Preparation method for high-dielectric-constant formed aluminum foil

A high-dielectric-constant, aluminum-foil-forming technology, used in circuits, capacitors, anodizing, etc., can solve the problems of poor controllability, low dielectric constant and small specific capacity of finished aluminum electrode foils, and achieve higher specific capacity, improved Small relative dielectric constant and obvious effect of increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

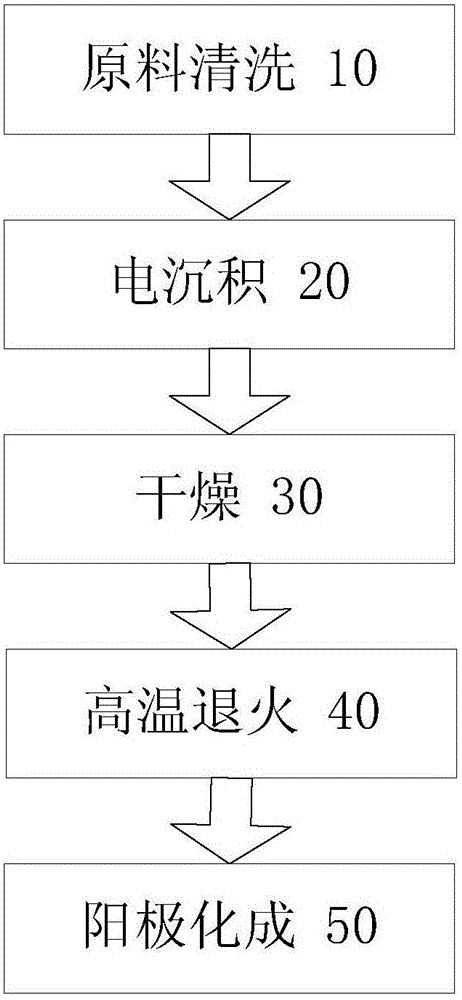

Method used

Image

Examples

Embodiment 1

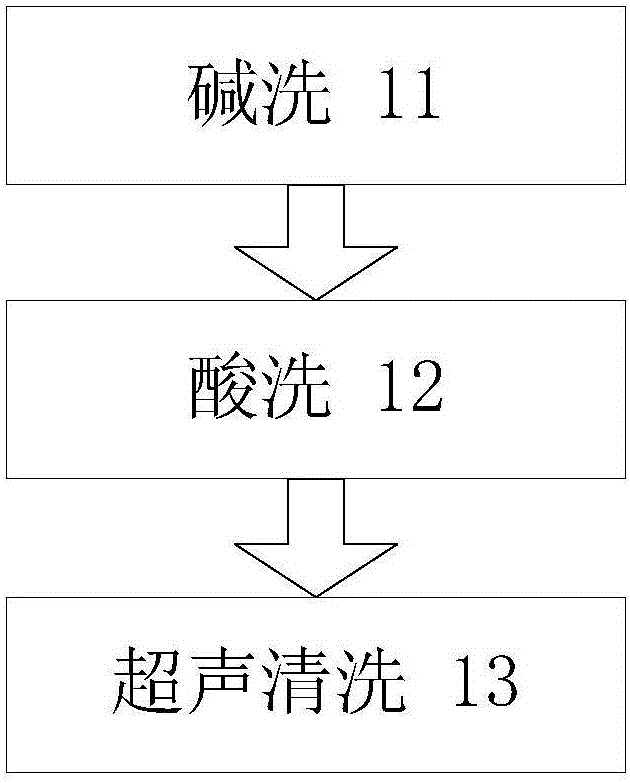

[0050] (11) Alkaline cleaning: The corroded foil used is cleaned in 1.0M sodium hydroxide solution for 60s.

[0051] (12) Pickling: Soak the above-mentioned corroded foil after alkali washing in a mixed acid solution of 1.0M hydrochloric acid and 3.0M sulfuric acid for 100s.

[0052] (13) Ultrasonic cleaning: the above-mentioned corroded foil after alkali cleaning was soaked in deionized water for 150s under ultrasonic conditions of ultrasonic power of 300W and ultrasonic frequency of 28kHz.

[0053] (20) Electrodeposition: immerse the above-mentioned corroded foil after a series of cleaning steps in a solution containing (NH 4 ) 2 [TiO(C 2 o 4 ) 2 ] and (COOH) 2 The electrochemical deposition is carried out in the deposition tank of the mixed solution. The electrodeposition solution consists of 0.005M (NH 4 ) 2 [TiO(C 2 o 4 ) 2 ] and 0.001M of (COOH) 2 Mix composition, by adding NH dropwise 4 OH to adjust the pH of the mixture to 4. The above-mentioned treated c...

Embodiment 2

[0058] (11) Alkaline cleaning: The corroded foil used is cleaned in 1.0M sodium hydroxide solution for 60s.

[0059] (12) Pickling: Soak the above-mentioned corroded foil after alkali washing in a mixed acid solution of 1.0M hydrochloric acid and 3.0M sulfuric acid for 100s.

[0060] (13) Ultrasonic cleaning: the above-mentioned corroded foil after alkali cleaning was dipped in a deionized water medium for 150s under ultrasonic conditions of ultrasonic power of 300W and ultrasonic frequency of 28kHz.

[0061] (20) Electrodeposition: immerse the above-mentioned corroded foil after a series of cleaning steps in a solution containing (NH 4 ) 2 [TiO(C 2 o 4 ) 2 ] and (COOH) 2 The electrochemical deposition is carried out in the deposition tank of the mixed solution. The electrodeposition solution consists of 0.01M (NH 4 ) 2 [TiO(C 2 o 4 ) 2 ] and 0.001M of (COOH) 2 Mix composition, by adding NH dropwise 4 OH to adjust the pH of the mixture to 4. The above-mentioned t...

Embodiment 3

[0066] (11) Alkaline cleaning: The corroded foil used is cleaned in 1.0M sodium hydroxide solution for 60s.

[0067] (12) Pickling: Soak the above-mentioned corroded foil after alkali washing in a mixed acid solution of 1.0M hydrochloric acid and 3.0M sulfuric acid for 100s.

[0068] (13) Ultrasonic cleaning: the above-mentioned corroded foil after alkali cleaning was dipped in a deionized water medium for 150s under ultrasonic conditions of ultrasonic power of 300W and ultrasonic frequency of 28kHz.

[0069] (20) Electrodeposition: immerse the above-mentioned corroded foil after a series of cleaning steps in a solution containing (NH 4 ) 2 [TiO(C 2 o 4 ) 2 ] and (COOH) 2 The electrochemical deposition is carried out in the deposition tank of the mixed solution. The electrodeposition solution consists of 0.01M (NH 4 ) 2 [TiO(C 2 o 4 ) 2 ] and 0.005M (COOH) 2 Mix composition, by adding NH dropwise 4 OH to adjust the pH of the mixture to 4. The above-mentioned trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com