Al/Al2O3/BaTiO3 composite film super capacitor and preparation method thereof

A technology of supercapacitors and composite films, which is applied in the manufacture of hybrid/electric double-layer capacitors, electrodes of hybrid capacitors, electrolytic capacitors, etc. Small dielectric constant and other problems, to achieve the effect of improving dielectric properties and capacity properties, improving capacity and good dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

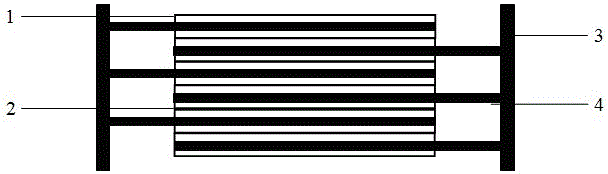

[0036] This example is used to illustrate the Al / Al 2 o 3 / BaTiO 3 Preparation method of composite film capacitor and its electrochemical performance.

[0037] (1) Aluminum sheet electrode surface treatment

[0038] Cut the aluminum sheet to a size of 3×3cm, and apply appropriate pressure with a tablet press to make the aluminum sheet flat. Ultrasonic cleaning with anhydrous ethanol solution for 10 minutes to remove the grease on the surface of the aluminum sheet, then treatment with 0.1mol / L lye to remove the natural oxide film, and finally chemical polishing with mixed acid (the volume ratio of oxalic acid and phosphoric acid is 1:1) to obtain smooth surface. Then, the surface of the aluminum electrode was treated with triethanolamine treatment solution, the concentration of the treatment solution was 1.5 mol / L, the temperature of the water bath was 75 °C, and the treatment time was 9 min.

[0039] (2) Calcination of barium titanate and pulling coating of barium titanat...

Embodiment 2

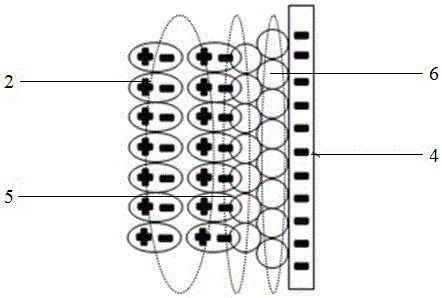

[0048] Carry out charge and discharge tests under different high voltages on 5 superimposed capacitors. The mass of the single-sided dielectric layer is 50 mg, that is, the single layer is 50 mg. After 5 superimposed capacitors are equivalent to four capacitors connected in parallel, the total dielectric layer The mass is 0.4g. Under the high voltage of 100V, 200V, 300V, and the current of 20mA, the constant current charge and discharge are carried out. The discharge capacities under the three voltages of 100V, 200V, and 300V are: 3.04×10 -6 Ah, 8.12×10 -6 Ah, 1.22×10 -5 Ah. The discharge time is respectively: 1.07s, 1.45s, 2.18s.

[0049] It can be obtained from Q = I × t = C × U that:

[0050] At 100V, capacity density = Q / U = (3.04×10 -6 Ah · 3600s) / (100V · 0.4g) = 0.92 × 10 -4 F / g. Capacity density: 0.76 Wh / Kg, power density: 2557 W / Kg. Then the capacitance of a single-sided dielectric layer can reach: C = 0.46 × 10 -5 F.

[0051] At 200V, capacity den...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

| Capacity density | aaaaa | aaaaa |

| Capacity density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com