Organic adhesive for aluminum paste of silicon solar cells and preparation method thereof

A technology of silicon solar cells and organic adhesives, applied in the direction of adhesive types, cellulose adhesives, adhesives, etc., can solve the problem of poor uniformity and continuity of back field electrodes, poor film density, and reduced yield, etc. problem, to achieve good wetting and dispersing performance, simple process method, and reduce the tendency of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

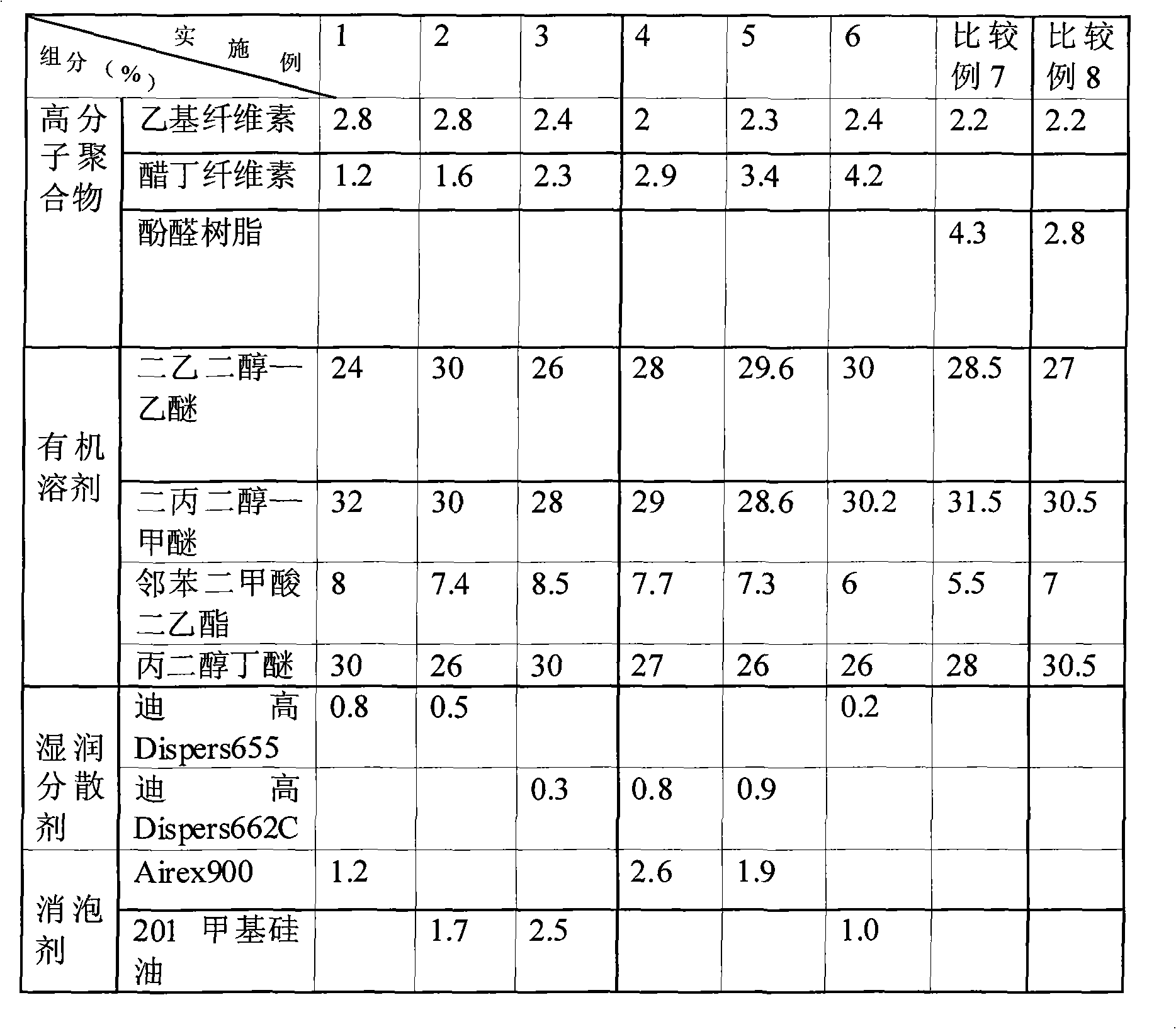

[0030] The components of the organic binder are: by mass parts ethyl cellulose 2.8%, acetate butyl cellulose 1.2%, diethylene glycol-ether 24%, dipropylene glycol-methyl ether 32%, diethyl phthalate 8.0%, Propylene Glycol Butyl Ether 30%, Tego Dispers655 0.8%, Airex 900 1.2%. The above composition is shown in Example 1 in Table 1, and the components in Table 1 are percentages by mass.

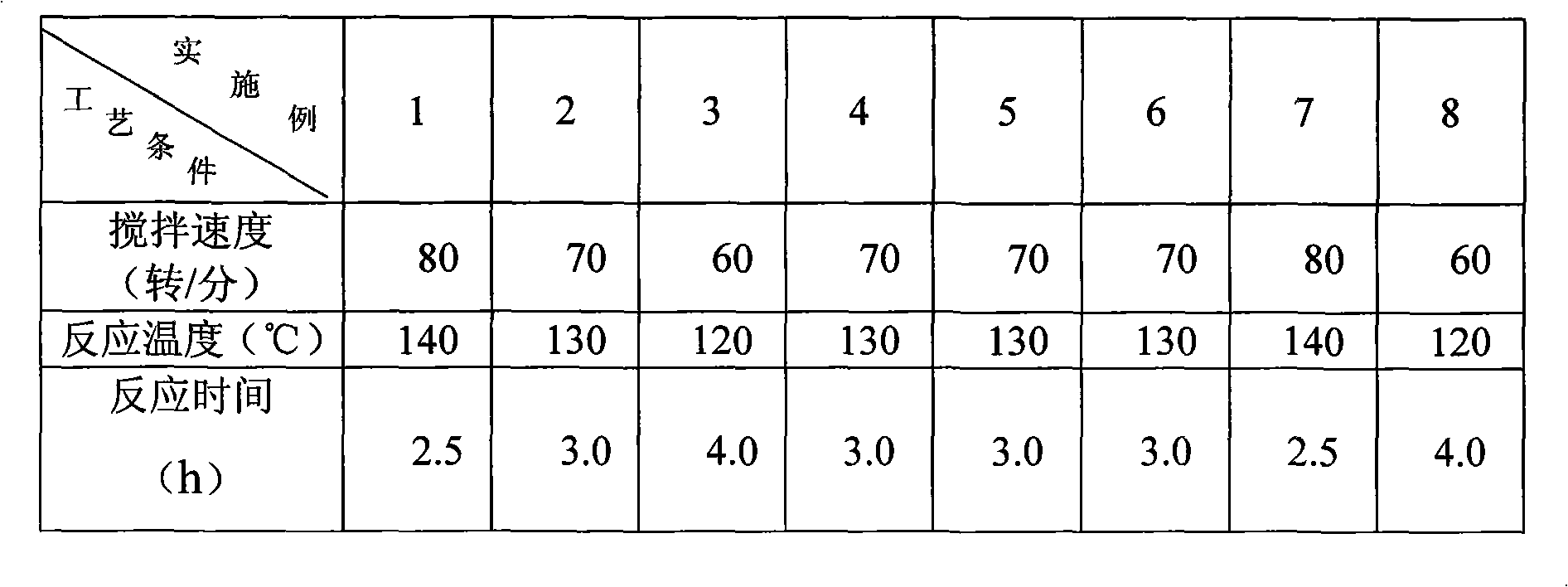

[0031] Organic adhesive preparation steps: Put the above components into a stainless steel reaction kettle, heat up with electric heating, start the agitator, and stir at a speed of 80 rpm, and wait for the solution in the reaction kettle to heat up to 140°C and keep the temperature for 2.5 hours. Uniformly mix and fully react in the reaction kettle. After the obtained reactants are cooled, they are filtered with a 200-mesh screen to obtain finished organic adhesives for silicon solar cell aluminum paste. The above-mentioned preparation process conditions are shown in Example 1 in Table 2.

[...

Embodiment 2- Embodiment 6

[0044] The component amounts of the organic binder, the preparation steps and the test results related to the performance indicators of the organic binder of the present invention are shown in Table 1, Table 2 and Table 3 respectively, and the description of the rest of the process is the same as that of Example 1.

[0045] Table 2

[0046]

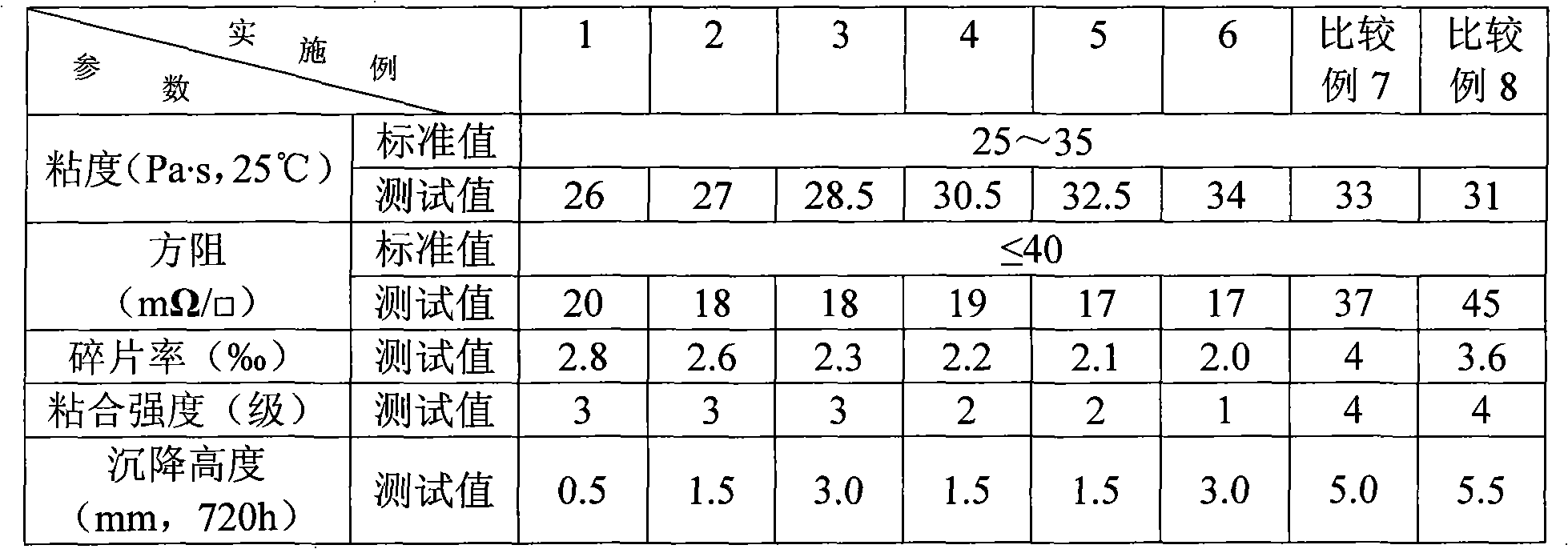

[0047] table 3

[0048]

[0049] Note: The bonding strength is grade 1, the bonding strength is better, and the bonding strength decreases with the increase of the grade.

[0050] From the test data of table 3 embodiment 1-6 and comparative example 7-8 as seen:

[0051] The silicon solar cell aluminum paste prepared by the organic binder of the present invention comprising acetobutylcellulose and ethyl cellulose, after drying (before sintering), the fragmentation rate of silicon wafers is significantly reduced, that is, effectively reduced The stress produced on the silicon wafer; and the adhesive strength of the aluminum paste fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com