Solar cell wafer and printing screen thereof

A technology of solar cells and printing screens, which is applied in the field of solar cells, can solve problems such as roughness, silicon chip cracks, and hidden cracks, and achieve the effects of increasing the adjustment range, improving conversion efficiency, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

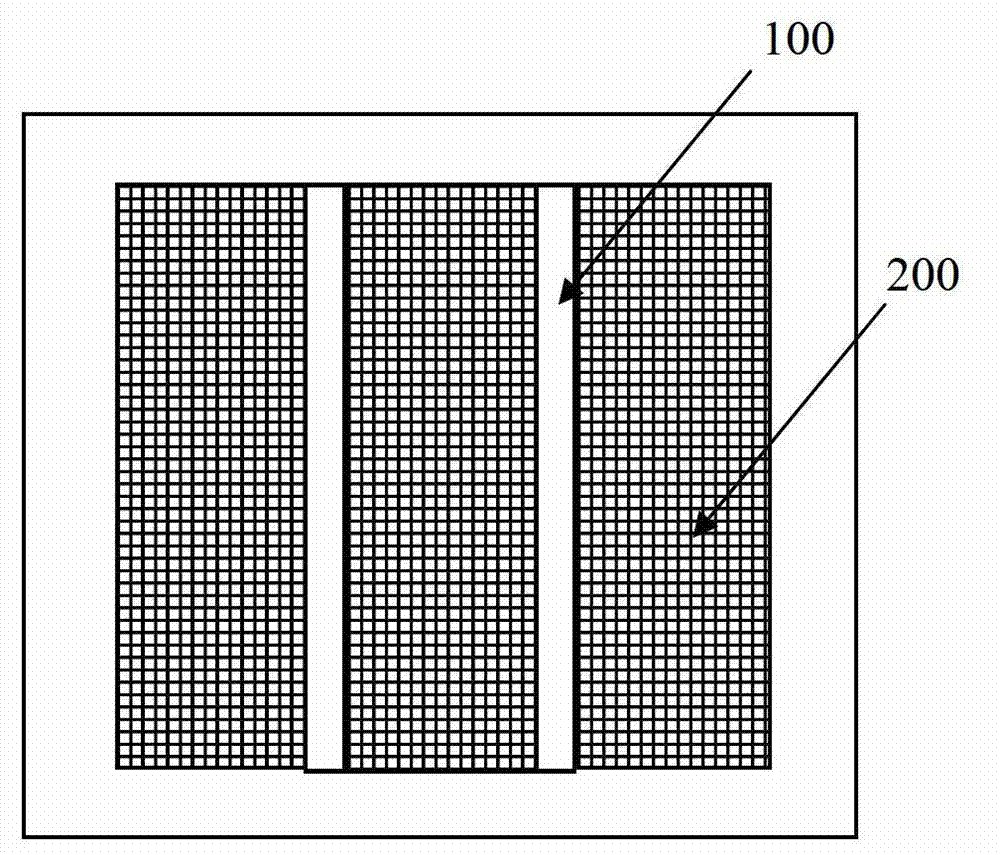

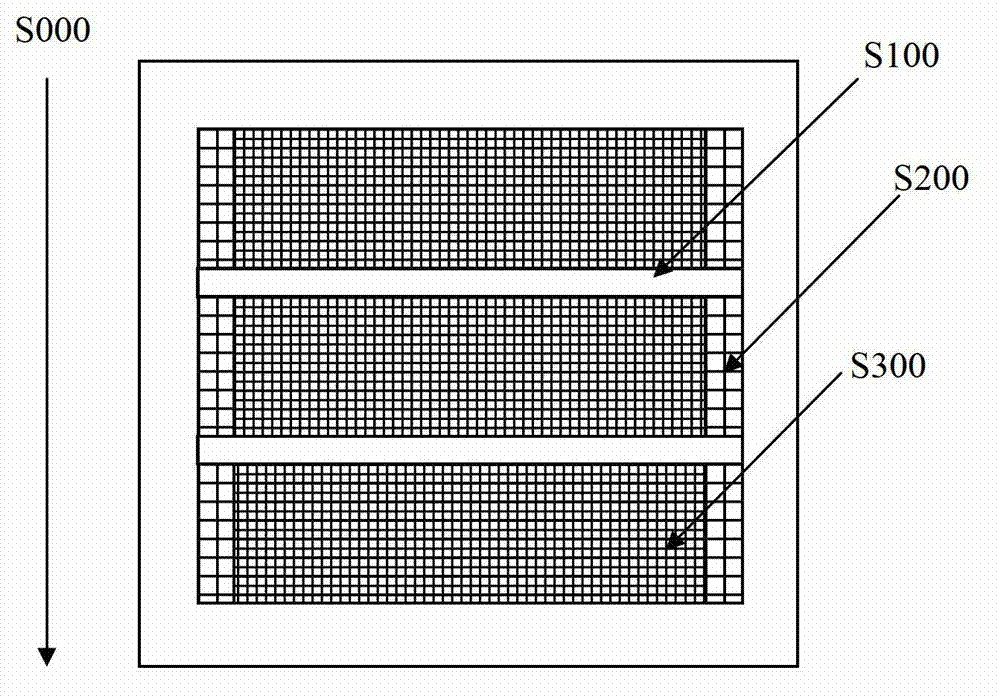

[0036] This embodiment provides a printing screen, its schematic diagram is as follows image 3 As shown, S000 represents the printing direction of the squeegee. Except for the non-hollowed part of the main grid S100, the screen meshes of the two edge hollowed out areas S200 parallel to the printing direction S000 are smaller than the screen meshes of other hollowed out areas S300, that is, each The screen mesh area of the edge hollow area is smaller than the screen mesh area of other hollow areas. Wherein, the wire mesh is a wire mesh or a non-metal mesh.

[0037] The two edge hollow areas of the silk screen described in this embodiment are the area 2mm-8mm away from the edge of the screen, including the endpoint value, and the mesh number of each edge hollow area is 250 mesh / cm-325 mesh / cm , the mesh number of other hollow areas is 350 mesh / cm-400 mesh / cm. That is to say, in the two edge hollow areas, the screen mesh area of each edge hollow area is 0.31mm 2 -0.4mm ...

Embodiment 2

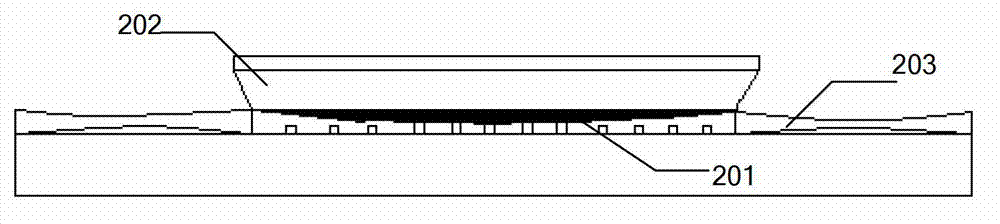

[0040] This embodiment provides a solar battery sheet, the aluminum back field of the solar battery sheet is printed using the printing screen described in the above embodiment, wherein the thickness of the aluminum back field of the entire solar battery sheet is uniform.

[0041]The preferred solar cells in this embodiment are N-type solar cells or P-type solar cells.

[0042] The aluminum back field of the solar cells in this embodiment is printed using the printing screen described in the above embodiments, so that the thickness of the aluminum back field printed on the entire silicon wafer is uniform, and the adjustment range of the sintering temperature is increased, so that the sintering temperature can be adjusted. By increasing the sintering temperature, the surface electrical contact ability between the front electrode, the back electrode and the back electric field of the solar cell is improved, and finally the conversion efficiency of the solar cell is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com