Electrochemical reactor for simultaneously removing arsenic and fluorine pollutant in water and method

A reactor and electrochemical technology, which is applied in the field of integrated electrochemical reactors, can solve problems such as complex operation processes, and achieve the effects of inhibiting electrode passivation, effective removal and treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

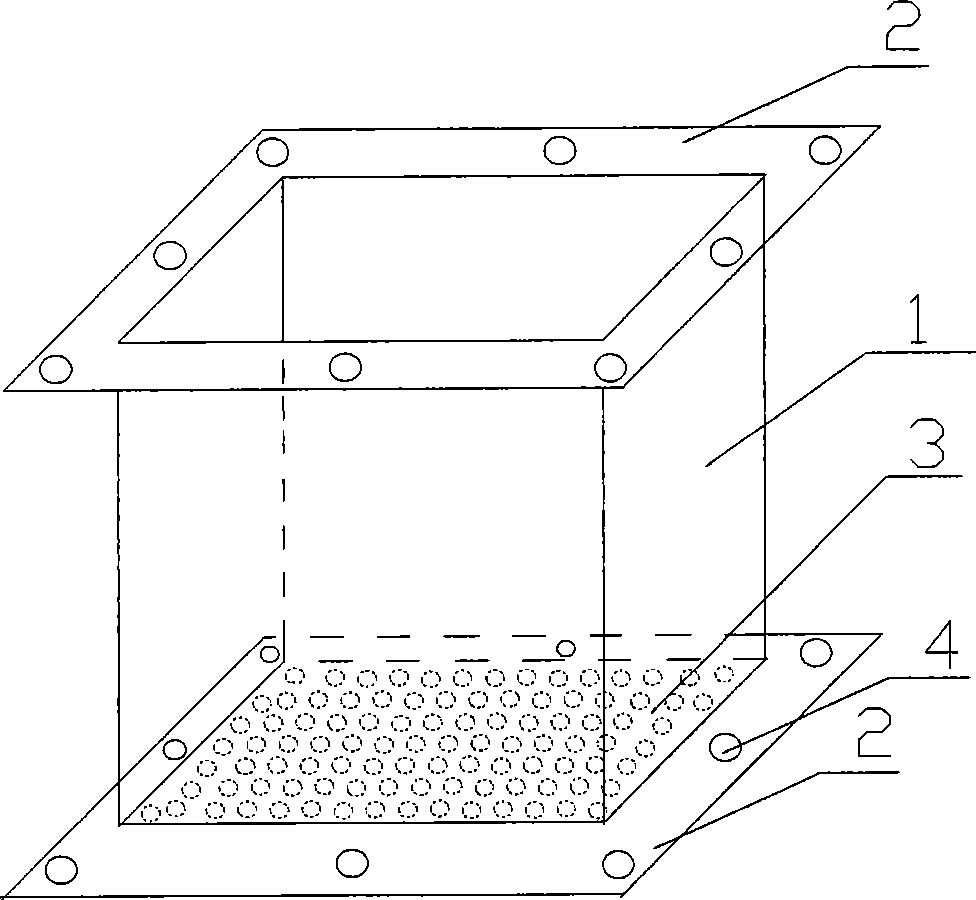

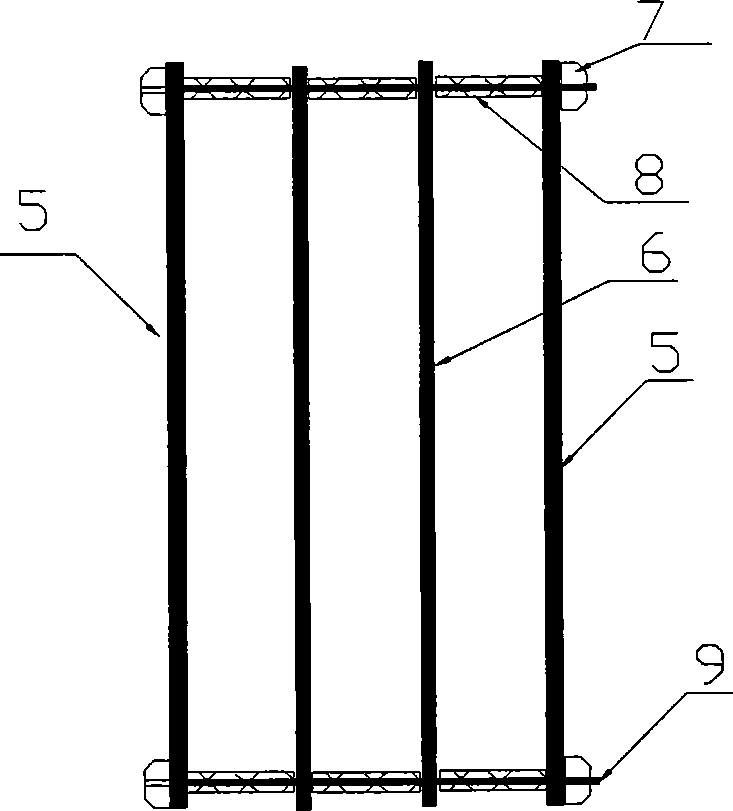

[0063] See figure 1 with 2 . The bottom in the electrochemical reactor 1 prepared by the organic glass material with the flange plate 2 at the top and the bottom and the water distribution plate 3 prepared by the organic glass material, there is an insulating pad on the top of the water distribution plate 3 1 piece of iron plate electrode and 1 piece of aluminum plate electrode 6 and 2 pieces of shape-stable electrodes 5 fixed on the insulating rod 9 with piece 8 and nut 7, there is a bolt port 4 on the flange plate, through which the flange plate 2 can be connected again Chemical Reactor 1.

[0064] The shape-stable electrodes are intermittently alternately switching the positive and negative poles of the power supply as the anode and cathode, or as the cathode and the anode, and are installed in parallel in the electrochemical reactor 1; the two shape-stable electrodes are respectively connected to the external circuit of the reactor. The two external circuit wires are re...

Embodiment 2

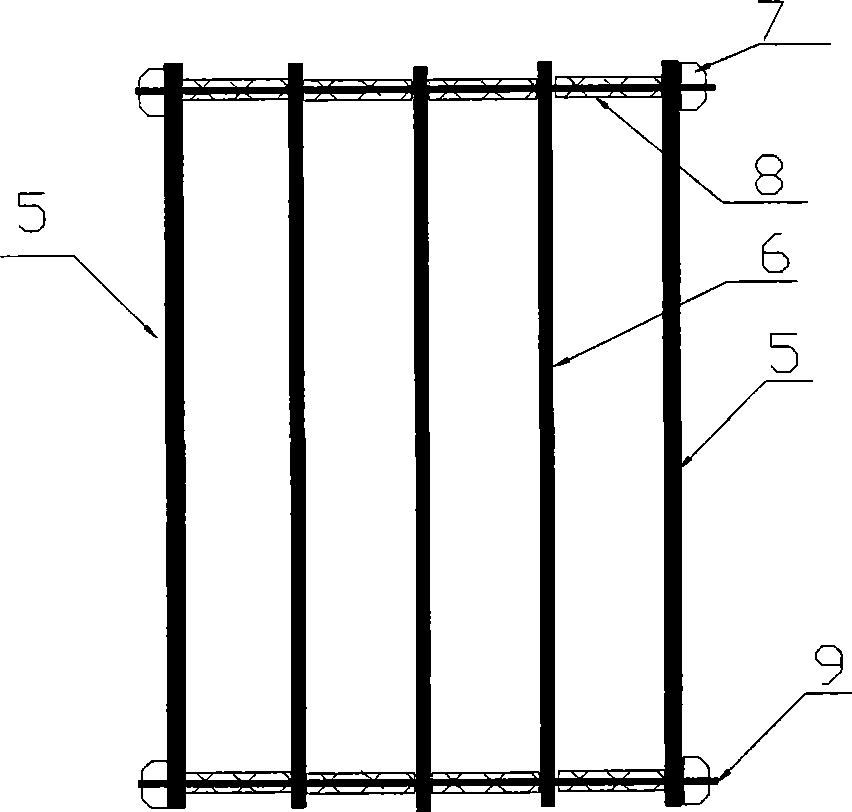

[0073] See figure 1 with 3 . There is a water distribution plate 3 made of organic glass material at the bottom of the electrochemical reactor 1 made of stainless steel with flanges 2 on the top and bottom, and an insulating gasket 8 is arranged above the water distribution plate 3 2 iron plate electrodes, 1 aluminum plate electrode 6 and 2 shape-stable electrodes 5 fixed on the insulating rod 9 with nut 7; there is a bolt port 4 on the flange plate, and the electrochemical reaction can be connected through the flange plate 2 Device 1. The plate connection mode is shape stable electrode-iron plate-aluminum plate-iron plate-shape stable electrode. Wires connected to the external circuit of the electrochemical reactor are respectively connected to the outermost shape-stable electrodes on both sides, and the two external circuit wires are respectively connected to the positive pole and the negative pole of the DC power supply.

[0074] A water inlet is opened on the side wall...

Embodiment 3

[0080] Seefigure 1 with 3 . There is a water distribution plate 3 made of organic glass material at the bottom of the electrochemical reactor 1 made of stainless steel with flanges 2 on the top and bottom, and an insulating gasket 8 is arranged above the water distribution plate 3 2 iron plate electrodes, 1 aluminum plate electrode 6 and 2 shape-stable electrodes fixed on the insulating rod 9 with nut 7; there is a bolt port 4 on the flange plate, and the electrochemical reactor can be connected through the flange plate 2 1. The electrode connection method is shape-stable electrode-iron plate-iron plate-aluminum plate-shape-stable electrode, and the distance between the plates is 3 cm.

[0081] The shape-stable electrodes are intermittently alternately switching the positive and negative electrodes of the power supply as the anode and the cathode, or as the cathode and the anode, and are installed in parallel in the reactor 1; the shape-stable electrodes are connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com