Compound corrosion inhibitor of alkaline electrolyte of alkaline aluminium battery, electrolyte and preparation method of compound corrosion inhibitor

A composite corrosion inhibitor and electrolyte technology, applied in the direction of alkaline batteries, etc., can solve the problem that the corrosion inhibitor is difficult to meet the requirements of wide application and cannot be taken into account, and achieves improved service life and work efficiency, low cost, Implement simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] According to the concentration of sodium stannate 0.015mol / L, indium hydroxide 0.005mol / L, sodium citrate 0.03mol / L, calcium oxide 0.003mol / L, zinc oxide 0.02mol / L in the electrolyte, the required mass Sodium stannate, indium hydroxide, sodium citrate, calcium oxide, and zinc oxide are ground separately, and then the solid powders are mixed evenly. Then take 1.0L of 6mol / L NaOH solution, add the mixed solid powder into the lye in 5 times, stir to dissolve, and let it stand for 7 minutes. Get raw material by N-hydroxypropyltrimethylammonium chloride chitosan (GTCC): 0.045%wt; Sodium dodecylbenzenesulfonate: 0.4%wt by weight percentage, raw material is added to dissolve mixed solid powder In the lye, stir and mix to obtain the alkaline aluminum battery electrolyte containing the composite corrosion inhibitor.

Embodiment 2

[0019] According to the concentration of sodium stannate 0.02mol / L, indium hydroxide 0.005mol / L, sodium citrate 0.03mol / L, calcium oxide 0.004mol / L, zinc oxide 0.02mol / L in the electrolyte, the required mass Sodium stannate, indium hydroxide, sodium citrate, calcium oxide, and zinc oxide are ground separately, and then the solid powders are mixed evenly. Take 1.0L of 6mol / L NaOH solution, add the mixed solid powder into the lye in 6 times, stir to dissolve it, and let it stand for 6 minutes. Press N-hydroxypropyl trioctyl ammonium chloride chitosan (GOCC): 0.05%wt; Sodium dodecylbenzenesulfonate: 0.4%wt weight percentage gets raw material, raw material is joined respectively in dissolving mixed solid Stir and mix evenly in the powdered lye to obtain the alkaline aluminum battery electrolyte containing the composite corrosion inhibitor.

Embodiment 3

[0021] According to the concentration of sodium stannate 0.015mol / L, indium hydroxide 0.005mol / L, sodium citrate 0.04mol / L, calcium oxide 0.004mol / L, zinc oxide 0.03mol / L in the electrolyte, the required mass Sodium stannate, indium hydroxide, sodium citrate, calcium oxide, and zinc oxide are ground separately, and then the solid powders are mixed evenly. Then take 1.0L of 6mol / L NaOH solution, add the mixed solid powder into the lye in 7 times, stir to dissolve, and let it stand for 8 minutes. According to O-carboxymethyl-N-(3-octadecyloxy-2-carboxymethoxypropyl) chitosan (CAPCTS): 0.045%wt; sodium dodecylbenzenesulfonate: 0.4%wt The weight percent of the raw materials is taken, and the raw materials are respectively added to the lye solution in which the mixed solid powder is dissolved, stirred and mixed evenly, and the alkaline aluminum battery electrolyte containing the composite corrosion inhibitor is obtained.

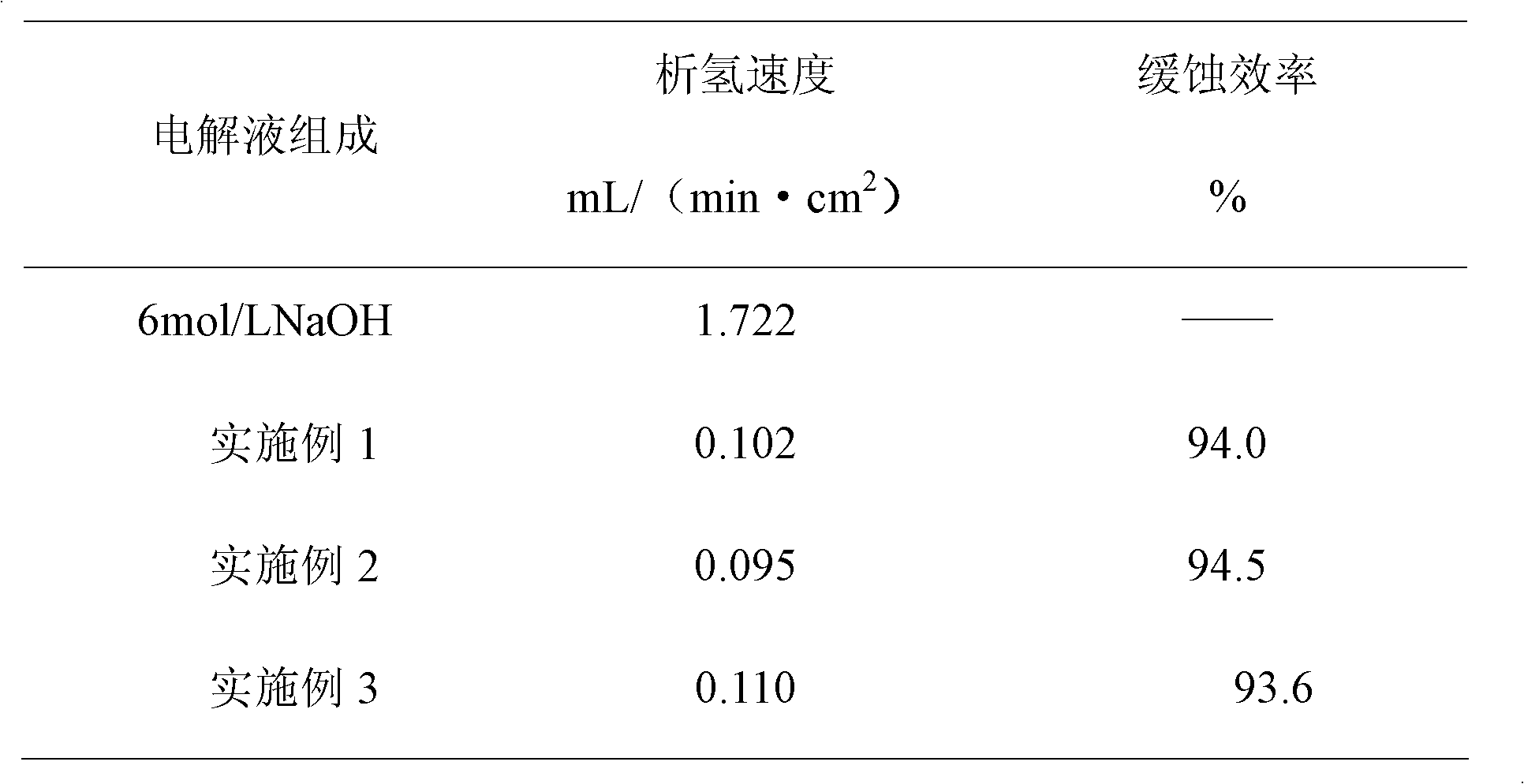

[0022] Attached table: Hydrogen evolution rate of Al alloy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com