Heat exchange and flow guide structure of hot water storage tank

A technology for heat storage tanks and heat exchange tanks, which is applied to heat storage equipment, heat exchange equipment, heat exchanger types, etc., and can solve problems such as reduced water volume, mixed water in the heat storage tank, and failure to meet the required operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

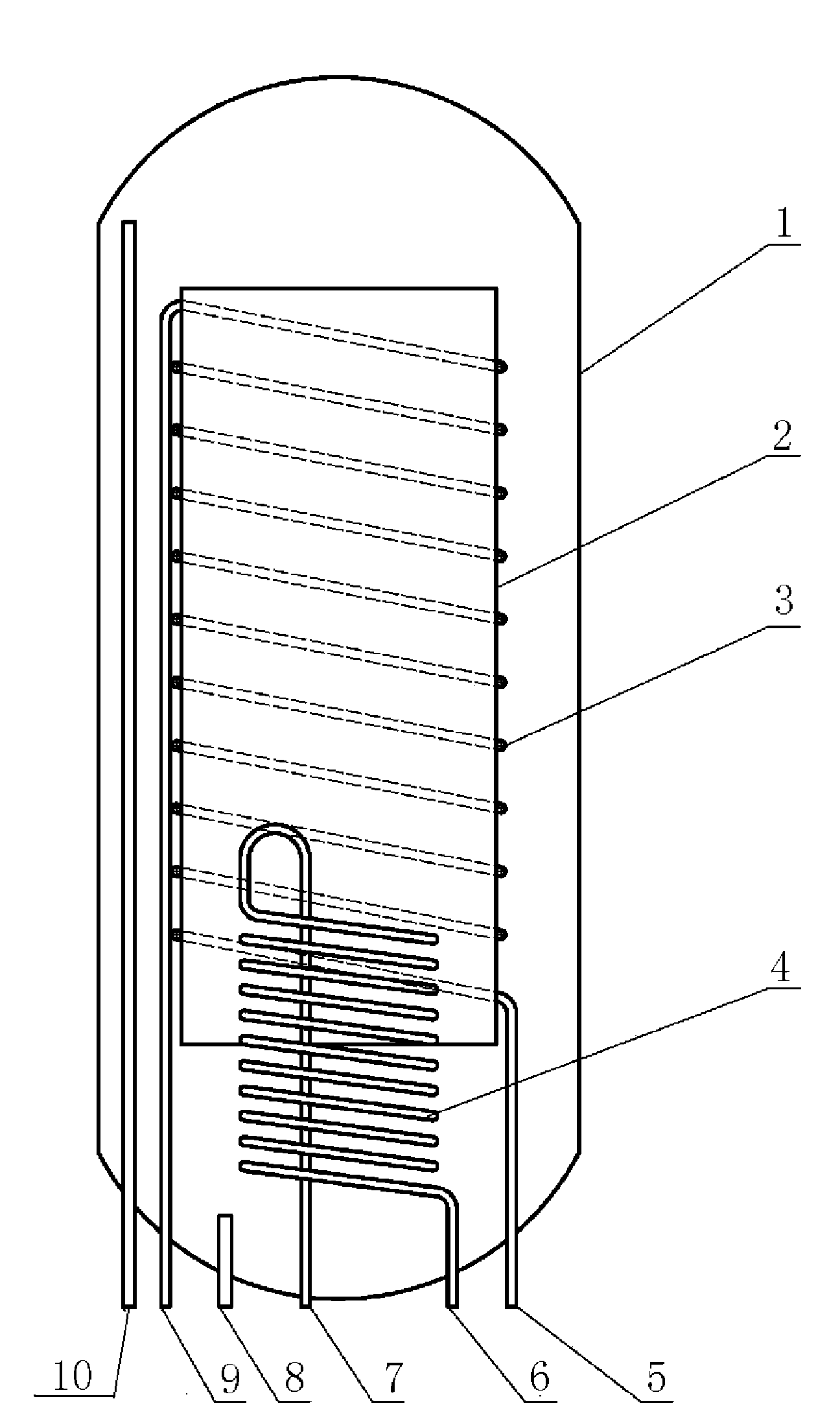

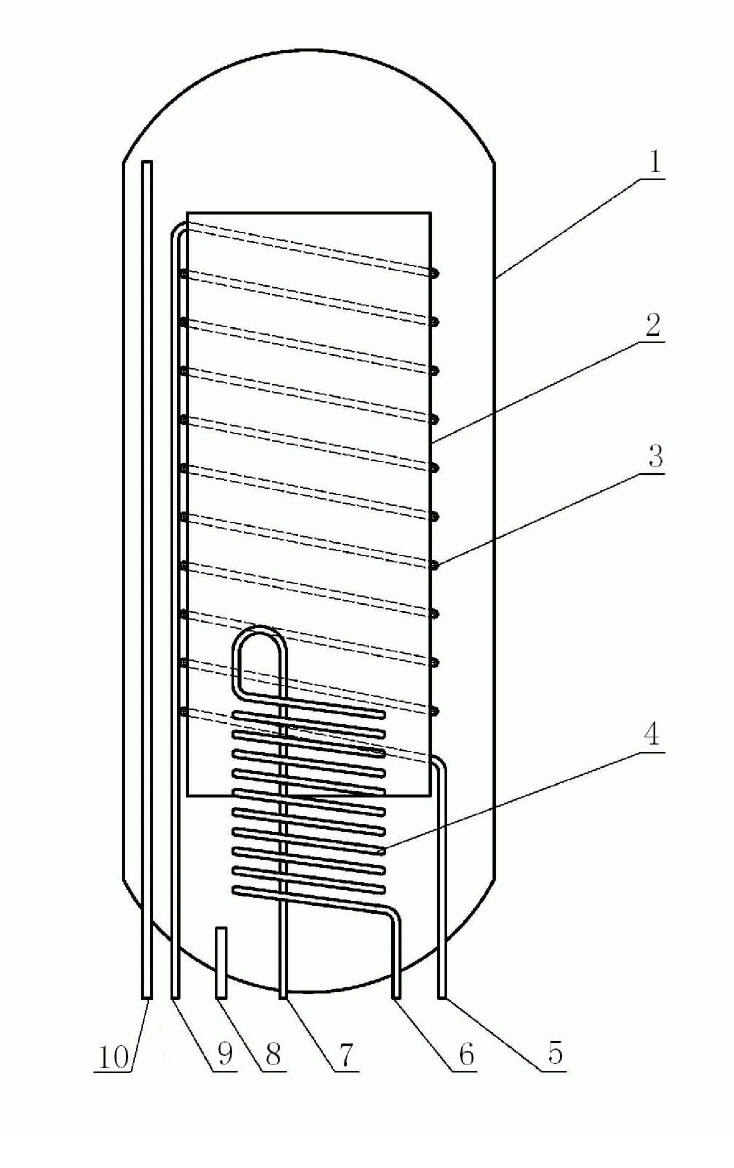

[0013] Embodiment 1 of the present invention will refer to the appended figure 1 To describe, 8 tank inlets and 5 heat inlets are connected to tap water pipelines, 6 heat source outlets and 7 heat source inlets are respectively connected to the cold end and hot end of the heat source, and 9 heat extraction outlets are connected to the hot water end.

[0014] Fill tank 1 with water through the inlet of tank 8 until the outlet of tank 10 leaves water. The heat source medium enters the 4 heat source heat exchanger through the 7 heat source inlet to exchange heat with the water in the tank, and flows out through the 6 heat source outlet, and the temperature of the heat storage medium water in the tank increases. The cold water enters the 3 heat exchanger through the 5 heat extraction inlet and exchanges heat with the heat storage medium and flows out through the 9 heat extraction outlet to be used. The heat storage medium in the guide tube moves upward, and the heat storage mediu...

Embodiment 2

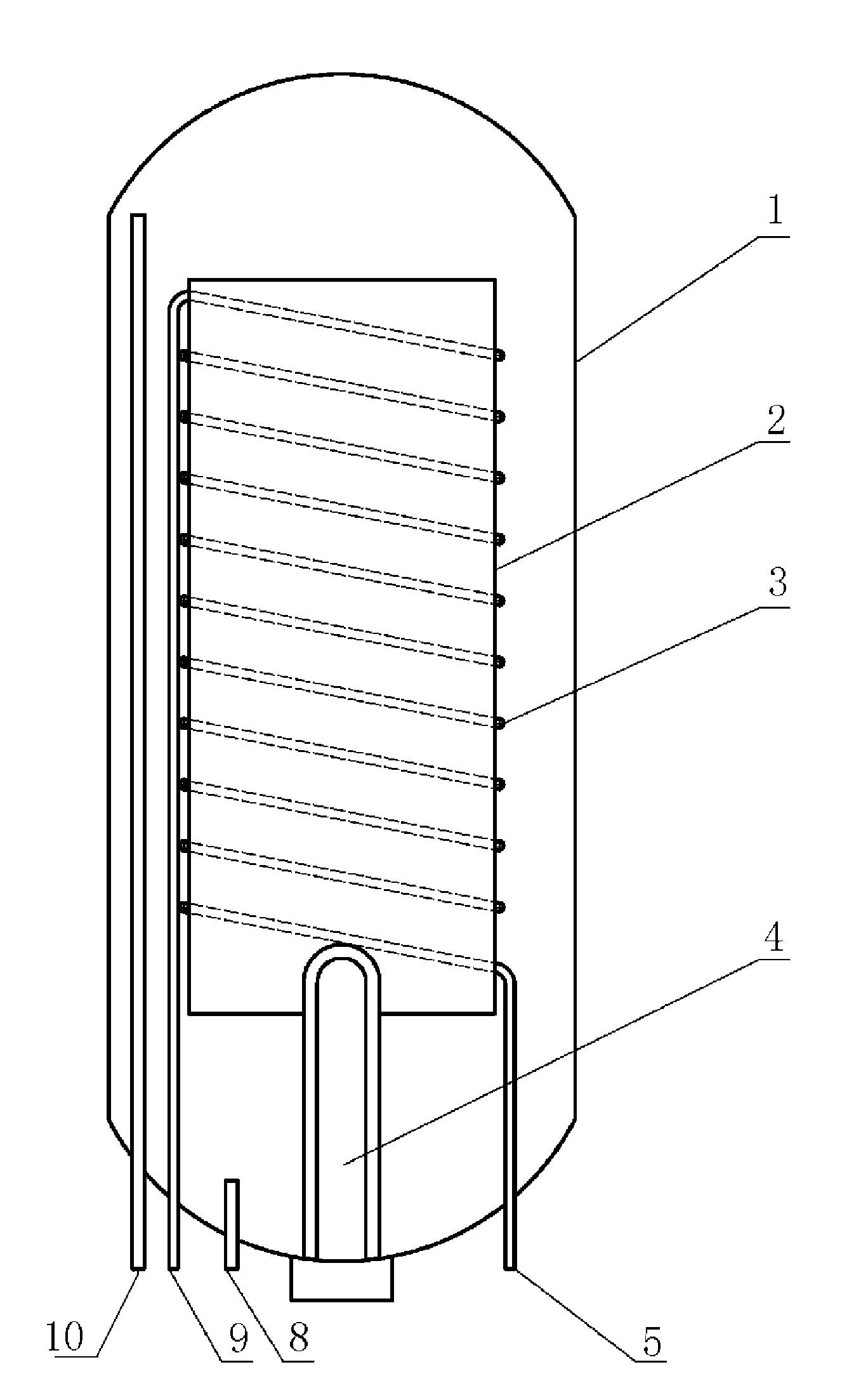

[0016] An embodiment of the present invention that uses different heating methods for the heat source heat exchanger described in the heat exchange and flow guide structure of the hot water storage tank. This example adopts the electric heating method.

[0017] Embodiment 2 of the present invention will refer to the appended figure 2 For description, 8 tank inlets and 5 heat inlets are connected to the tap water pipeline, and 9 heat outlets are connected to the hot water end.

[0018] Fill tank 1 with water through the inlet of tank 8 until the outlet of tank 10 leaves water. Turn on the power switch of the electric heater, and the temperature of the heat storage medium water in the tank increases. The cold water enters the 3 heat exchanger through the 5 heat extraction inlet and exchanges heat with the heat storage medium and flows out through the 9 heat extraction outlet to be used. The heat storage medium in the guide tube moves upward, and the heat storage medium in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com