Optimized piezo driven micro spraying device and fabricating method

A technology of piezoelectric drive and processing method, which is applied in the field of medical equipment, can solve the problems of small flow rate of micro-spray, and achieve the effect of increasing flow rate, avoiding water film problem, and uniform distribution of droplet spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

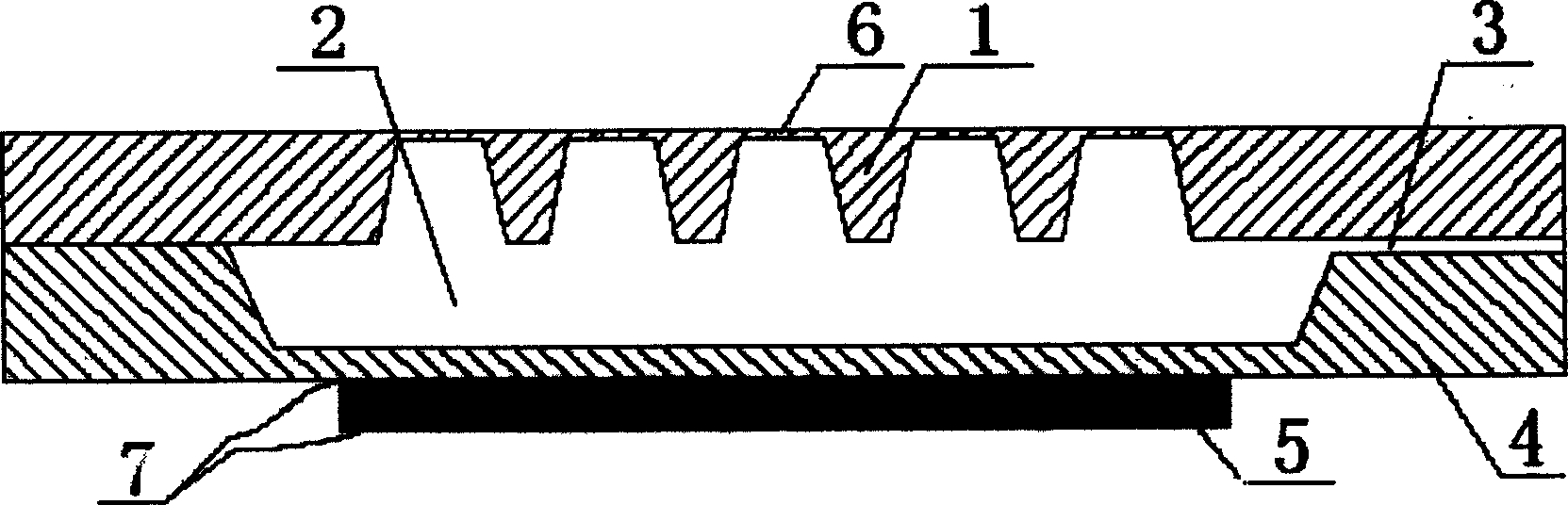

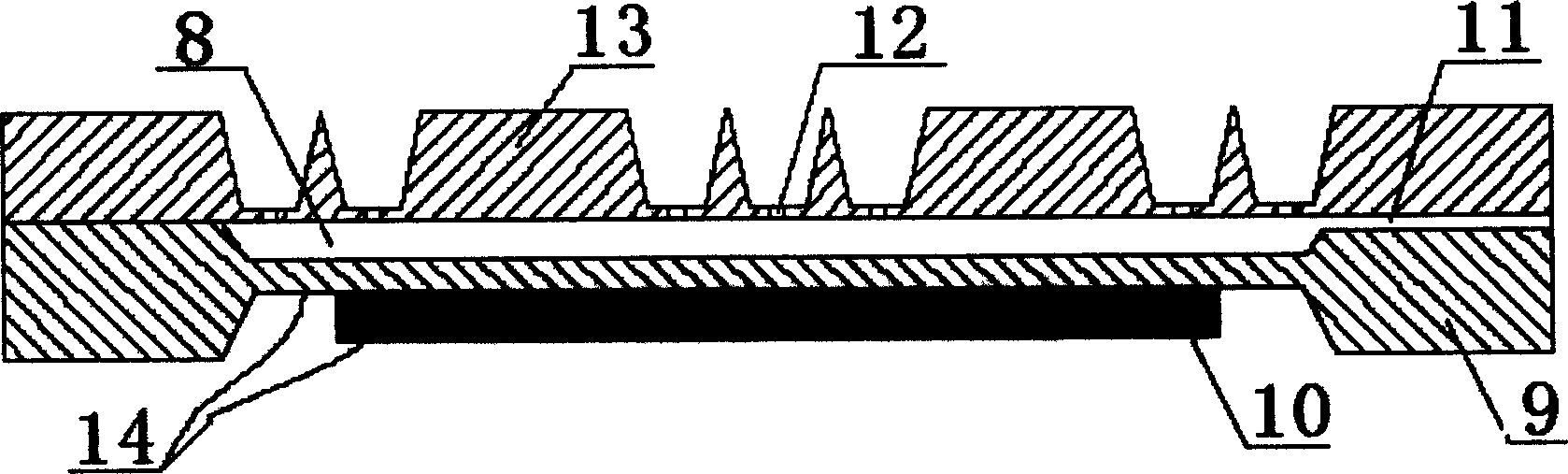

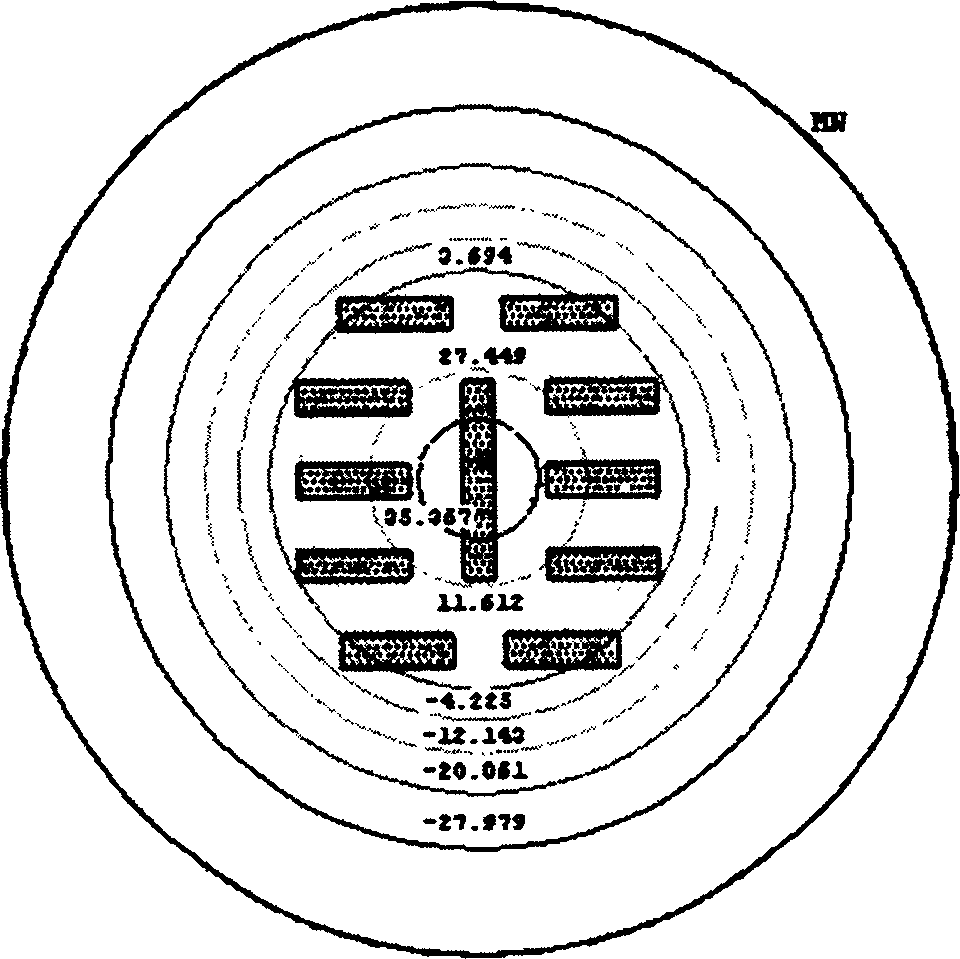

[0029] According to the requirements of the application and previous relevant research results, the embodiment of the optimized piezoelectric-driven array micro-spray structure designed by the present invention is as follows image 3 shown. The device is mainly composed of an orifice membrane 13 , an elastic cavity membrane 9 and a piezoelectric sheet 10 . The orifice film 13 first uses the ICP process to etch the micro-nozzle array 12, and then uses the bulk silicon process to etch the groove structure on the silicon wafer, and makes the micro-nozzle become a through hole, and the diameter of the micro-nozzle is controlled at 3 Between ~30μm, the length is 30μm, and the number of nozzle holes is 4000. The elastic cavity membrane 9 is the remaining part after the circular grooves with a diameter of 10 mm, a depth of 100 μm and a depth of 200 μm are respectively etched on the upper and lower surfaces of the silicon wafer by the bulk silicon process, and the thickness is 100 μm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com