Photosensitive conductive aluminium paste and preparation method

A conductive silver paste and photosensitivity technology, applied in conductive coating composition and preparation thereof, photosensitive conductive silver paste and preparation field thereof, can solve the problem of high silver content in conductive silver paste, save precious metal silver and achieve stable performance , the effect of good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

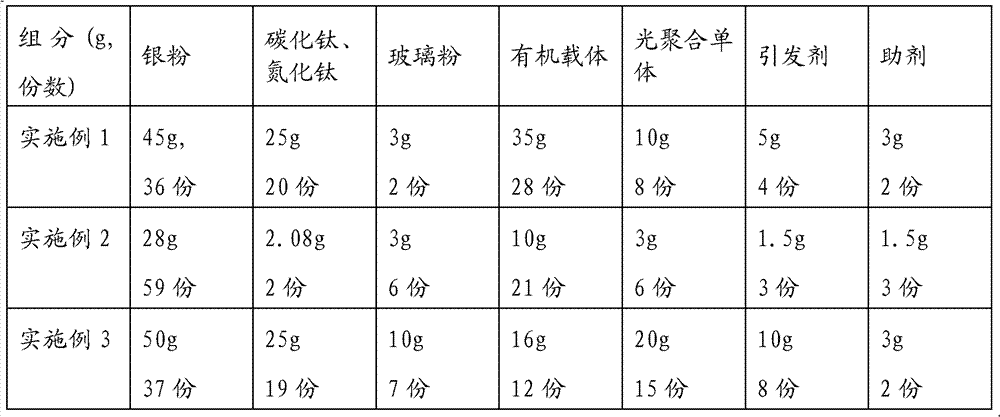

Embodiment 1

[0033] Get 15 grams of methacrylic acid-2-hydroxyethyl ester and methacrylic acid copolymer (weight-average molecular weight 30000), add to 20 grams of trimethylpentanediol isobutyrate In the medium, heat to 100°C, stir while heating until all solids are dissolved, cool to room temperature, and pass through a 40 micron filter to obtain a solution.

[0034] Get 45 grams of silver powder (particle diameter 1.5 micron, spherical), 25 grams of titanium nitride powder (particle diameter 1.0 micron), 3 grams of lead-free glass powder GF-01 ( Particle size 1.0-2.0 microns, softening point 425°C), 10 grams of photopolymerizable monomer TMPPOTA (trimethylolpropane propoxy triacrylate), 5 grams of photoinitiator (1-p-morpholine phenyl-2- Dimethylamino-2-benzyl-1-butanone), 1 g silane coupling agent 2-(3,4-epoxycyclohexyl) ethyl trimethoxysilane, 2 g plasticizer BYK-354 , in a yellow light environment, add it to the solution obtained above, stir evenly, and then use three-roll rolling...

Embodiment 2

[0036] Get 5 grams of methacrylic acid-2-hydroxyethyl ester and methacrylic acid copolymer (weight-average molecular weight 30000), add to 5 grams of trimethylpentanediol isobutyrate In the medium, heat to 100°C, stir while heating until all solids are dissolved, cool to room temperature, and pass through a 40 micron filter to obtain a solution.

[0037] Get 28 grams of silver powder (particle size 1.5 micron, spherical), 1 gram of titanium carbide powder (particle size 1.0 micron), 3 grams of lead-free glass powder GF-01 ( Particle size 1.0-2.0 microns, softening point 425°C), 3 grams of photopolymerizable monomer TMPPOTA (trimethylolpropane propoxy triacrylate), 1.5 grams of photoinitiator (1-p-morpholine phenyl-2- Dimethylamino-2-benzyl-1-butanone), 0.5 g silane coupling agent 2-(3,4-epoxycyclohexyl) ethyl trimethoxysilane, 1 g plasticizer BYK-354 , in a yellow light environment, add it to the solution obtained above, stir evenly, and then use three-roll rolling to obtai...

Embodiment 3

[0039] Get 10 grams of methacrylic acid-2-hydroxyethyl ester and methacrylic acid copolymer (weight-average molecular weight 30000), add to 6 grams of trimethylpentanediol isobutyrate In the medium, heat to 100°C, stir while heating until all the solids are dissolved, cool to room temperature, and pass through a 40 micron filter to obtain a solution.

[0040] Get 50 grams of silver powder (particle diameter 1.5 micron, spherical), 25 grams of titanium carbide powder (particle diameter 1.0 micron), 10 grams of lead-free glass powder GF-01 ( Particle size 1.0-2.0 microns, softening point 425°C), 20 grams of photopolymerizable monomer TMPPOTA (trimethylolpropane propoxy triacrylate), 10 grams of photoinitiator (1-p-morpholine phenyl-2- Dimethylamino-2-benzyl-1-butanone), 1 g silane coupling agent 2-(3,4-epoxycyclohexyl) ethyl trimethoxysilane, 2 g plasticizer BYK-354 , in a yellow light environment, add it to the solution obtained above, stir evenly, and then use three-roll rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com