All Al-BSF crystal silicon cell and preparation method thereof

A technology of crystalline silicon battery and all-aluminum back field, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of unfavorable product market competitiveness, increase the preparation process, increase production cost, etc., and achieve improved field passivation characteristics, Effect of improving spectral response and improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

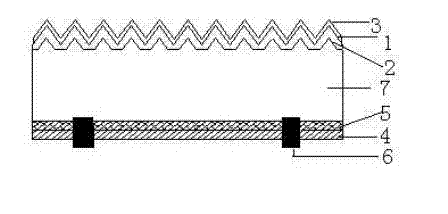

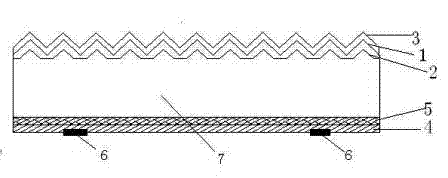

[0047] A kind of all-aluminum back field crystalline silicon cell, such as figure 2 As shown, a silicon layer 7 is included, and a P+ passivation layer 5 and an aluminum back conductive layer 4 are laminated on the back of the silicon layer 7 in sequence, and a back electrode 6 is provided on the aluminum back conductive layer 4 .

[0048] The back electrode 6 is a tin electrode. The thickness of the aluminum back conductive layer is 10 microns-30 microns.

Embodiment 2

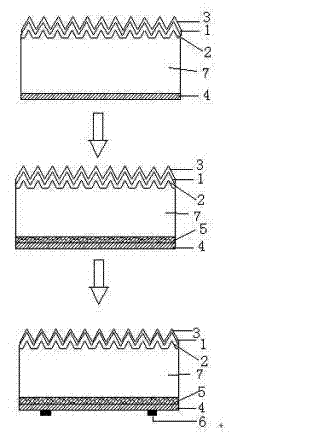

[0050] A method for preparing an all-aluminum back field crystalline silicon cell, the preparation process is as follows image 3 As shown, the steps are:

[0051] a) Attach aluminum paste on the back of the silicon nitride anti-reflective coating and dry it to form an aluminum back conductive layer with a thickness of 25 microns, and the drying temperature is 240 ° C;

[0052] b) Print a silver grid line on the surface of the silicon wafer to form a positive electrode and dry it at 200°C;

[0053] c) High temperature sintering, the sintering temperature is 850°C, to form a P+ passivation layer;

[0054] d) Attach tin paste on the conductive layer on the aluminum back as the back electrode and dry it at a temperature of 170°C;

[0055] e) Low temperature sintering, the sintering temperature is 300°C, so that the adhesion between the back electrode and the aluminum back conductive layer is 3N, and the preparation of the all-aluminum back field crystalline silicon cell is comp...

Embodiment 3

[0058] A method for preparing an all-aluminum back field crystalline silicon cell, the preparation process is as follows Figure 4 As shown, the steps are:

[0059]a) Attach aluminum paste on the back of the silicon nitride anti-reflection film layer and dry it to form an aluminum back conductive layer. The drying temperature is 250 ° C;

[0060] b) Print a silver grid line on the surface of the silicon wafer layer as a positive electrode and dry it at 200°C;

[0061] c) High temperature sintering, the sintering temperature is 900°C, to form a P+ passivation layer;

[0062] d) Use laser ablation, mechanical method or corrosion method to remove the surface layer on the aluminum back conductive layer at the position where the back electrode is attached to form a window for removing the surface layer, and the thickness of the removal layer is 0.1 μm-3 μm;

[0063] e) Screen-print silver paste on the conductive layer on the aluminum back as the back electrode and dry it. The sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com