Desulfurization and denitration integrated device

A desulfurization, denitrification and denitrification technology, which is applied in the direction of gas treatment, chemical instruments and methods, and the separation of dispersed particles, can solve the problems of uneven mixing of flue gas and reducing agent, low utilization rate of carbon-based catalysts, and uneven air distribution. Achieve high adsorption performance and reactivity, reduce investment and operating costs, and accelerate the denitrification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

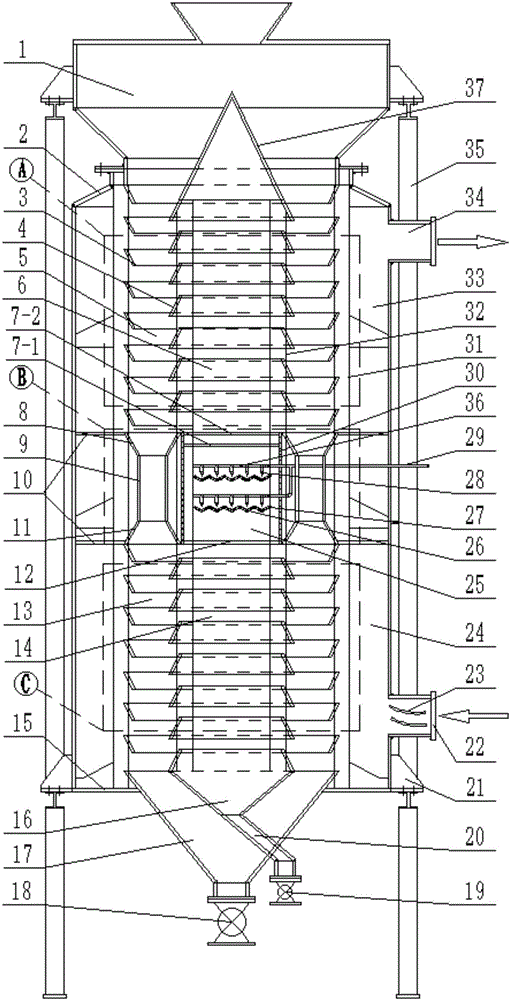

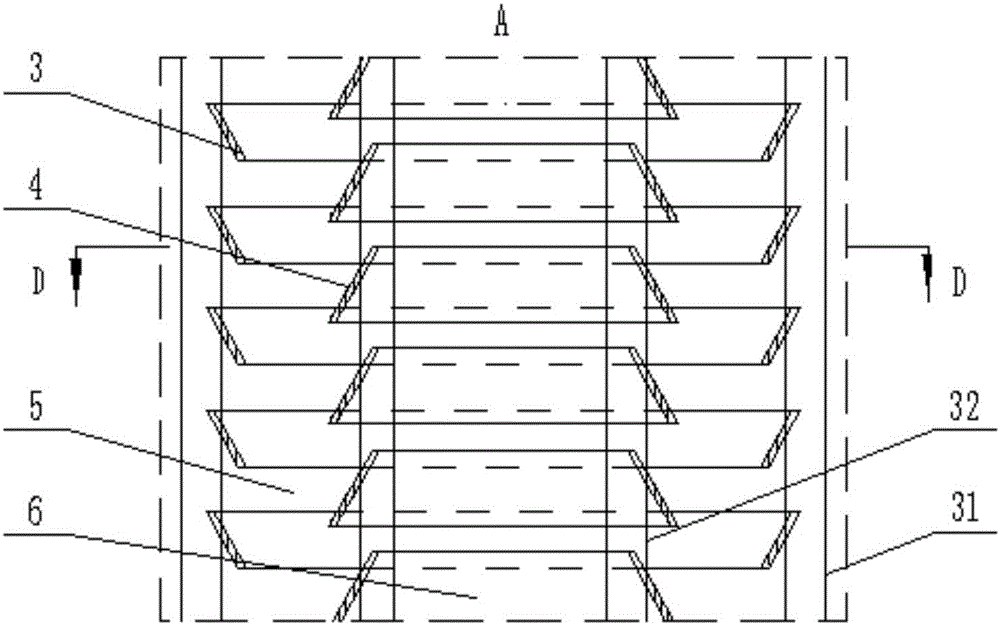

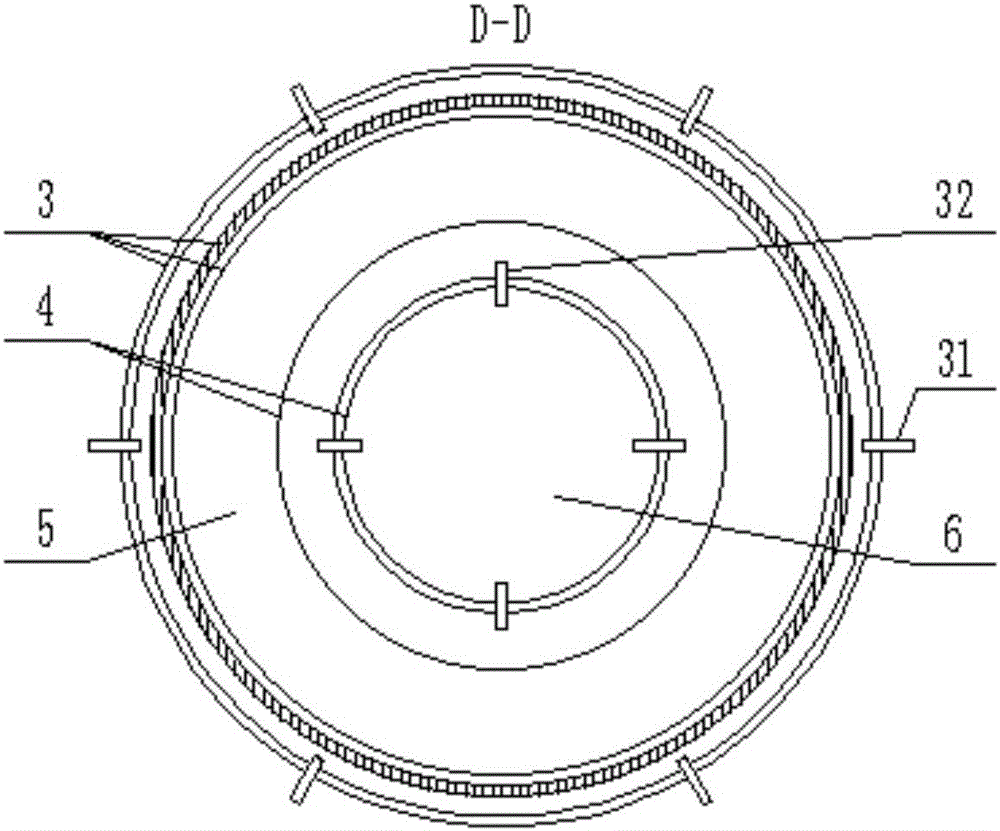

[0033]An integrated device for desulfurization and denitrification includes a top silo 1, a shell 2, an ammonia injection main pipe 29, a denitrification chamber 5, an air inlet 22, an exhaust port 34, a discharge valve 18, and a bracket 35. It is characterized in that the shell 2 The top of the tank is provided with a top silo 1, and the shell 2 is divided into three parts: the upper denitrification zone, the middle buffer zone and the lower desulfurization zone by the upper and lower annular partitions 10; chamber 5 and the denitrification air inlet chamber 6, the denitrification chamber 5 is composed of a plurality of inverted truncated hollow cones 3 and a plurality of truncated hollow cones 4, each inverted truncated hollow cone 3 is connected by an outer connecting rod 31, and each flat The truncated hollow cone 4 is connected by an inner connecting rod 32, the inverted truncated hollow cone 3 and the truncated hollow cone 4 are vertically staggered, the denitrification c...

Embodiment 2

[0049] The inclination angle of the inverted truncated hollow cone 7 is 120°, the interval between the adjacent inverted truncated hollow cones 7 is 78mm, and the inclination angle of the truncated hollow cones 9 is 60°, between the adjacent truncated hollow cones 9 The interval between them is 43mm, the vertical distance between the adjacent ammonia injection branch pipes 36 in the ammonia mixing cylinder wall 30 is 220mm, the horizontal distance between the adjacent nozzles 28 of the same ammonia injection layer is 100mm, and the rectangular hole of the equalizer plate 12 is 5*30mm, the aperture of the first rectifying plate 7-1 is 10mm, and the opening rate is 47.21%, the aperture of the second rectifying plate 7-2 is 8mm, and the opening rate is 50.91%, and the rest is the same as that of embodiment 1.

Embodiment 3

[0051] The inclination angle of the inverted truncated hollow cone 7 is 115 °, the interval between the adjacent inverted truncated hollow cones 7 is 63 mm, and the inclination angle of the truncated hollow cones 9 is 65 °, between the adjacent truncated hollow cones 9 The interval between them is 55mm, the vertical distance between the adjacent ammonia injection branch pipes 36 in the ammonia mixing cylinder wall 30 is 160mm, the horizontal distance between the adjacent nozzles 28 of the same ammonia injection layer is 75mm, and the rectangular hole of the equalizer plate 12 is 4*23mm, the aperture of the first rectifying plate 7-1 is 8mm, and the opening rate is 30.8%, the aperture of the second rectifying plate 7-2 is 6mm, and the opening rate is 37.4%, and the rest is the same as that of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com