove 401, the movable chamber two 402 and The installation groove 403 is sequentially connected up and down;

[0062] The upper end of the power housing 2 is fixed with a motor 3, and the upper side of the power housing 2 is provided with a mounting hole 201, and the mounting hole 201 is rotatably connected with the rotating shaft 4, and the rotating shaft 4 The upper end of the power shell 2 is fixedly connected with the moto...

Embodiment 3

[0067] On the basis of Example 1, such as Figure 6 As shown, the feeding chamber 12 communicates with the feeding bin 17 through the feeding port 1701 passing through the housing 1, and a feeding assembly is provided inside the feeding chamber 12, and the feeding assembly includes:

[0068] Support plate one 16, the support plate one 16 and the upper end of the housing 1 form a liquid storage chamber 1201, the upper and lower ends of the left side of the liquid storage chamber 1201 are symmetrically provided with stoppers 36, and between the stoppers 36 There is a through hole 3601, the left side of the through hole 3601 is provided with a baffle 35, the baffle 35 is fixedly connected with the connecting rod 31, and the lower end of the connecting rod 31 is fixedly provided with a baffle 2 30, the The first connecting rod 31 is fixedly connected with the second spring 33, the second spring 33 is fixedly arranged inside the sleeve 32, the first connecting rod 31 is slidably co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com