Dishwasher with integrated spray channels

A dishwashing machine and jet channel technology, applied in dishwashing machine/washing machine, household utensils, cleaning equipment, etc., can solve problems such as the inability to guarantee the uniform cleaning effect of washed items, and avoid wear and interference, large Degree of freedom, uniform spray distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

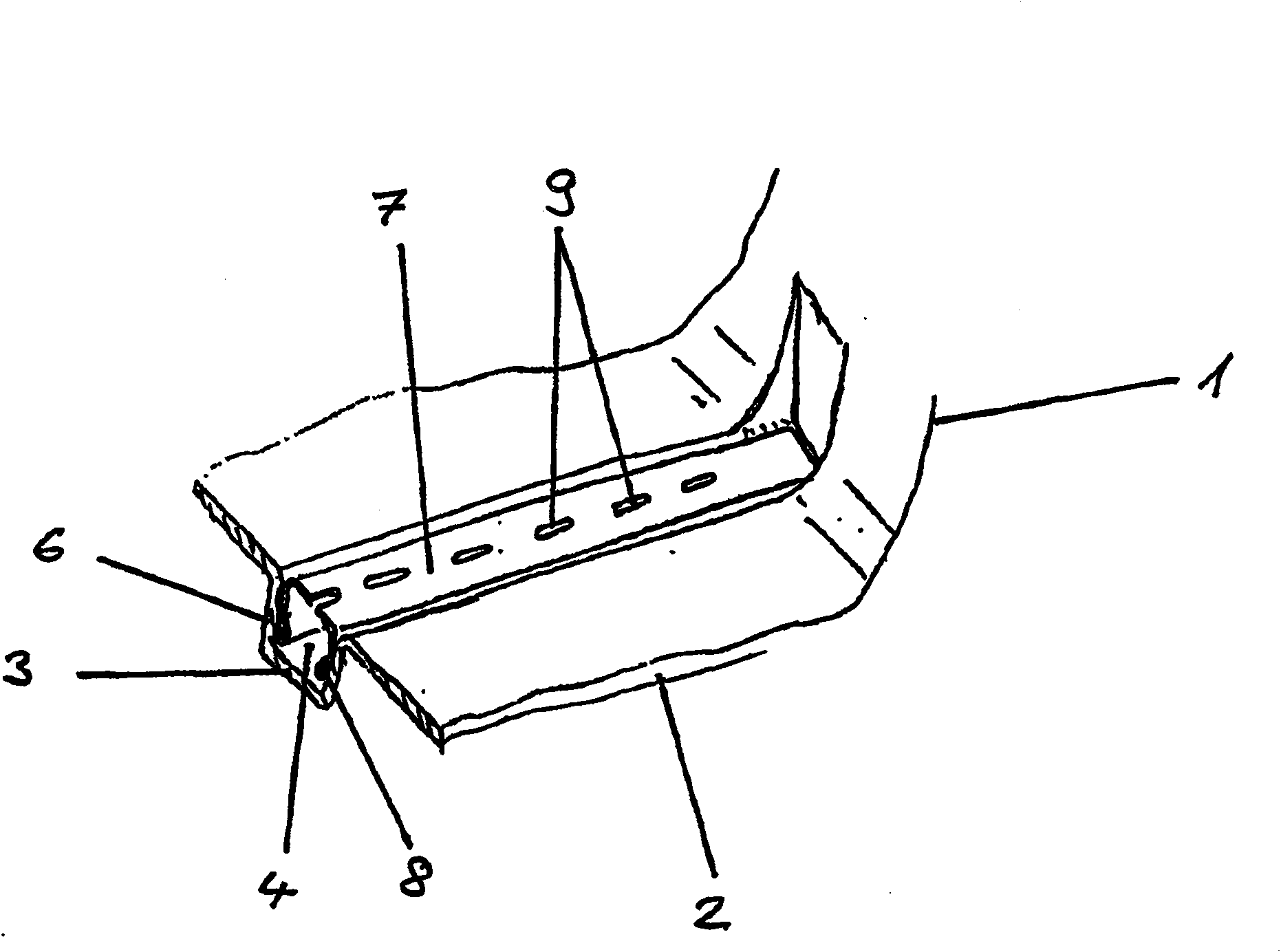

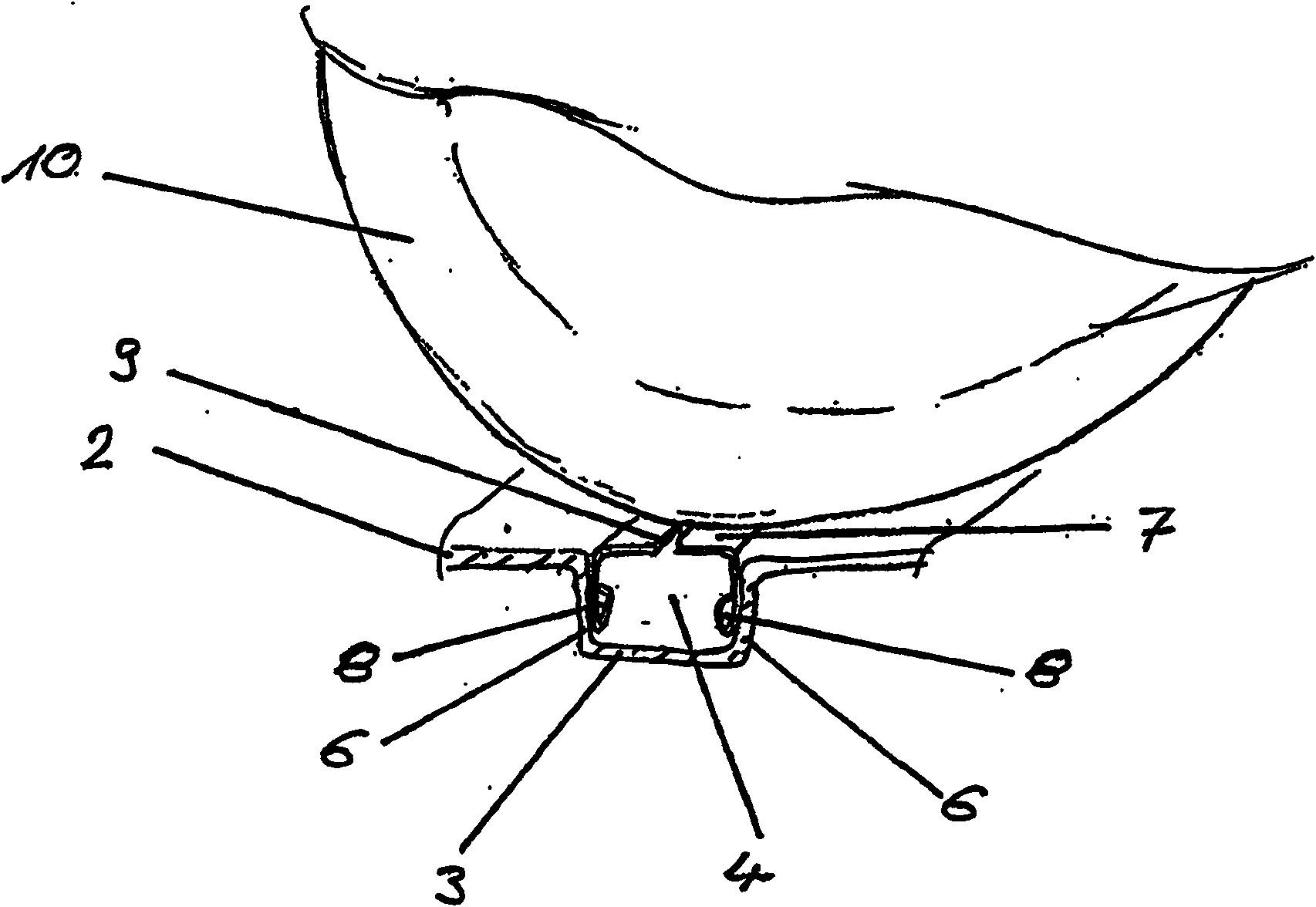

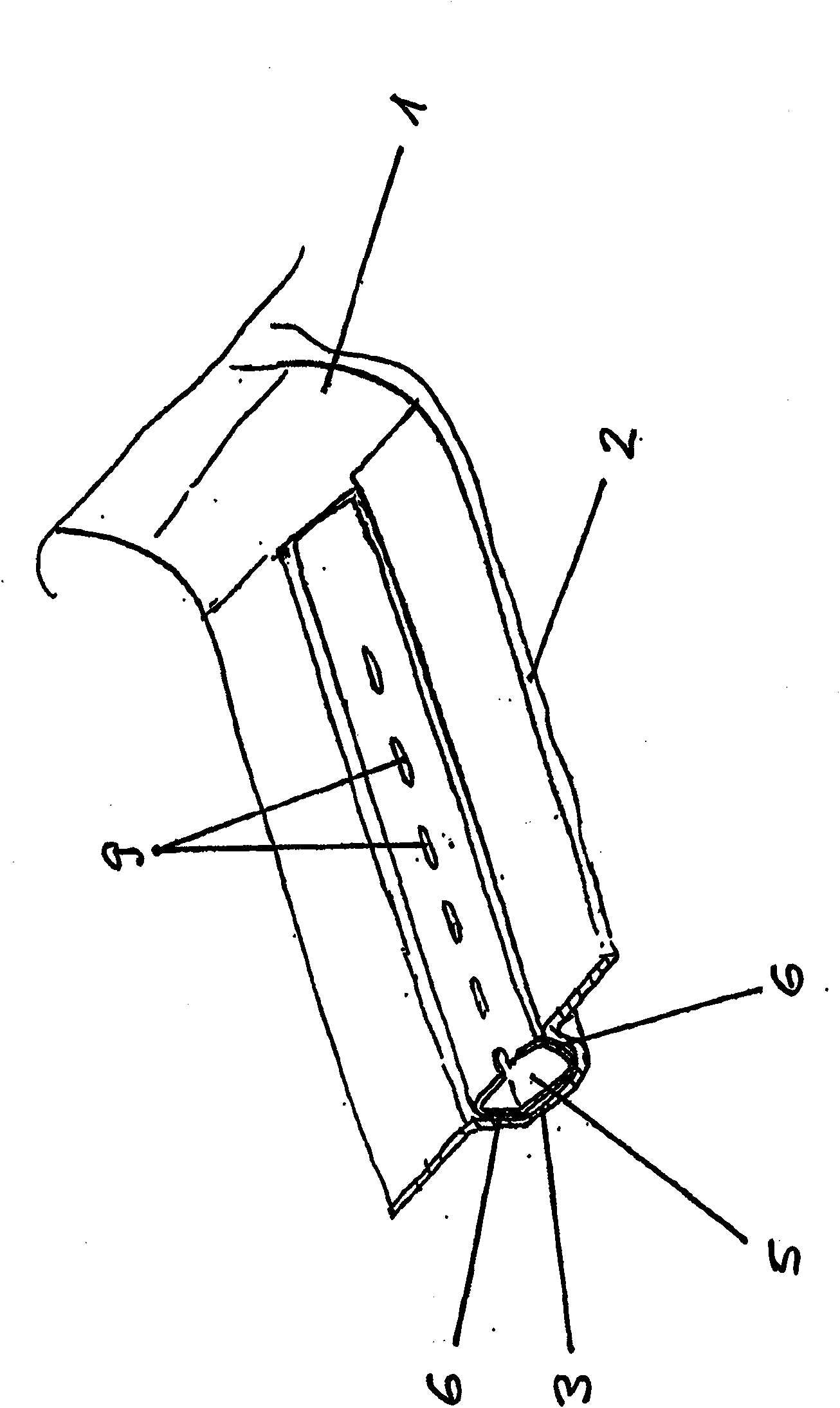

[0027] figure 1A part of a washing container 1 of a dishwasher according to the invention with a spray device according to a first embodiment is shown. A part of the floor of the washing container 1 is shown in sectional view, in which a groove-shaped recess 3 is arranged. Arranged on the recess 3 in the base 2 of the washing container 1 is a removable cover 7 which covers the recess 3 over its entire length. The recess 3 thus cooperates with the cover plate 7 to form a spray channel 4 , which is supplied with washing liquid by the circulation pump during operation. An opening 9 is provided in the cover plate 7 for the exit of washing liquid from the spray channel 4 into the interior of the washing container 1 .

[0028] In the first embodiment, the cover plate 7 has a symmetrical, substantially U-shaped cross section, wherein the two free ends of the U-shaped cross section are formed by arms 8 . The cover 7 is made of an elastic material, so that the arms 8 can be bent tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com