High order polythiophene film and preparation process thereof

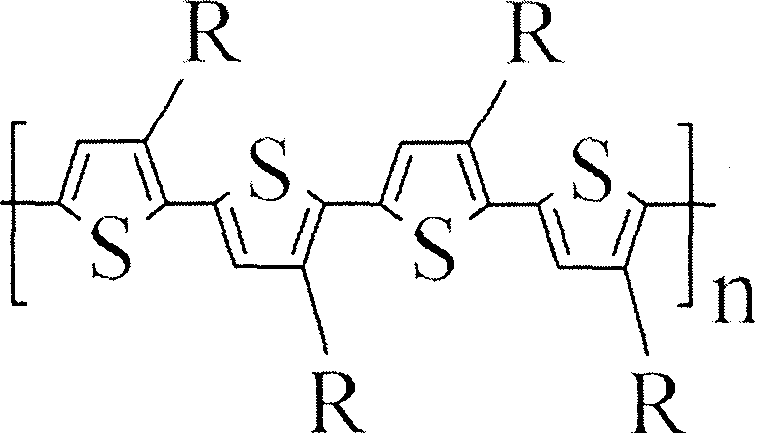

A technology of polythiophene and thin film, which is applied in the field of highly ordered polythiophene thin film and its preparation, can solve the problems of reducing carrier mobility and achieve the effect of improving carrier mobility and crystallization order

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

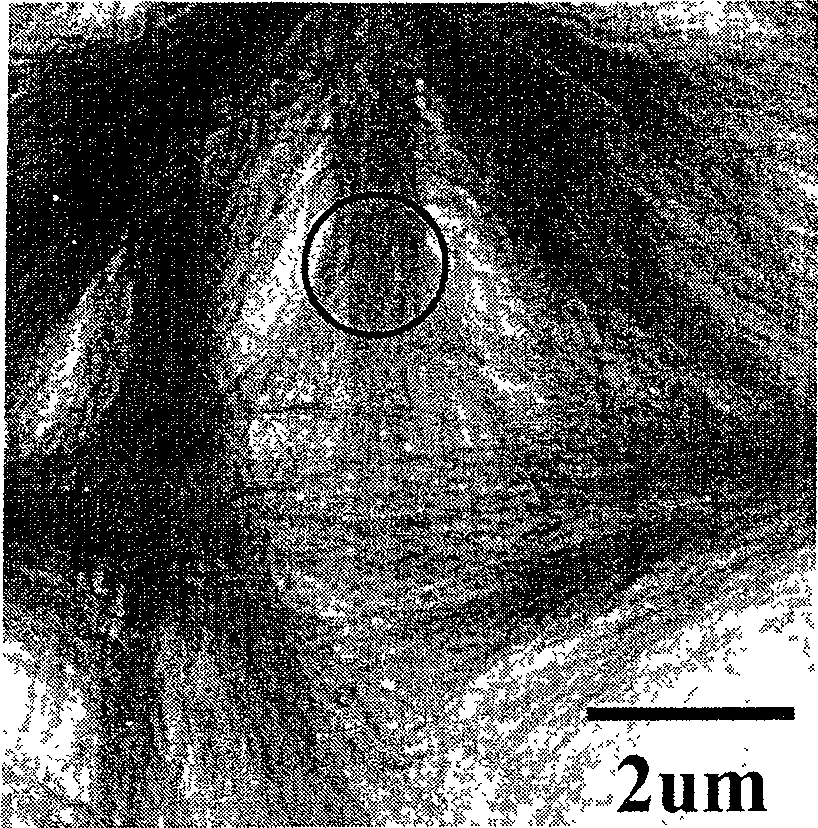

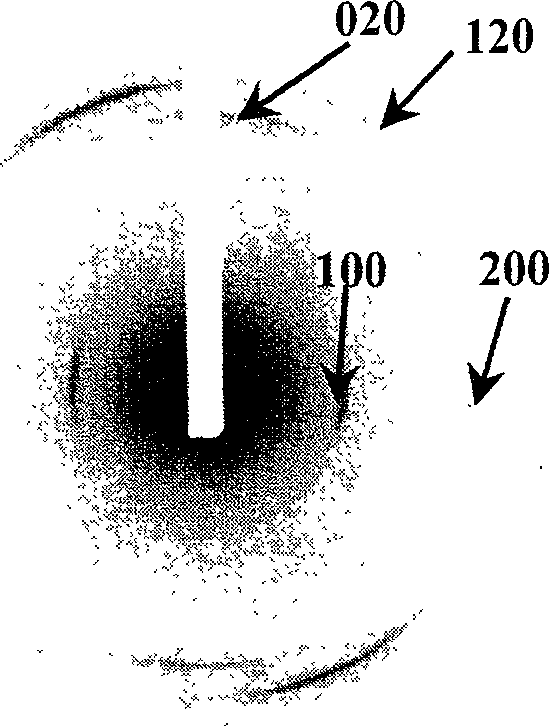

Image

Examples

Embodiment 1

[0023] Embodiment 1: be the carbon disulfide solution of the poly(3-butyl)thiophene that concentration is 5 mg / ml, spin coating under room temperature condition, volatilize solvent, obtain film, this film is in the carbon disulfide atmosphere of 0.98 times of saturated vapor pressure After standing for 20 minutes, a highly ordered polythiophene film was obtained.

Embodiment 2

[0024] Embodiment 2: adopt doctor blade to form film. The rest of the conditions and steps are the same as in Example 1 to obtain a highly ordered polythiophene film.

Embodiment 3

[0025] Embodiment 3: Printing into a thin film is adopted. The rest of the conditions and steps are the same as in Example 1 to obtain a highly ordered polythiophene film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com