Fractal bubble configuration controllable type slurry bed reactor

A reactor, controllable technology, applied in chemical instruments and methods, hydrocarbon oil cracking, hydrocarbon oil treatment, etc., can solve the problems of insufficient mixing intensity of the flow field in the reactor and inaccurate control of the bubble size. The effect of heat extraction and mass transfer, strong liquid turbulence, and uniform gas-liquid flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

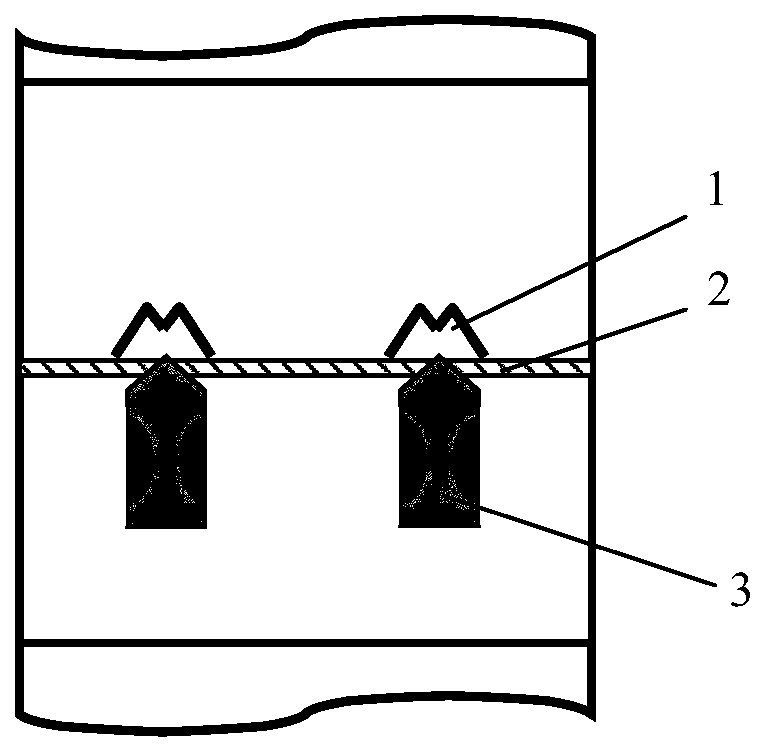

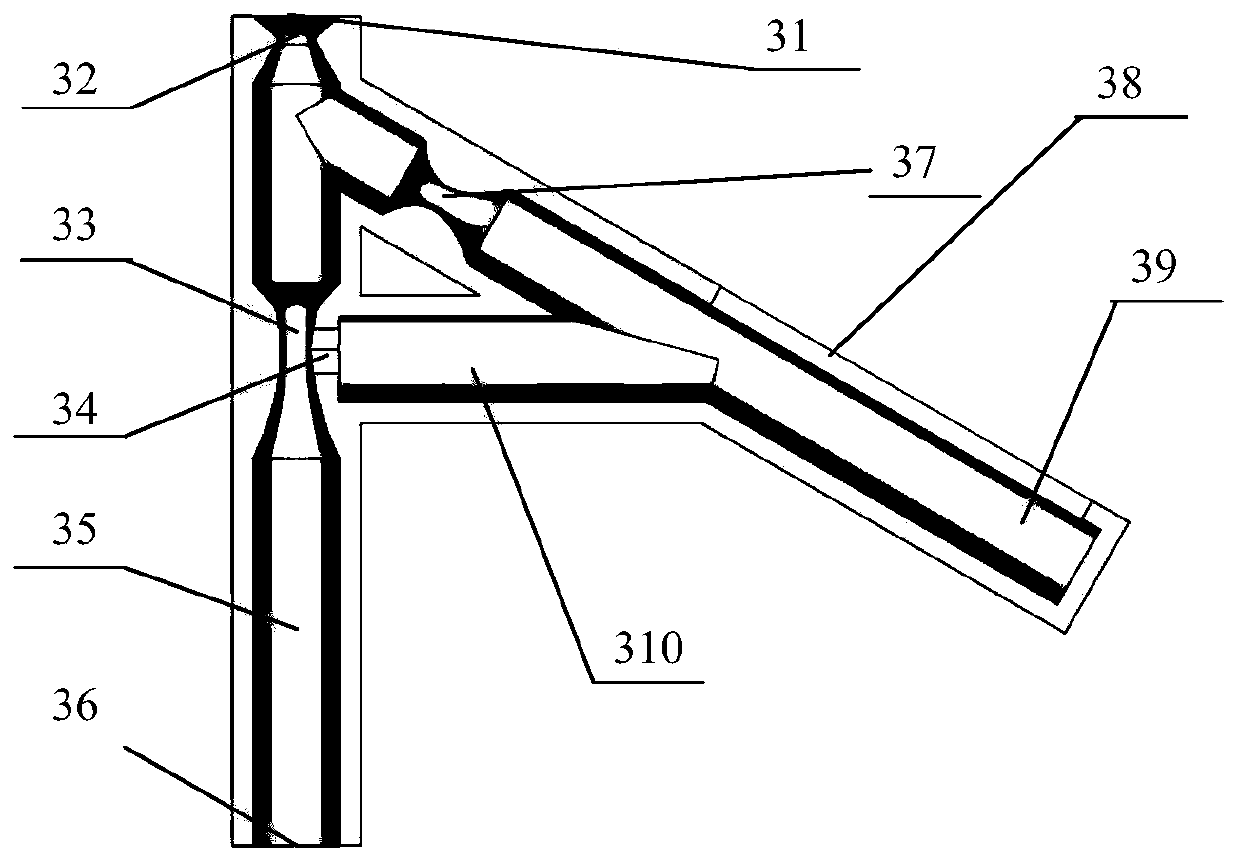

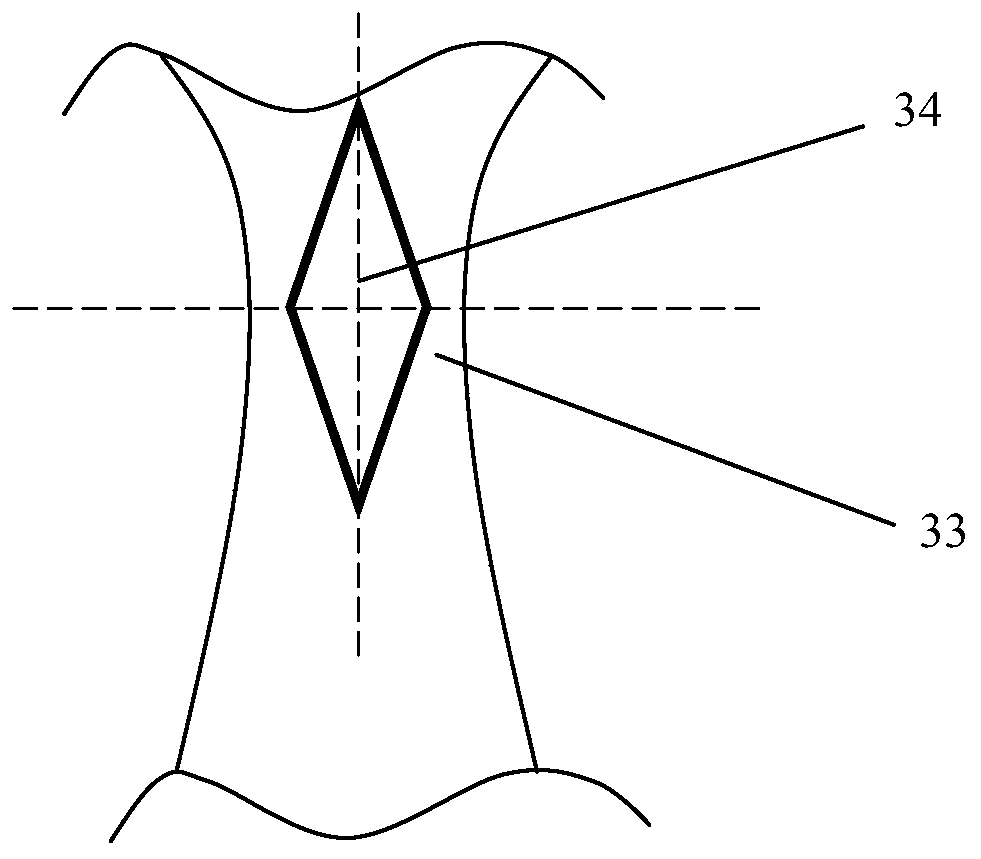

[0028] At present, there are two main forms of slurry-bed gas distributors at home and abroad. One is that the gas phase enters the slurry-bed reactor through throttling bubbling; the other is that the gas phase enters the slurry-bed reactor after the liquid is sheared and broken. When the gas phase enters the slurry-bed reactor through the liquid shearing nozzle, the bubble size is difficult to control when the gas-liquid flow fluctuates or the process is adjusted, and the problems of flying temperature, coking, and product quality degradation are extremely easy to occur. However, the size of the bubbles generated by bubbling alone is too large to meet the increasingly refined reactor operating conditions. Using the A-type strong mixing method, both smaller bubbles and larger bubbles are produced, and the ratio of the two bubbles produced by this method is only related to the liquid phase flow rate, that is, under the same liquid phase feed, change into the reactor The gas rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com