Low NOx cyclone micro-oil coal powder burner

A pulverized coal burner and burner technology are applied in burners, burners for burning powder fuel, combustion methods, etc., to achieve the effects of saving fuel oil and reducing pollutant emissions

Inactive Publication Date: 2008-10-22

杭州意能节能技术有限公司

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to solve the defects of the prior art, the present invention provides a low-NOx swirling micro-oil pulverized coal burner in which a large amount of NOx is reduced during ignition and combustion

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

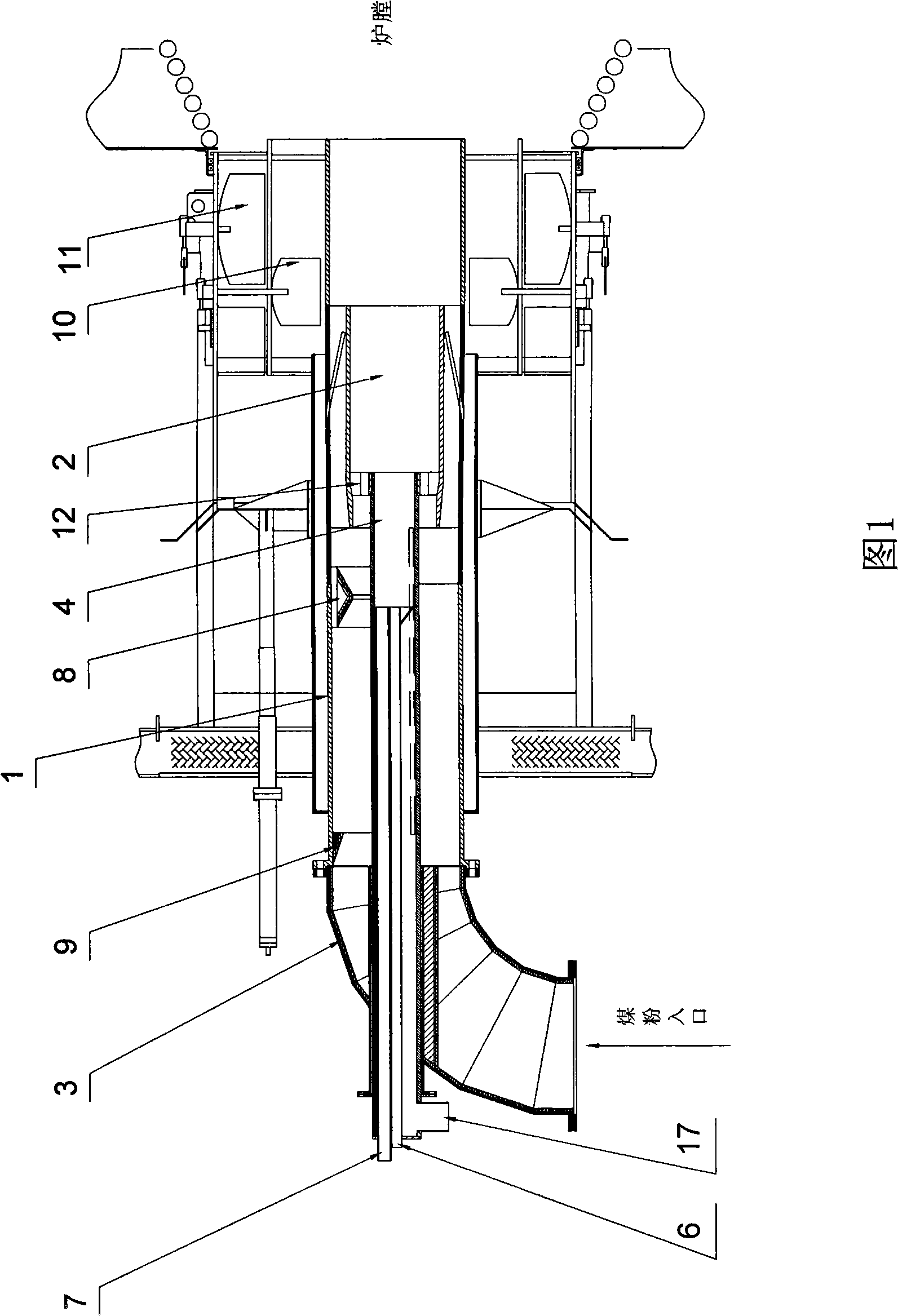

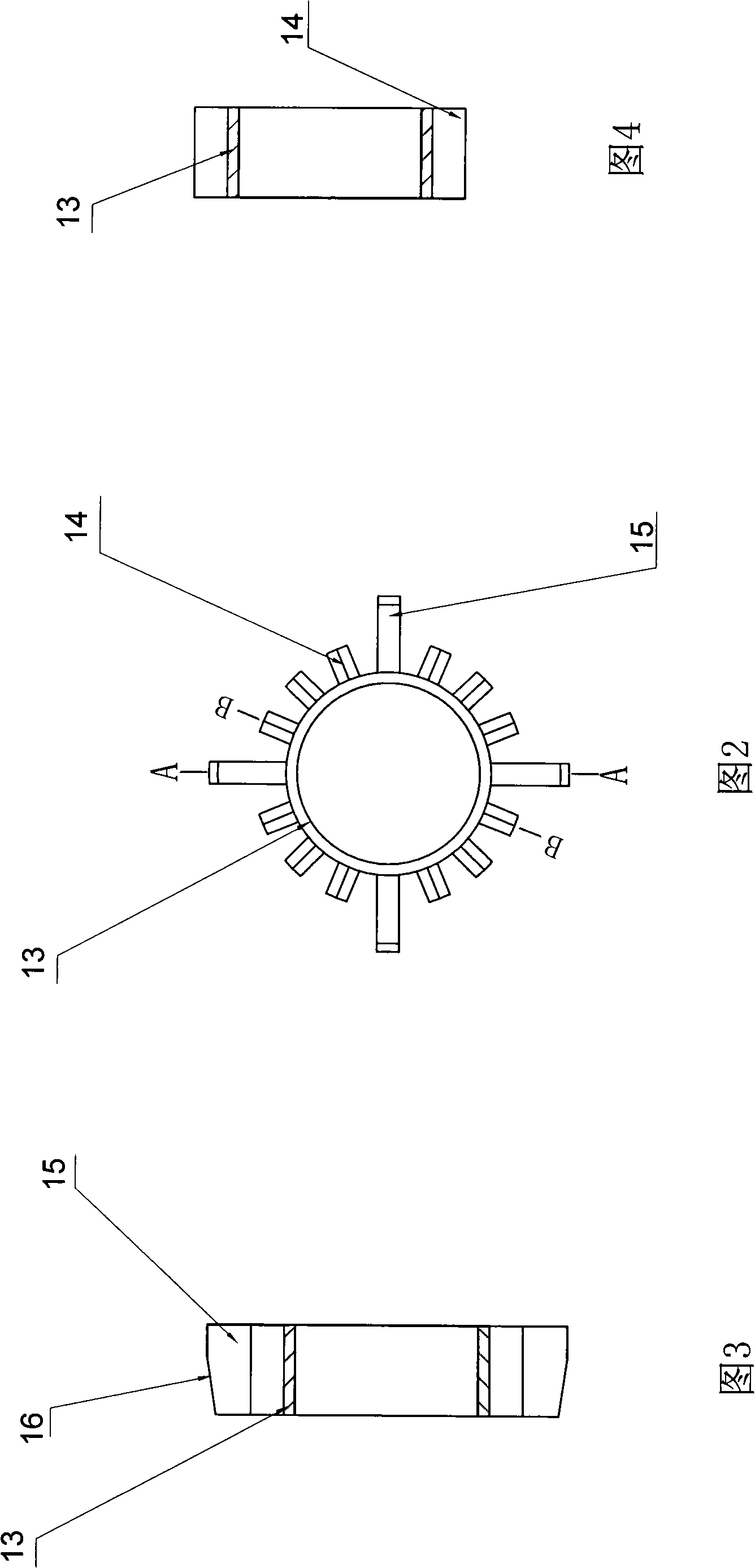

Aiming at the disadvantages that the prior cyclone pulverized coal burner can not effectively reduce the emission amount of NOx, the invention provides a low-NOx cyclone micro-oil pulverized coal burner which reduces mass NOx in the igniting and burning process. The low-NOx cyclone micro-oil pulverized coal burner comprises a burner body and a primary pulverized coal burning chamber arranged inside the burner body; an inlet of the burner body is connected with an elbow piece; an inlet of the primary pulverized coal burning chamber is provided with an oil burning chamber which is inserted into the primary pulverized coal burning chamber from the elbow piece; the burner body is provided inside with a pulverized coal concentrated ring; an outlet of the burner body is provided with a secondary wind port inside the cyclone and a secondary wind port outside the cyclone; an outlet of the oil burning chamber and an inlet of the primary pulverized coal burning chamber are provided with a pulverized coal distributor. The burner can use a small quantity of fuel to ignite the pulverized coal in the burning chamber; the pulverized coal in the burning chamber has large concentration in order that the burning is in reducing atmosphere and mass NOx is deacidized, thereby reducing the emission of pollutant.

Description

A low NOx swirling micro-oil pulverized coal burner technical field The invention belongs to a pulverized coal burner, in particular to a pulverized coal burner with low NOx swirling flow and fine oil. Background technique In the pulverized coal boiler, the thick-lean combustion technology is often used, that is, the pulverized coal flow into the furnace is inertially separated, divided into two streams of thick and thin, and then sent to the furnace respectively. It has been significantly improved, and its ignition characteristics have been significantly improved. However, when the pulverized coal is burned in the burner, it will produce atmospheric pollutants NOx, which will cause serious harm to environmental pollution and human health, especially for poor-quality combustion. For difficult-to-combust fuels such as bituminous coal and lean coal, it is more difficult to meet the requirements of low NOx emissions. In the existing swirl pulverized coal burner, an internal ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F23D1/02

Inventor 李凤瑞

Owner 杭州意能节能技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com