Multifunctional cooking utensil

A cooking utensil and multi-functional technology, which is applied in the field of multi-functional cooking utensils, can solve problems such as damage to motors or components, and affect the service life of multi-functional cooking utensils, and achieve the effects of improving thermal efficiency, ensuring safety in use, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

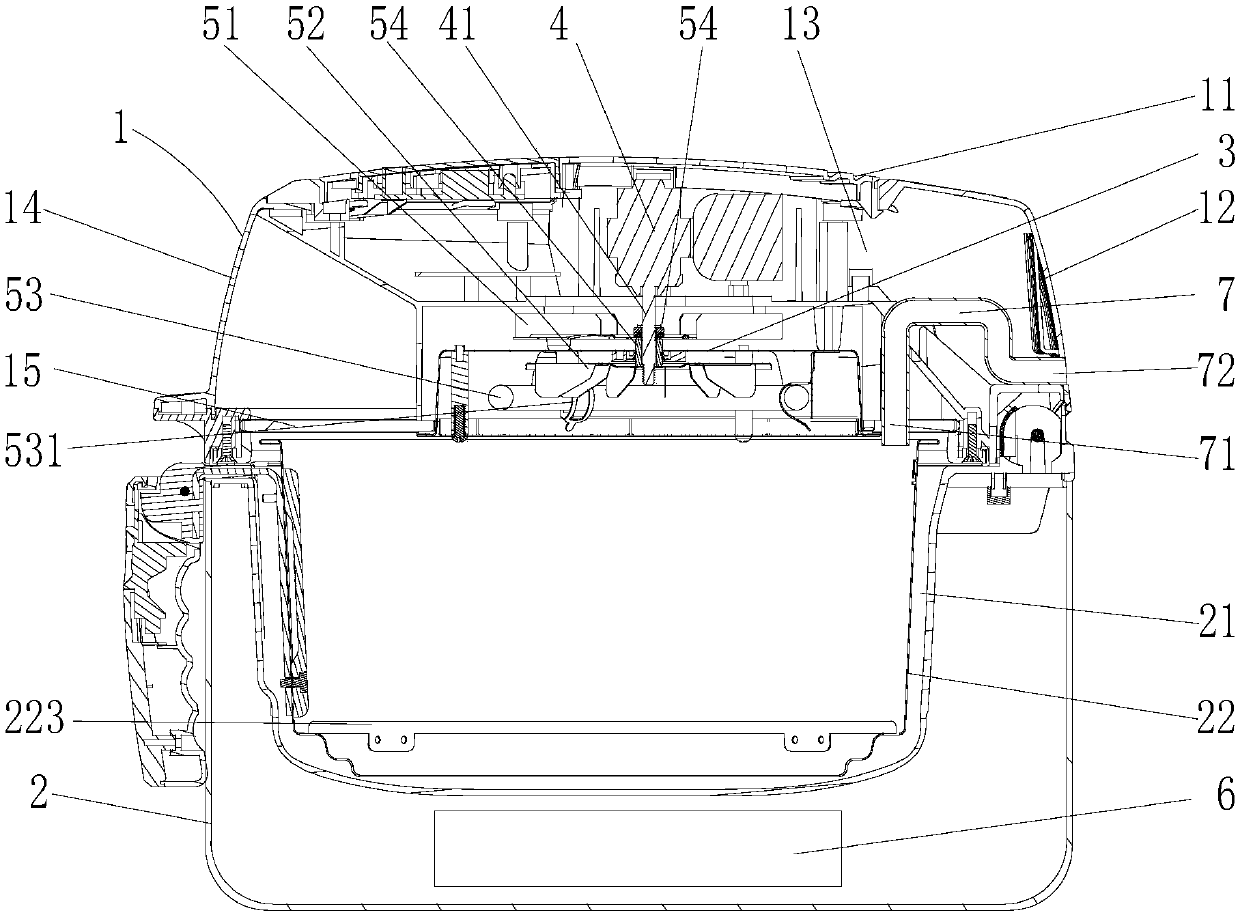

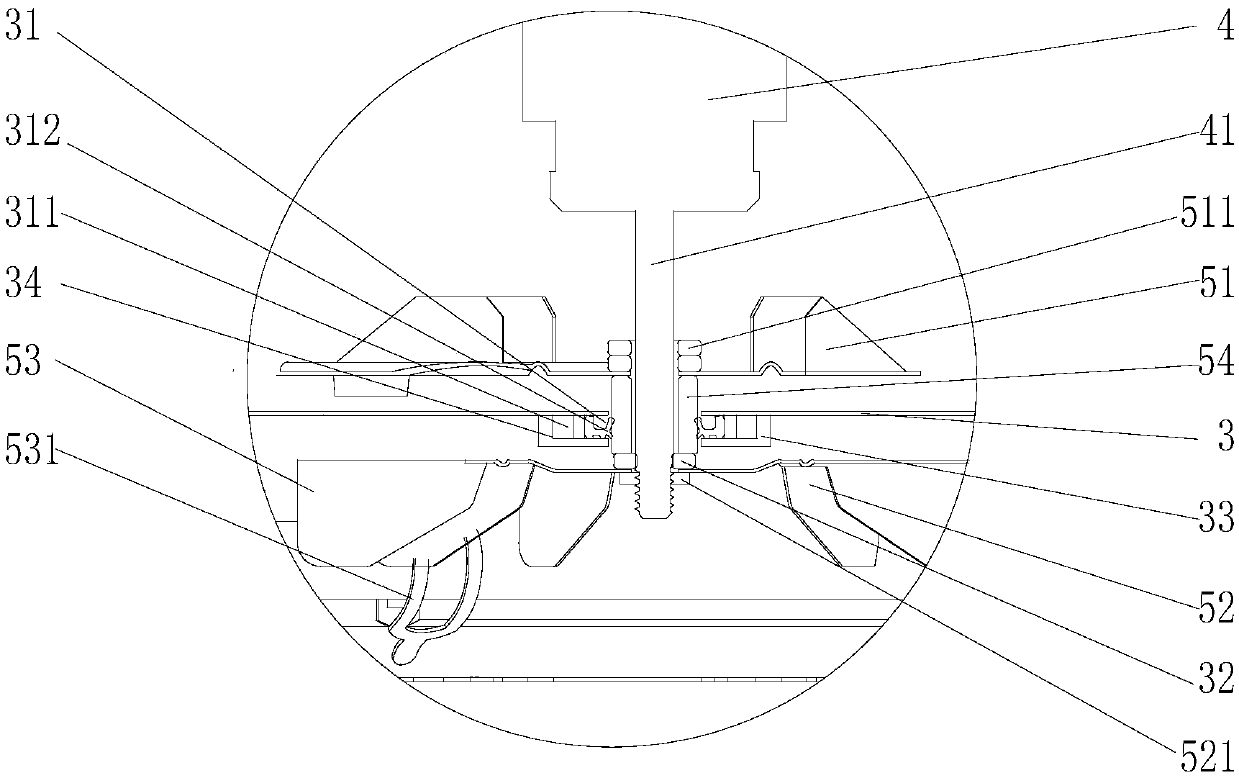

[0039] The structure of the multifunctional cooking appliance of the present embodiment is as follows: Figure 1 to Figure 2 As shown, the multifunctional cooking appliance includes an upper casing 1 and a lower casing 2, both of which are heat-resistant plastic casings, and the upper casing 1 is covered on the lower casing 2. In this embodiment The upper casing 1 and the lower casing 2 of the example are hinged to each other, the upper casing 1 is arranged above the lower casing 2 through a hinge shaft, and the upper casing 1 is provided with an air inlet 11 and an air outlet 12, and the air inlet 11 is located on the upper casing. The top of the body 1 has a short air intake path, so that the outside air quickly enters the cold air cavity 13 to dissipate heat for the motor, improving heat dissipation efficiency. The air outlet 12 is located on the rear side of the upper housing 1 to reduce the impact of the air on the user. A wind guide cover 3 is arranged under the upper sh...

Embodiment 2

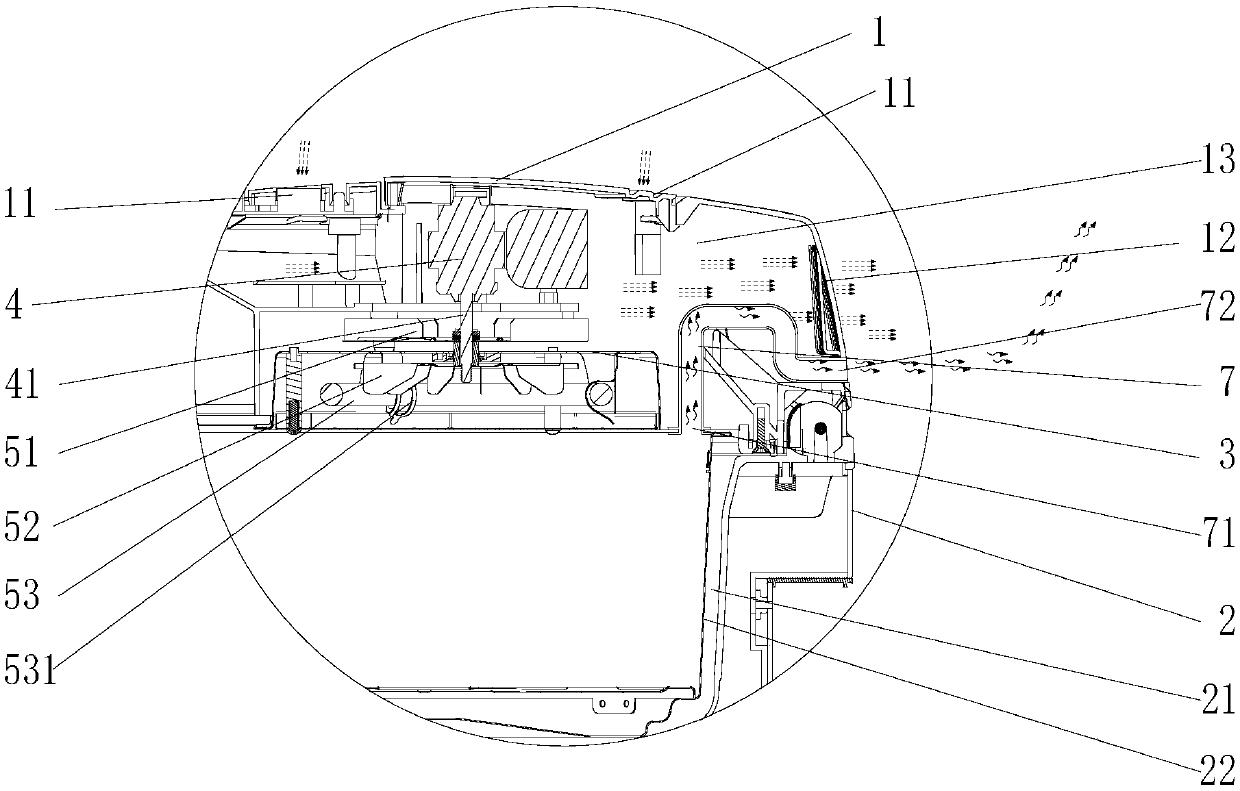

[0051] The difference between this embodiment and Embodiment 1 lies in the specific structure of the steam exhaust channel, combined with image 3As shown, the second communication port 72 of the steam exhaust passage 7 of this embodiment is located on the upper casing 1 and is located on a different side from the air inlet 11, specifically, the air inlet 11 is located on the top of the upper casing 1, that is, on the top of the cover 14 To communicate with the cold air chamber 13, the second communication port 72 is located at the side of the upper case 1, that is, at the side of the cover body 14 to communicate with the outside world, so that the second communication port 72 and the air inlet 11 are on different sides of the upper case 1 Set to reduce the probability that the steam discharged from the second communication port 72 will enter the cold air chamber 13 through the air inlet 11 and damage the motor 4 and components, and the air inlet 11 is located on the top of the...

Embodiment 3

[0061] The difference between this embodiment and Embodiment 1 or Embodiment 2 is that a condensed water box 16 is provided on the side of the upper casing 1, combined with Figure 4 As shown, the condensed water box 16 of this embodiment is detachably installed, and the condensed water box 16 is set on the same side as the second communicating port 72 and is located below the second communicating port 72, most of the steam will pass through the second communicating port 72 However, a small amount of steam will still form condensed water when it is cooled. At this time, the condensed water generated by the steam will be collected downwards at the second communication port 72 and enter the condensed water box 16 to prevent the condensed water from The outer walls of the upper casing 1 and the lower casing 2 drip onto the table, which improves the experience of the user.

[0062] Other structures and beneficial effects of this embodiment are the same as those of Embodiment 1 or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com