Aluminium paste for silicon solar battery

A silicon solar cell, aluminum paste technology, applied in circuits, electrical components, conductive materials dispersed in non-conductive inorganic materials, etc., can solve problems such as poor adhesion, warpage of silicon wafers, and formation of aluminum beads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

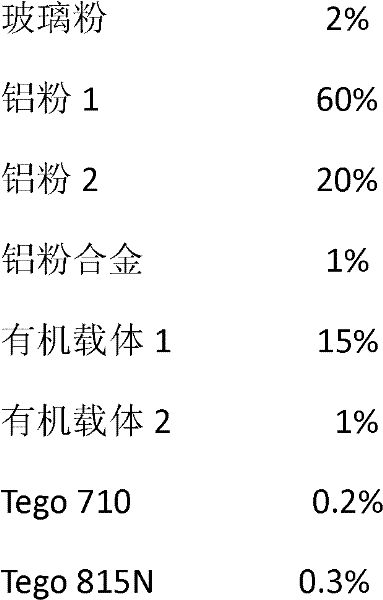

Embodiment 1

[0013] A silicon solar cell aluminum paste, composed of:

[0014]

[0015]

[0016] Wherein the organic carrier 1 is composed by mass: ethyl cellulose STD-45 12%, butyl carbitol 88%; the organic carrier 2 is composed by mass: rosin modified phenolic resin 15%, DBE 85%.

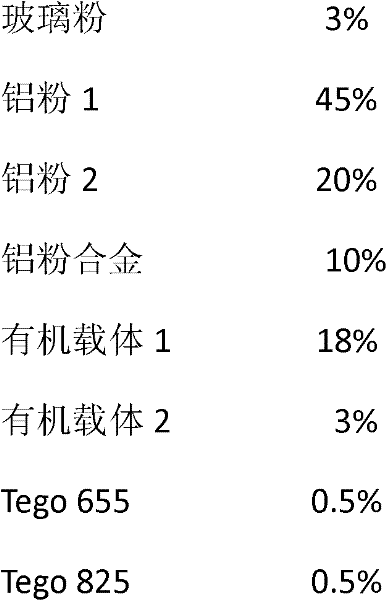

Embodiment 2

[0018] A silicon solar cell aluminum paste, composed of:

[0019]

[0020] The organic carrier 1 is composed by mass: ethyl cellulose STD-458%, butyl carbitol 92%; the organic carrier 2 is composed by mass: rosin modified phenolic resin 12%, DBE 88%.

Embodiment 3

[0022] A silicon solar cell aluminum paste, composed of:

[0023]

[0024]

[0025] The organic carrier 1 is composed by mass: ethyl cellulose STD-45 10%, butyl carbitol 90%; the organic carrier 2 is composed by mass: rosin modified phenolic resin 10%, DBE 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com