Relative humidity sensor of monolithic integrated porous silicon and preparation method of humidity sensor

A relative humidity, monolithic integration technology, applied in the direction of material capacitance, etc., can solve the problems of humidity sensor not specially designed dehumidification circuit, limited product application scope and market acceptance, complicated equipment structure, etc., to eliminate external interference, price, etc. Low cost, the effect of reducing the desorption time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] specific implementation

[0040] The structural features and method steps of the present invention will now be described in detail in conjunction with the accompanying drawings.

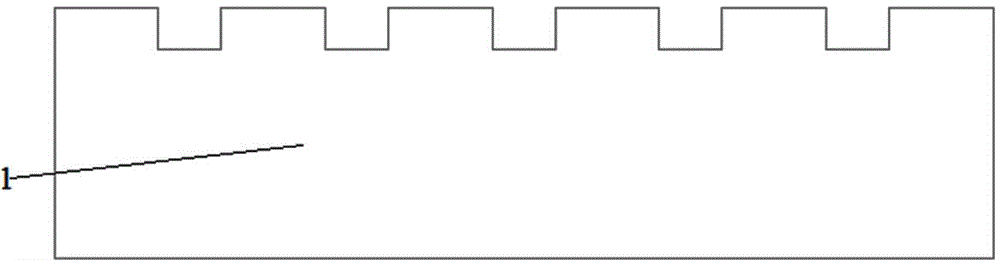

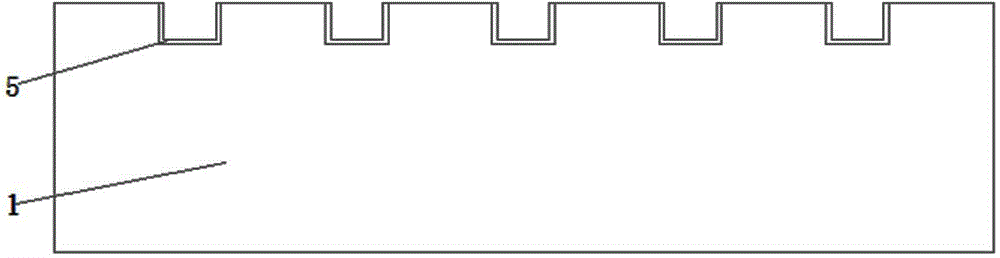

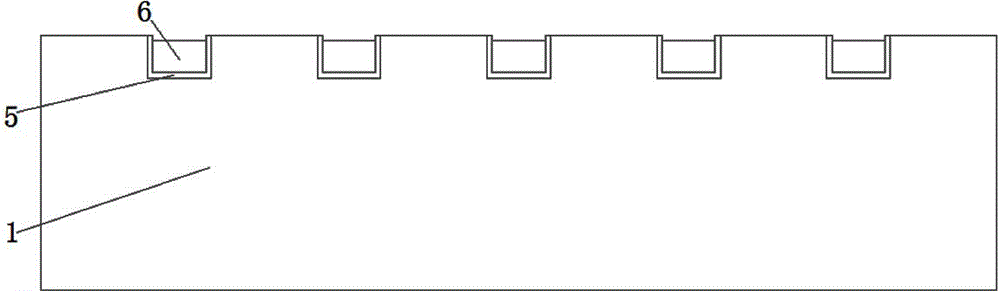

[0041] see figure 1 , a relative humidity sensor monolithically integrated porous silicon, comprising a substrate 1, the substrate 1 is a rectangular block. A pair of aluminum electrodes 6 are arranged on the top surface of the substrate 1, see figure 2 . The aluminum electrode 6 is comb-shaped, see image 3 . On the bottom surface of the aluminum electrode 6 and the side wall of the aluminum electrode 6, a layer of oxide isolation layer 5 is arranged, see figure 2 and image 3 . The top of the aluminum electrode 6 is provided with a passivation layer 4, see figure 2 . The comb teeth of the two aluminum electrodes 6 are interlaced, and the preferred solution is to arrange the comb teeth of the two aluminum electrodes 6 in an interdigitated equidistant manner. For details, see ima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com