Aluminium paste for preparing crystal silicon solar cell aluminium back surface field and manufacture method thereof

A solar cell and aluminum back field technology, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problem of reducing the photoelectric conversion efficiency of batteries, affecting the quality of battery production, and unfavorable industrial production, etc. Problems, to achieve high photoelectric conversion efficiency of the battery, improve photoelectric conversion efficiency and adhesion, and improve the effect of photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

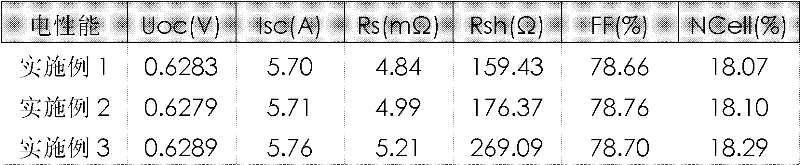

Embodiment 1

[0039] An aluminum paste for preparing an aluminum back field of a crystalline silicon solar cell, the implementation process is as follows:

[0040] (1) Preparation of organic vehicle: 6% of terpineol, 4% of tributyl citrate, 2% of ethyl cellulose, 1% of leveling agent, 0.5% of surfactant, anti-settling agent according to the mass percentage of slurry 1%, defoamer 0.5%, weigh each component, after the weighing is completed, heat the mixture to 60°C in a water bath, and then stir with an electric mixer until all the organic matter dissolves in each other to obtain an organic carrier;

[0041] (2) Preparation of inorganic glass frit: by mass percentage Bi 2 o 3 20%, SiO 2 15%, ZnO 20%, SnO 2 15%, Al 2 o 3 10%, Sb 2 o 3 15%, MnO 2 2%, K 2 O 3% is formulated into oxide mixed powder, and then mixed in a V-type blender for 4 hours to mix evenly. The uniformly mixed powder material is added into a corundum crucible, heated in a high-temperature furnace to 1500° C. for 20 m...

Embodiment 2

[0046] An aluminum paste for preparing an aluminum back field of a crystalline silicon solar cell, the implementation process is as follows:

[0047] (1) Preparation of organic carrier: 9% terpineol by mass percentage, 1% tributyl citrate, 5% ethyl cellulose, 1% leveling agent, 0.3% surfactant, 0.5% anti-sedimentation agent, Defoamer 0.2% Weigh each component Weigh each component, after the weighing is completed, heat the mixture to 60°C in a water bath, and then stir it with an electric mixer until all the organic matter dissolves in each other to obtain an organic carrier.

[0048] (2) Preparation of inorganic glass frit: by mass percentage Bi 2 o 3 50%, SiO 2 10%, ZnO 30%, SnO 2 2%, Al 2 o 3 3%, Sb 2 o 3 2%K 2 O 1%, CaO 2%, MnO 2 1% is formulated as oxide mixed powder, and then mixed in a V-type blender for 4 hours to mix evenly. The uniformly mixed powder material is added into a corundum crucible, heated in a high-temperature furnace to 1400° C. for 20 minutes, ...

Embodiment 3

[0053] An aluminum paste for preparing an aluminum back field of a crystalline silicon solar cell, the implementation process is as follows:

[0054] (1) Preparation of organic carrier: by mass percentage terpineol 3%, tributyl citrate 7%, ethyl cellulose 3%, leveling agent 0.5%, surfactant 0.4%, anti-settling agent 1%, Defoamer 0.1% Weigh each component, after the weighing is completed, heat the mixture to 60°C in a water bath, and then stir with an electric mixer until all organic matter dissolves in each other to obtain an organic carrier.

[0055] (2) Preparation of inorganic glass frit: by mass percentage Bi 2 o 3 40%, SiO 2 5%, ZnO 40%, SnO 2 7%, Al 2 o 3 1%, Sb 2 o 3 3%, BaO 1%, MnO 2 3% is formulated as oxide mixed powder, and then mixed in a V-type blender for 4 hours to mix evenly. The uniformly mixed powder material is added into a corundum crucible, heated in a high-temperature furnace to 1450° C. for 20 minutes, and then water-quenched to obtain glass gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com