Organic carrier composition for solar cell back surface field aluminium paste and preparation method thereof

A technology of solar cells and back-field aluminum paste, which is applied in the direction of cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., and can solve problems such as easy generation of fragments, high stress on silicon wafers, and deterioration of environmental pollution , achieve good dry film adhesion, reduce debris rate, and eliminate environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

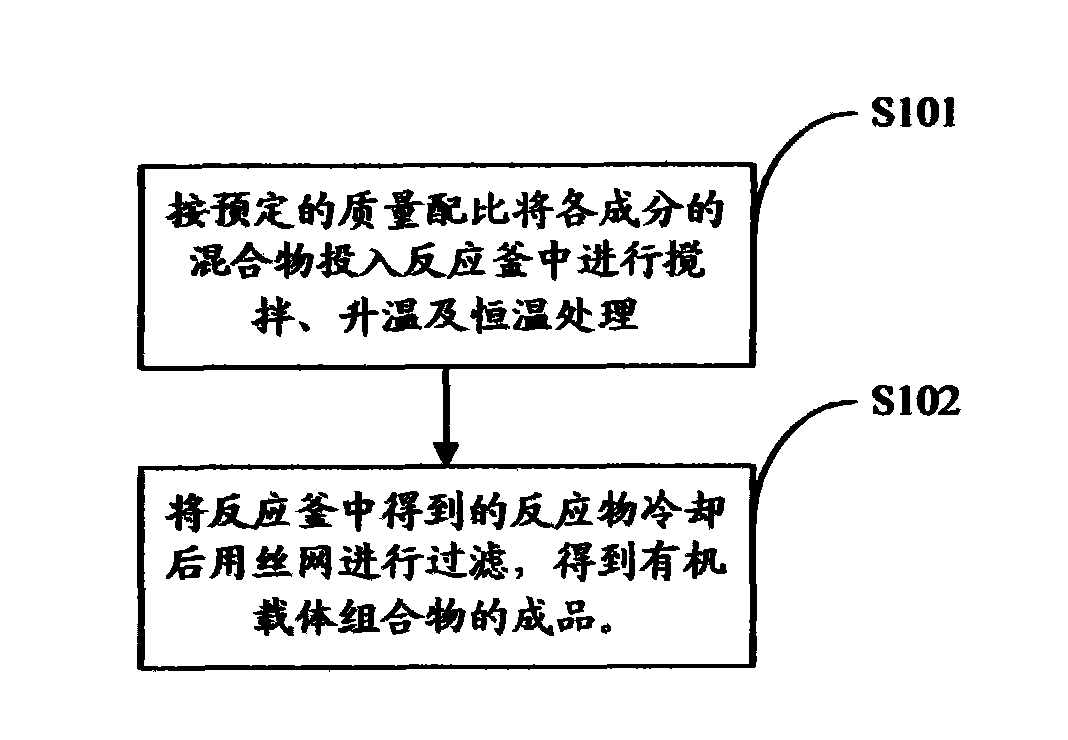

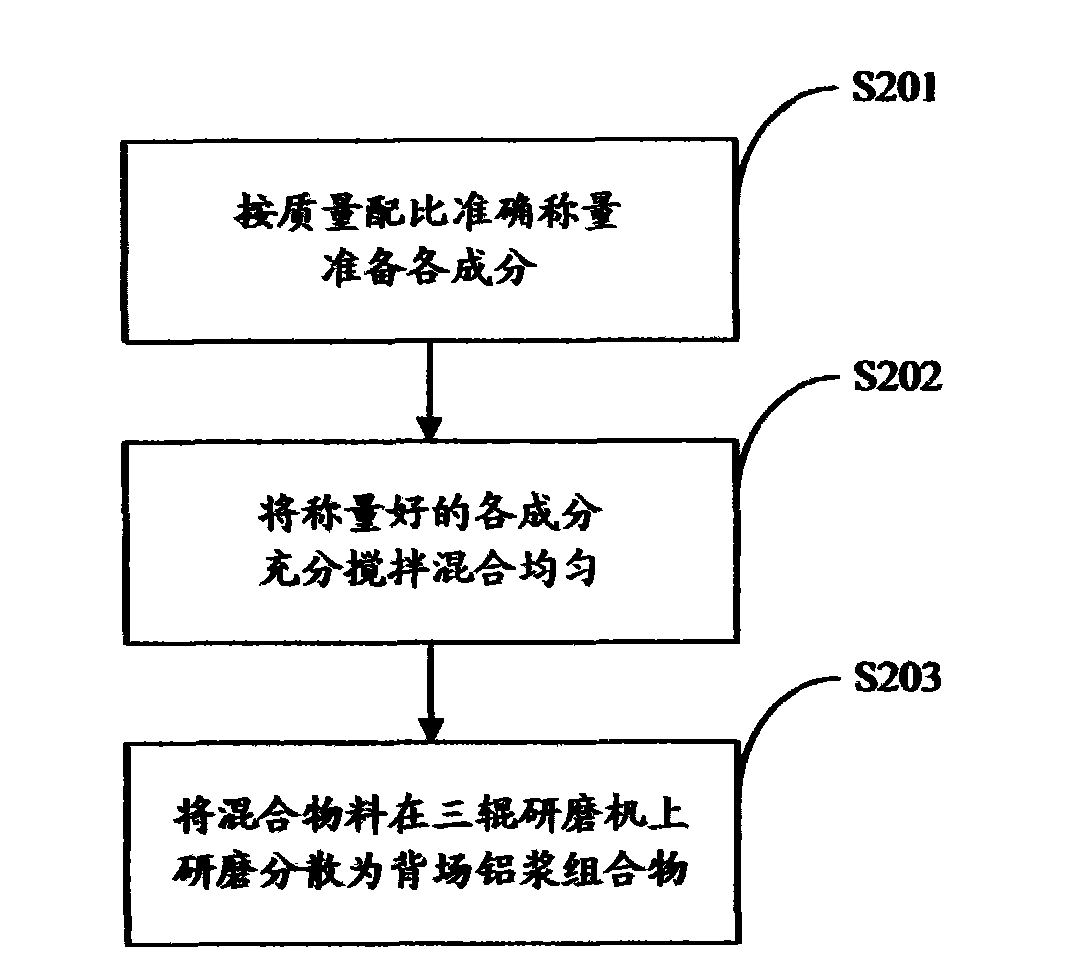

Method used

Image

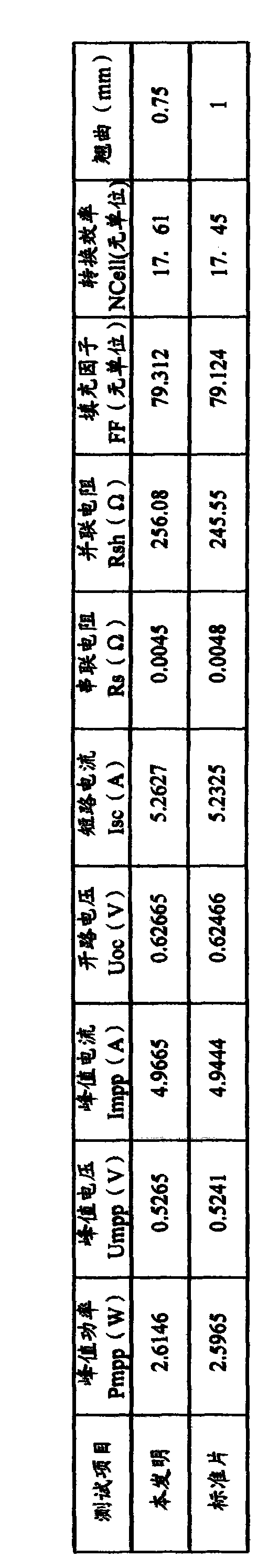

Examples

Embodiment Construction

[0032] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0033] Before describing the present invention, some basic principles and mechanisms involved in the present invention will be briefly introduced.

[0034] First, the general requirements for the selection of the organic carrier system for the back field aluminum paste of solar cells are as follows:

[0035] ·Chemically inert substances: no chemical reaction occurs when the carrier contacts with the aluminum powder particles, including heating;

[0036] Able to form a suspension: on the interface where the carrier and the aluminum powder particles are in contact with each other, the surface tension should be as small as possible to ensure good infiltration between the solid and the liquid; the carrier should have polar groups that stabilize the electrolyte, and should not There is an excessive amount of coagulant to avoid coagulation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com