Method for preparing flexible Cu-In-Ga-Se thin film solar cell

A thin film solar cell, copper indium gallium selenide technology, applied in circuits, photovoltaic power generation, electrical components and other directions, can solve the problems of battery performance degradation, affecting the crystalline quality and optoelectronic properties of the CIGS light absorption layer, etc. Crystal quality and optoelectronic properties, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

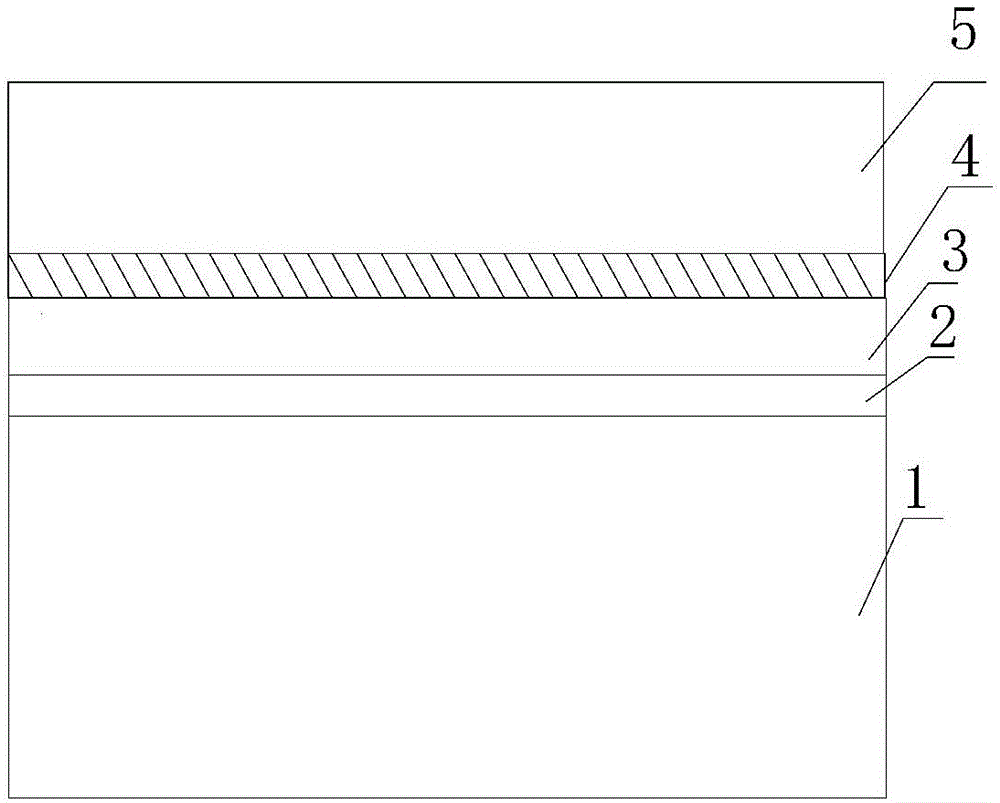

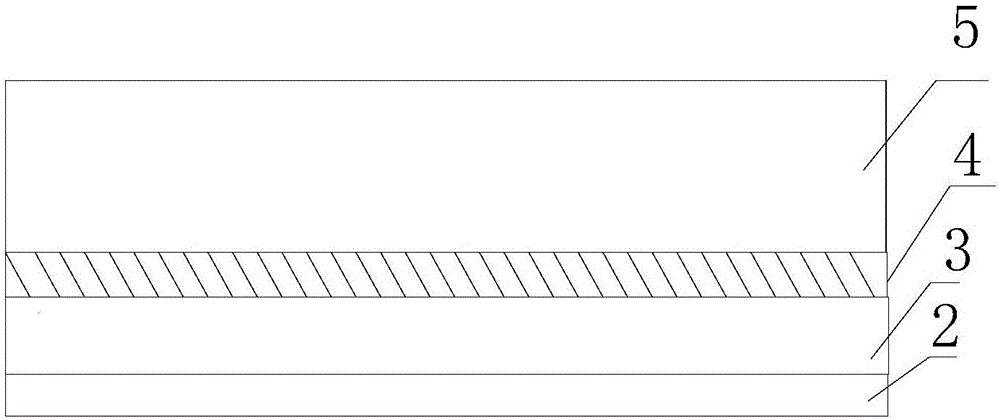

[0038] A method for preparing a flexible copper indium gallium selenide thin film solar cell, comprising:

[0039]Step 1: Using a soda line glass substrate (soda line glass) with a thickness of about 1.5mm-2mm, first deposit a Mo film with a thickness of 0.5μm-1μm by magnetron sputtering process as the positive electrode of the battery, and then prepare it by co-evaporation three-step method For CIGS light absorbing layer, the deposition temperature is about 530°C-570°C. During this process, the Na atoms in the glass substrate diffuse into the CIGS absorbing layer to form a soda-lime glass substrate 1, which has a significant effect on improving its electrical properties (as confirmed by previous literature), and solves the problem of flexible substrates. It does not contain alkali metal elements and requires an additional doping process.

[0040] Step 2: Coat a layer of paraffin wax on the surface of the CIGS light absorbing layer, and cover the edges and sides of the absorb...

Embodiment 1

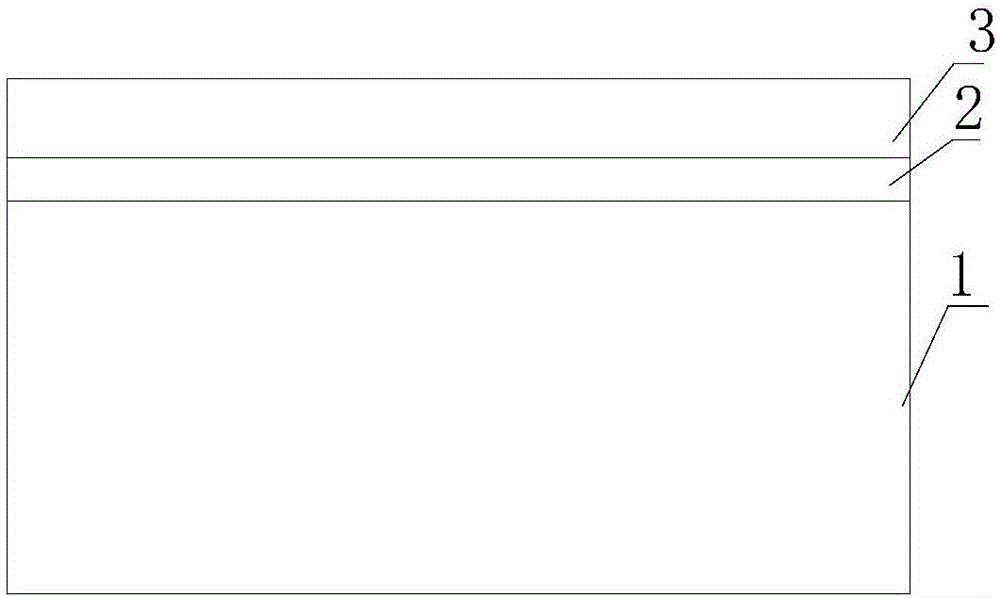

[0045] Embodiment 1, see attached figure 1

[0046] The method for preparing a CIGS light-absorbing layer solar cell on a flexible plastic substrate described in this patent, the process is as follows:

[0047] 1) The glass substrate 1 is cleaned. A soda line glass substrate (soda line glass) with a thickness of about 1.5 mm to 2 mm was soaked in acetone and cleaned ultrasonically for 40 min. After rinsing with deionized water, immerse in ethanol for ultrasonic cleaning for 20 minutes, and then rinse repeatedly with deionized water.

[0048] 2) Prepare the positive electrode 2 of the battery. A Mo film with a thickness of 0.5 μm to 1 μm is deposited on a glass substrate by using a DC magnetron sputtering process as the positive electrode of the battery, that is, the Mo electrode layer 2 . The sputtering process uses a background vacuum of 1×10 -3 Pa, by adjusting the flow rate of Ar gas, two layers of Mo films are deposited successively under the conditions of pressure of...

Embodiment 2

[0054] Embodiment 2, see attached figure 1

[0055] The method for preparing a CIGS light-absorbing layer solar cell on a flexible metal substrate described in this patent, the process is as follows:

[0056] 1) The glass substrate 1 is cleaned. A soda line glass substrate (soda line glass) with a thickness of about 1.5 mm to 2 mm was soaked in acetone and cleaned ultrasonically for 40 min. After rinsing with deionized water, immerse in ethanol for ultrasonic cleaning for 20 minutes, and then rinse repeatedly with deionized water.

[0057] 2) Prepare battery positive electrode-2. A Mo film with a thickness of 0.5 μm to 1 μm is deposited on a glass substrate by a DC magnetron sputtering process as the positive electrode of the battery. The sputtering process uses a background vacuum of 1×10 -3 Pa, by adjusting the flow rate of Ar gas, two layers of Mo films are deposited successively under the conditions of pressure of 1-5Pa and pressure of 0.01-0.5Pa, and the ratio of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com