Cutting fluid atomizing spray head device for CMQL cutting

A technology of atomizing nozzles and cutting processing, applied in the direction of spraying devices, spraying devices, etc., can solve the problems of cutting fluid retention and waste, uneven spraying area, etc., achieve the effects of small environmental pollution, simple and safe operation, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

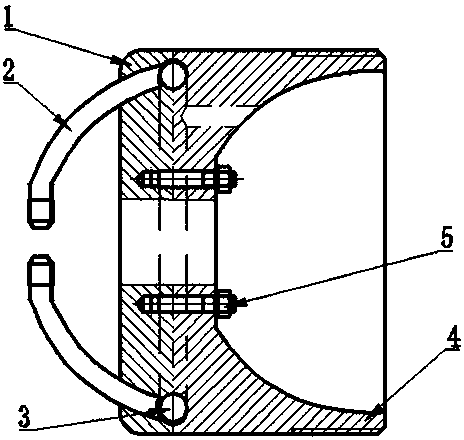

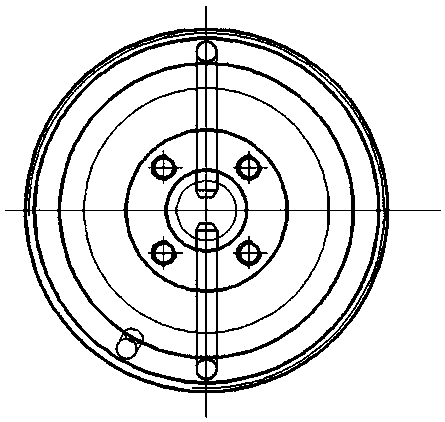

[0013] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure in a schematic way, so they only show the components related to the present invention.

[0014] Such as Figure 5 Shown is a schematic diagram of the working principle of the nozzle, showing the confluence of gas and liquid at the nozzle.

[0015] The working principle of the present invention is: the cutting fluid passes through the cutting fluid inlet pipe, and the cutting fluid is delivered to (3) the annular bag, and the cutting fluid delivery channel is connected through the two gaps of (3) the annular bag, and the cutting fluid flows to ( 2) Needle-shaped liquid spray head, due to (2) the design of the needle-shaped liquid spray head itself, the outlet is only 0.8mm in radius, and the needle outlet has a smaller filter to ensure the use of the smallest trace. The outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com