Chip having high sensitivity for silicon micro-capacitor microphone and preparation method thereof

A condenser microphone and high-sensitivity technology, applied in the direction of sensors, electrical components, etc., can solve the problems of microphone sensitivity drop, aging cracking, etc., and achieve the effects of avoiding aging cracking, reducing corrosion, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

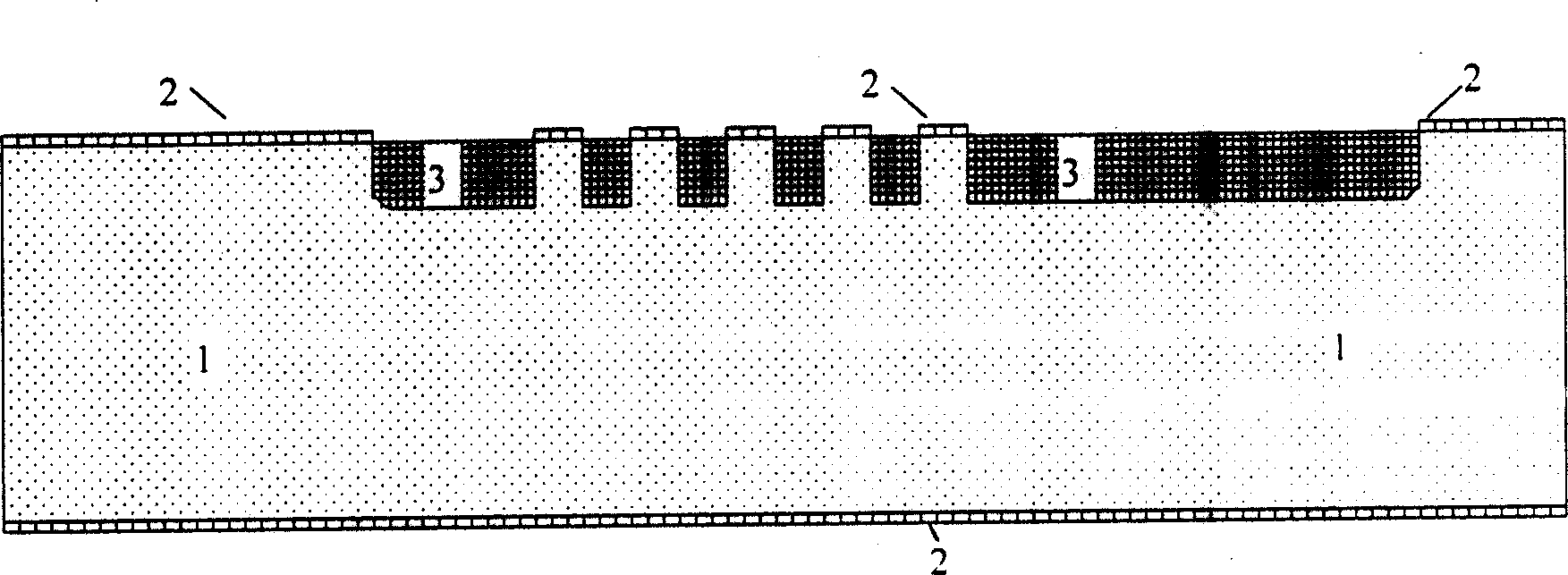

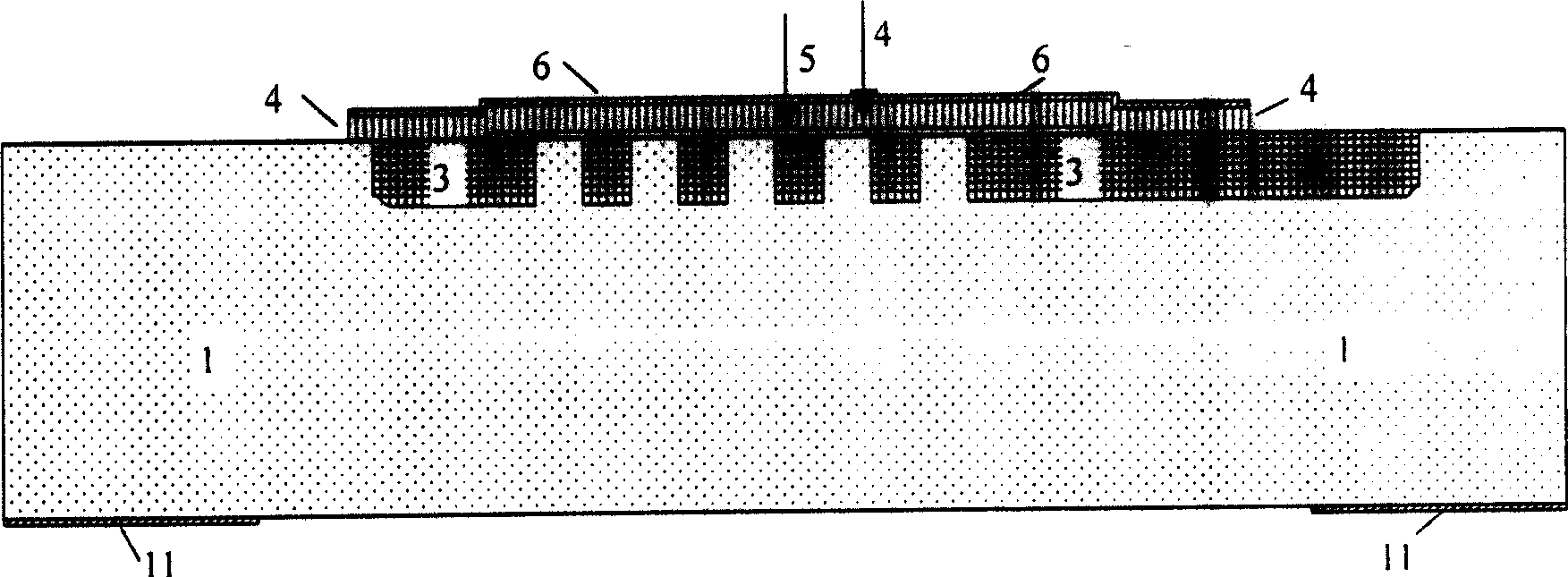

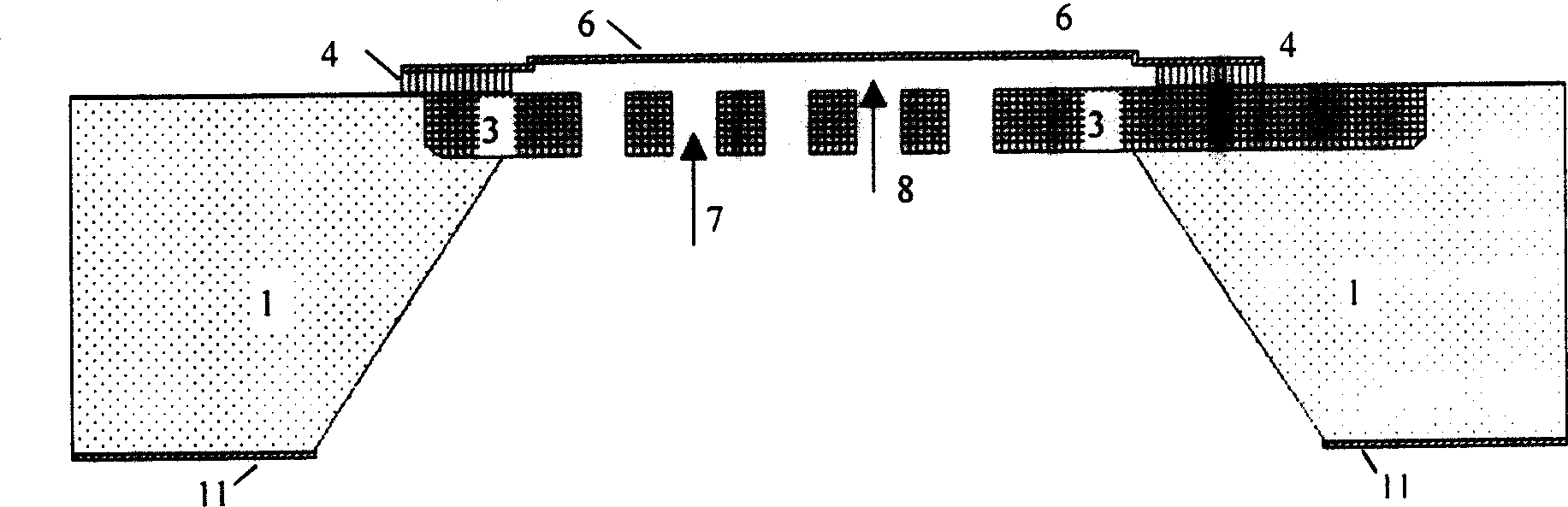

[0038] A kind of chip of the present invention that this embodiment provides is used in silicon microcapacitance microphone, see appendix Figure 4-6 ; The chip includes an n-type silicon substrate 1, and boron is diffused on the front side of the silicon substrate 1 to form a p+ type doped layer 3 with a thickness of 3 or 20 microns; at the p+ type doped layer 3, silicon dioxide is deposited and photoetched , Corroded into a ring-shaped isolation layer 4, the inner diameter of the annular isolation layer 4 is 500 or 3000 microns, and the radial width is 50 or 150 microns; a circular vibration made of silicon nitride is attached to the isolation layer 4 The film layer 6 is deposited on the vibrating film layer 6 and photoetched and corroded into a circular metal aluminum film and a square electrode 9, and uniform circular micro-perforations 10 are distributed on the edge of the vibrating film and the circular aluminum film; the circular The micro-perforation 10 has a diameter ...

Embodiment 2

[0040] combined with Figure 7 The preparation method of the present invention is described in detail with specific examples:

[0041] [1] Take an n-type silicon substrate 1 and grow a silicon dioxide with a thickness of 1.5 microns through high-temperature oxidation. After photolithography, use hydrofluoric acid to etch the high-temperature silicon dioxide to make a mask 2, and place it Carry out deep boron diffusion to form the p+ type doped layer 3 in the perforated backplane except for the hole distribution part, and the boron diffusion depth is 10 microns;

[0042] [2] After removing the high-temperature silicon dioxide mask with hydrofluoric acid, a 0.5-micron-thick zinc oxide auxiliary sacrificial layer is magnetron sputtered on the front of the silicon wafer, and a circular auxiliary sacrificial layer 5 is formed by photolithography and phosphoric acid etching. The diameter of the auxiliary sacrificial layer is 1000 microns, and the thickness is 0.5 microns; on the fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com