Fuse-wires structure and forming method thereof

A fuse structure and fuse technology, which are applied in the manufacturing of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of increasing process costs, increasing masks, and incompatibility, and achieving the effect of increasing process costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

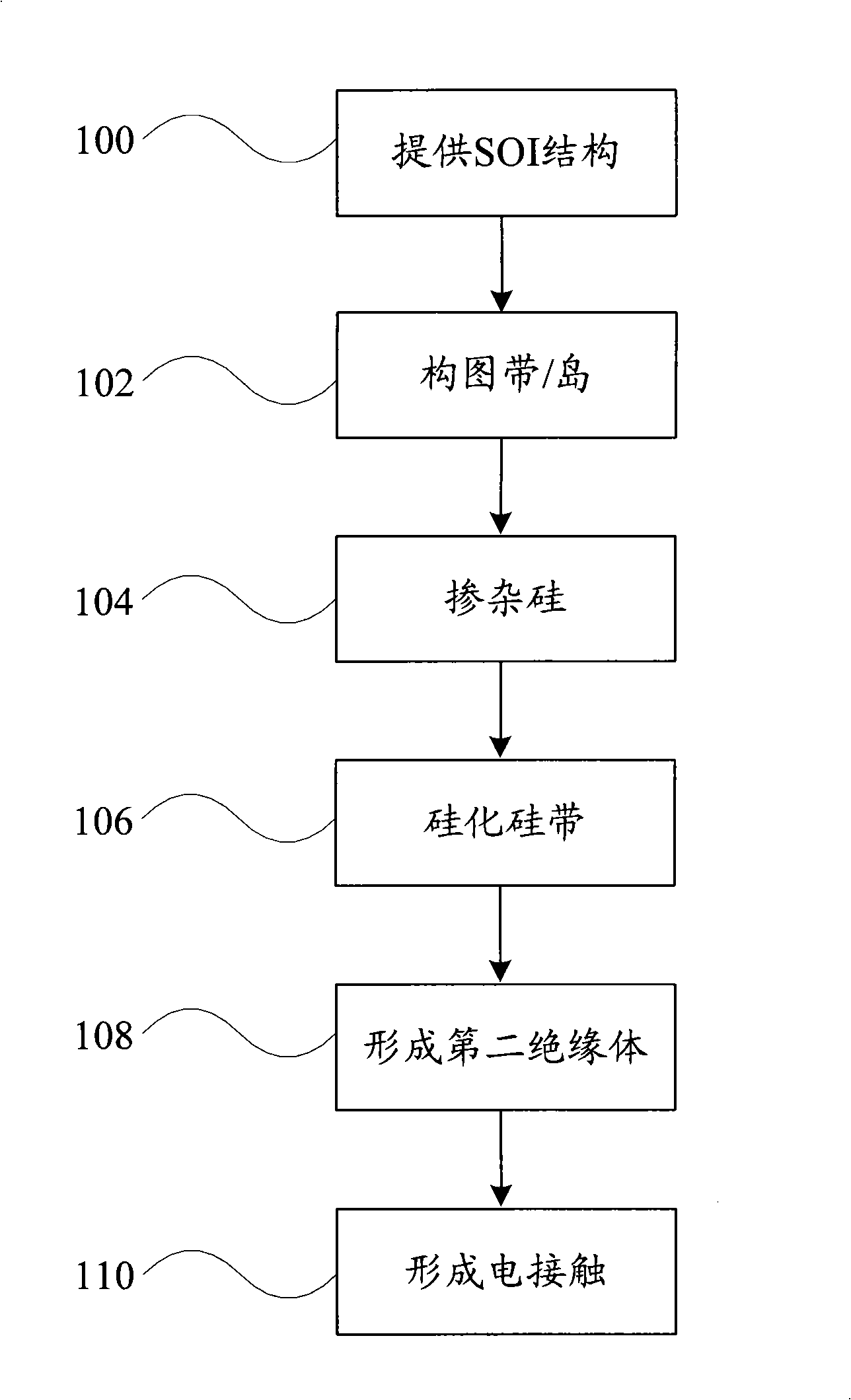

[0028] The present invention first provides a first embodiment of a method for forming a fuse, including: providing a semiconductor substrate; sequentially forming a first dielectric layer and a polysilicon layer on the semiconductor substrate, and the polysilicon layer adopts a polysilicon layer forming a transistor ; Forming at least two doped regions in the polysilicon layer, the conductivity types of the two adjacent doped regions are opposite; forming a silicide layer on the polysilicon layer with at least two doped regions; forming a silicide layer on the silicide layer second dielectric layer; form a via hole in the second dielectric layer, the via hole exposes the silicide layer; fill the via hole with a conductive material and be in contact with the silicide layer; fill the conductive material on the second dielectric layer The via locations of the material form the metal pads.

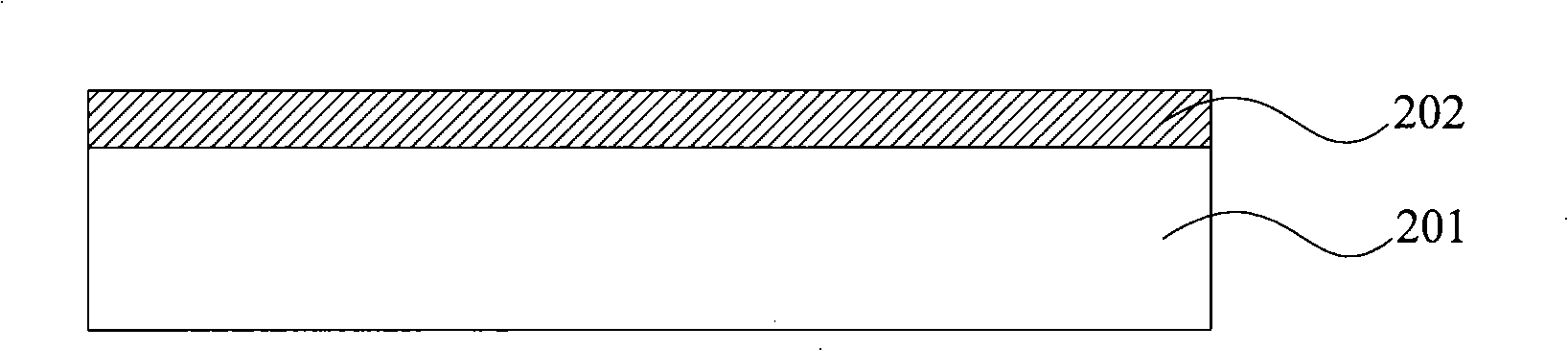

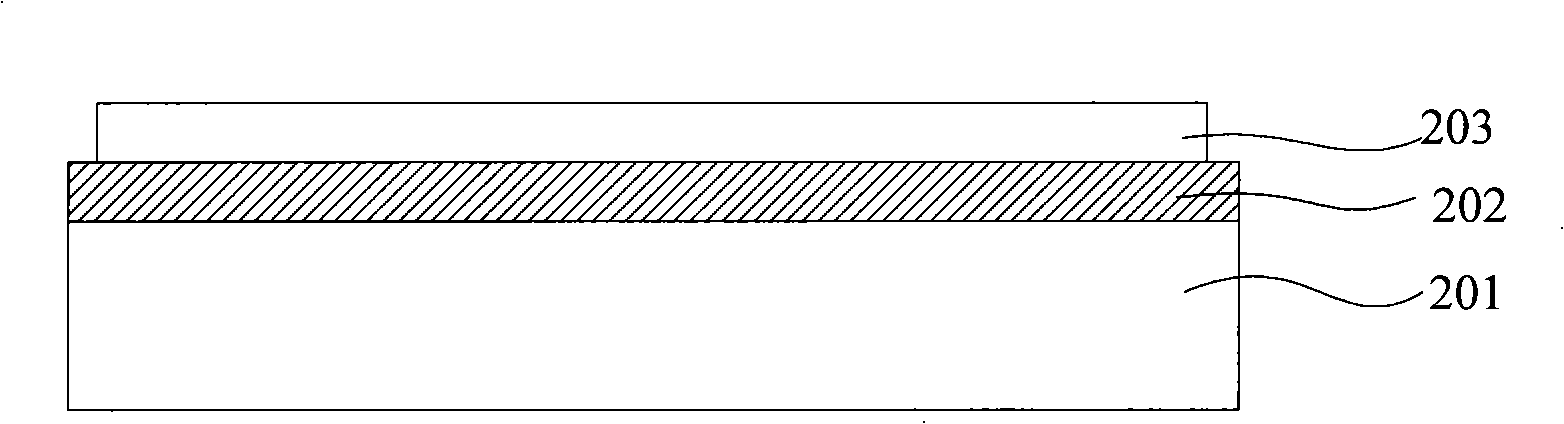

[0029] First refer to figure 2 , providing a semiconductor substrate 201, the semicondu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com