P-type PERC double-faced solar cell employing laser marking alignment and preparation method thereof

A solar cell and laser marking technology, applied in the field of solar cells, can solve the problems of defective rate of double-sided PERC solar cells, inaccurate printing of aluminum paste, inaccurate positioning, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

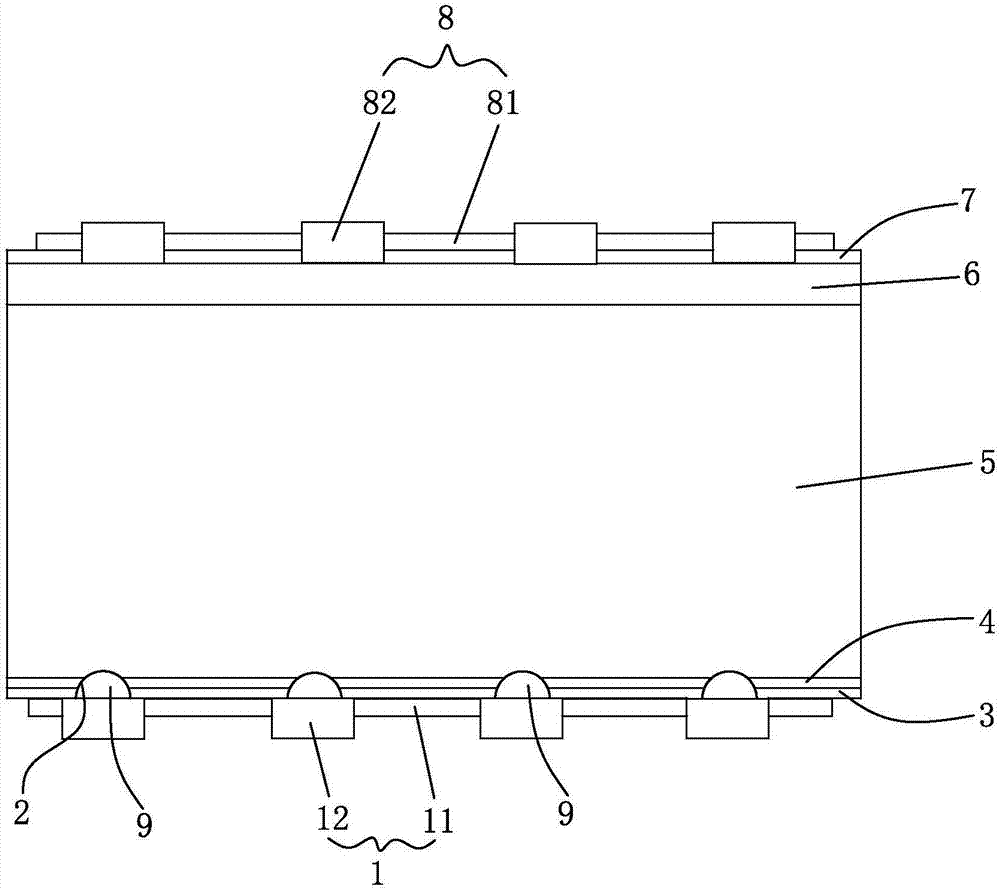

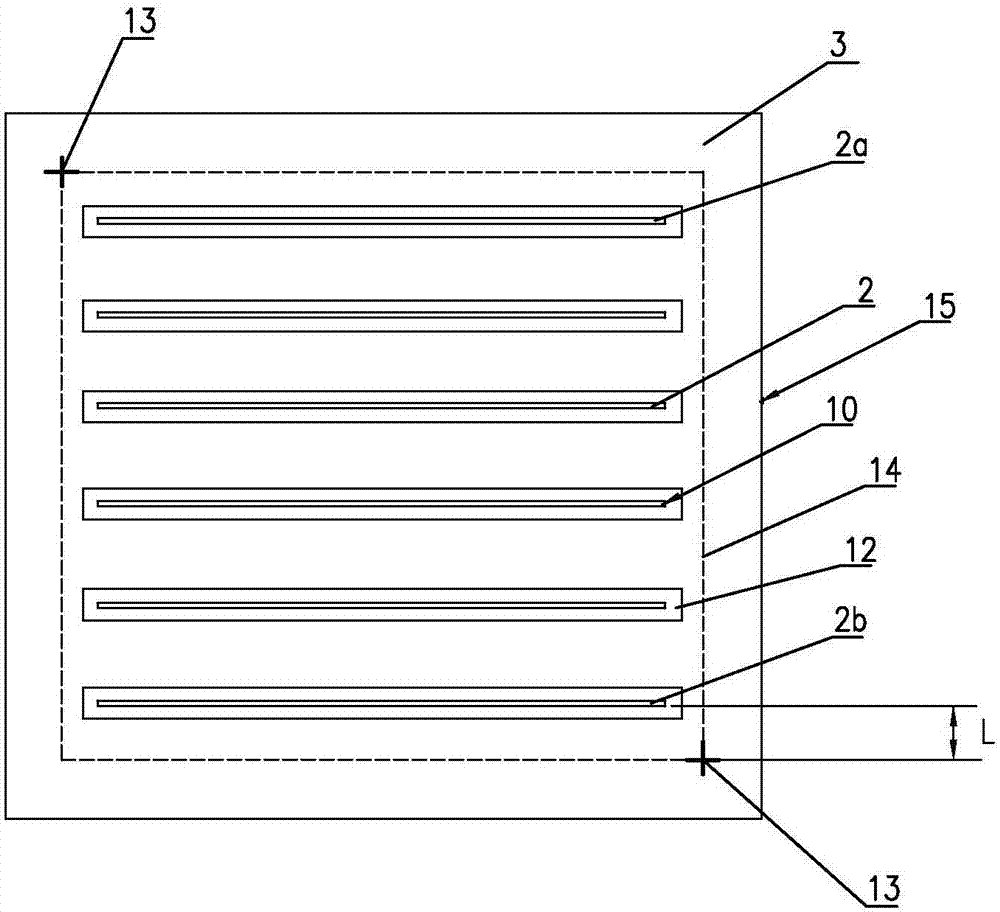

[0044] Such as figure 1 and 2As shown, it is a P-type PERC double-sided solar cell that adopts laser marking alignment according to the present invention, including a back electrode 1, a back silicon nitride film 3, an aluminum oxide film 4, a P-type silicon 5, The N-type emitter 6, the front silicon nitride film 7 and the front silver electrode 8, the front silver electrode 8 is mainly formed by connecting the front silver electrode sub-grid 82 and the front silver electrode main grid 81 which are vertically intersecting. The back silver electrode 1 is mainly formed by connecting the back main grid line 11 and the back aluminum grid line 12 which are vertically intersecting. On the back silicon nitride film 3, there are several holes penetrating the back silicon nitride film 3 and the aluminum oxide film 4. Groove 2 constitutes laser grooved area 10, P-type silicon 5 is exposed in groove 2, the part 9 of back aluminum gate line 12 located in groove 2 is connected with P-type...

Embodiment 2

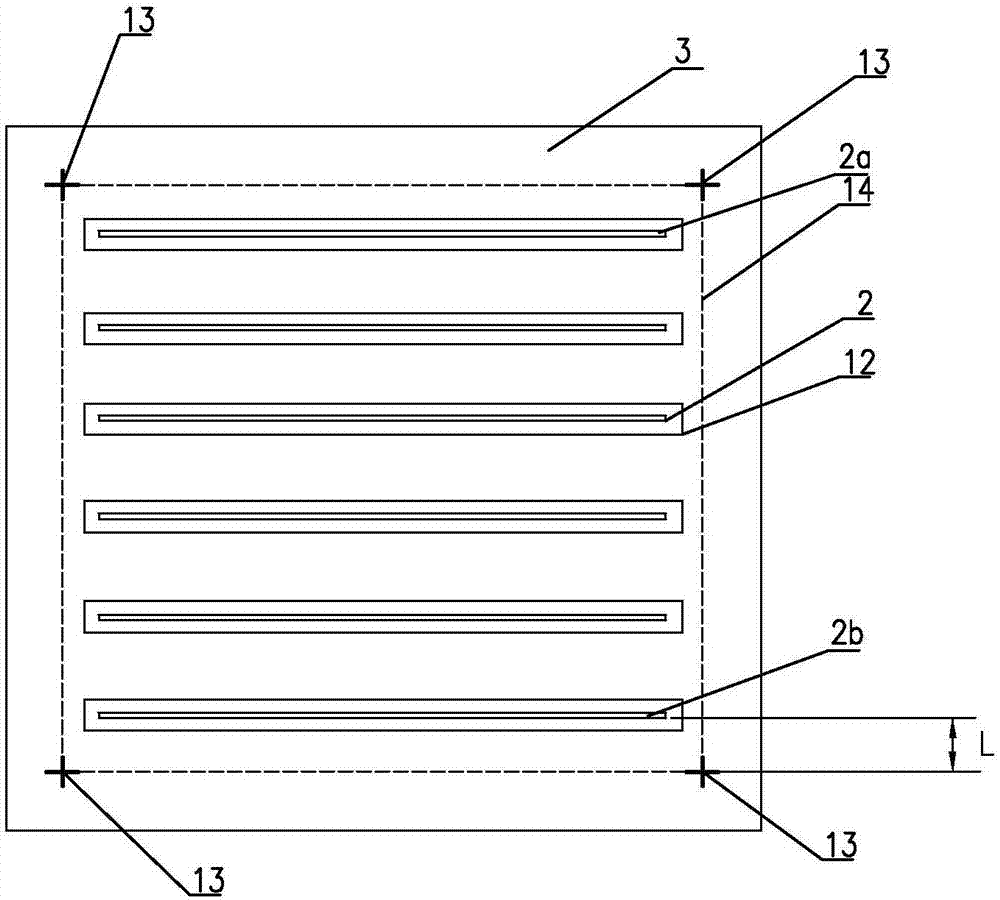

[0059] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that there are four laser marks 13 located at the four corners of the solar cell 15 , and all the laser marks 13 are located on the same square 14 .

[0060] A method for preparing the above-mentioned P-type PERC double-sided solar cell using laser marking alignment, comprising the following steps:

[0061] (1) Form a suede surface on the front side of the P-type silicon 5;

[0062] (2) Diffusion is performed on the front side of the product obtained in step (1) to form an N-type emitter 6;

[0063] (3) Remove the phosphosilicate glass and surrounding PN junctions formed by the product obtained in step (2) during the diffusion process, and after polishing the back, turn to step (4);

[0064] (4) Deposit an aluminum oxide film 4 and a silicon nitride film 3 on the back in sequence on the back side of the product obtained in step (3), and then deposit a front silicon nitride film 7 on ...

Embodiment 3

[0072] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that there are two laser marks 13 , which are respectively close to opposite sides of the solar cell 15 , and all the laser marks 13 are located on the same square 14 .

[0073] A method for preparing the above-mentioned P-type PERC double-sided solar cell using laser marking alignment, comprising the following steps:

[0074] (1) Form a suede surface on the front side of the P-type silicon 5;

[0075] (2) Diffusion is performed on the front side of the product obtained in step (1) to form an N-type emitter 6;

[0076] (3) Remove the phosphosilicate glass and surrounding PN junctions formed by the product obtained in step (2) during the diffusion process, and after polishing the back, turn to step (4);

[0077] (4) Deposit an aluminum oxide film 4 and a silicon nitride film 3 on the back in sequence on the back side of the product obtained in step (3), and then deposit a front silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com