A kind of preparation technology of nano tin powder

A preparation process, nano-tin powder technology, applied in nanotechnology and other directions, can solve the problems of high temperature and pressure, difficult to meet the needs of special use occasions, not energy saving and environmental protection, and achieve uniform distribution, low equipment cost, and controllable scale. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The gallium-based liquid alloy is selected to prepare tin-containing liquid alloy, and the mass percentages of each component are gallium: 60%, purity 99.9%; indium: 25%, purity 99.9%; tin: 15%, purity 99.9%. Choose the vacuum induction melting process, put the ingredients into the melting crucible according to the above ratio, close the hatch, turn on the vacuum pump, when the vacuum degree reaches 5*10 -3 Melting is carried out after Pa is above; the melting temperature is 1000°C, and after holding for 1 minute, turn off the melting switch, wait for the melt to cool down to around room temperature, open the furnace door, take out the crucible, and obtain a tin-containing liquid alloy.

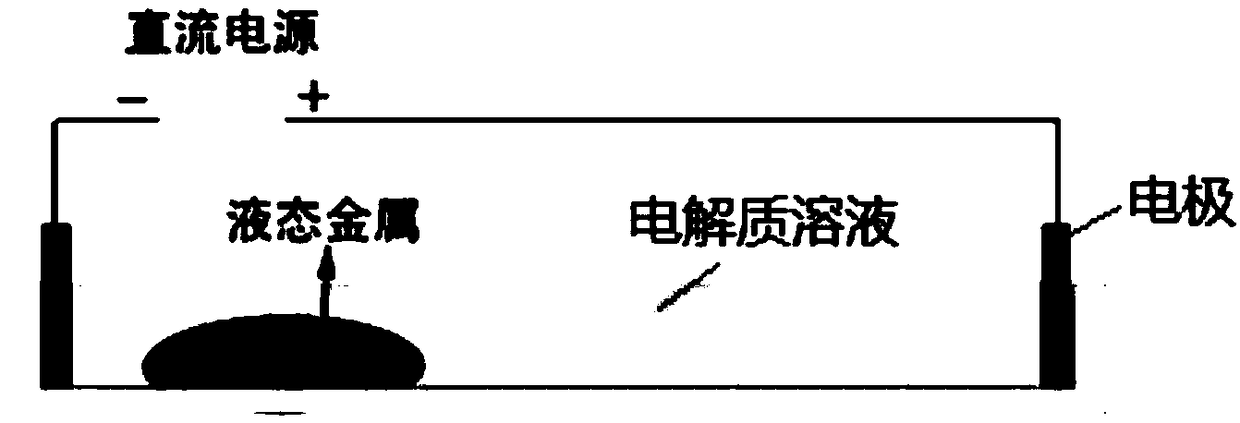

[0048] Such as figure 1As shown, set up the experimental equipment. Use a dropper to draw an appropriate amount of 0.3 mol / L NaOH solution into the water tank, adjust the pH to 12.5-14.5, take out 10 ml of the above prepared tin-containing liquid alloy from the crucible, and drop it i...

Embodiment 2

[0050] The gallium-based liquid alloy is selected to prepare tin-containing liquid alloy, and the mass percentages of each component are gallium: 60%, purity 99.9%; indium: 25%, purity 99.9%; tin: 15%, purity 99.9%. Choose the vacuum induction melting process, put the ingredients into the melting crucible according to the above ratio, close the hatch, turn on the vacuum pump, when the vacuum degree reaches 5*10 -3 Melting is carried out after Pa is above; the melting temperature is 1000°C, and after holding for 1 minute, turn off the melting switch, wait for the melt to cool down to around room temperature, open the furnace door, take out the crucible, and obtain a tin-containing liquid alloy.

[0051] Such as figure 1 As shown, set up the experimental equipment. Use a dropper to draw an appropriate amount of 0.5 mol / L NaOH solution into the water tank, adjust the pH to 12.5-14.5, take out 10 ml of the liquid alloy containing tin prepared above from the crucible, and drop it ...

Embodiment 3

[0053] The gallium-based liquid alloy is selected to prepare tin-containing liquid alloy, and the mass percentages of each component are gallium: 60%, purity 99.9%; indium: 25%, purity 99.9%; tin: 15%, purity 99.9%. Choose the vacuum induction melting process, put the ingredients into the melting crucible according to the above ratio, close the hatch, turn on the vacuum pump, when the vacuum degree reaches 5*10 -3 Melting is carried out after Pa is above; the melting temperature is 1000°C, and after holding for 1 minute, turn off the melting switch, wait for the melt to cool down to around room temperature, open the furnace door, take out the crucible, and obtain a tin-containing liquid alloy.

[0054] Such as figure 1 As shown, set up the experimental equipment. Use a dropper to draw an appropriate amount of 0.7 mol / L NaOH solution into the water tank, adjust the pH to 12.5-14.5, take out 10 ml of the liquid alloy containing tin prepared above from the crucible, and drop it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com