Novel refined aluminium electrode and its using method

A refined aluminum and electrode technology, which is applied in the new refined aluminum electrode and its application field, can solve problems such as uneven conduction of electrodes, quality accidents, and increased resistance, and achieve the effects of reducing power consumption per ton of aluminum, improving quality, and reducing voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

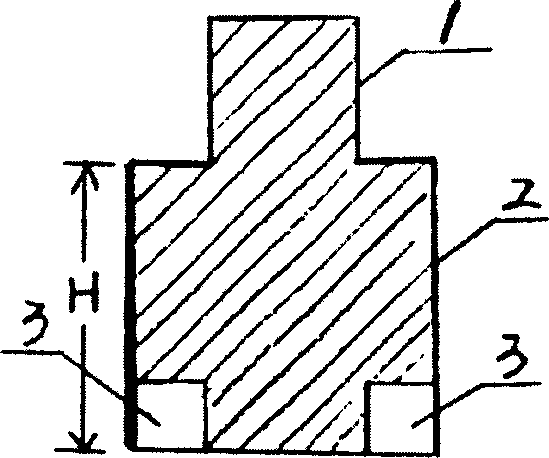

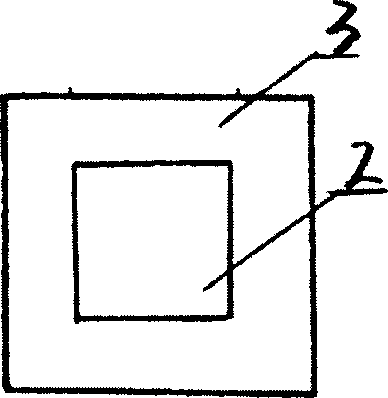

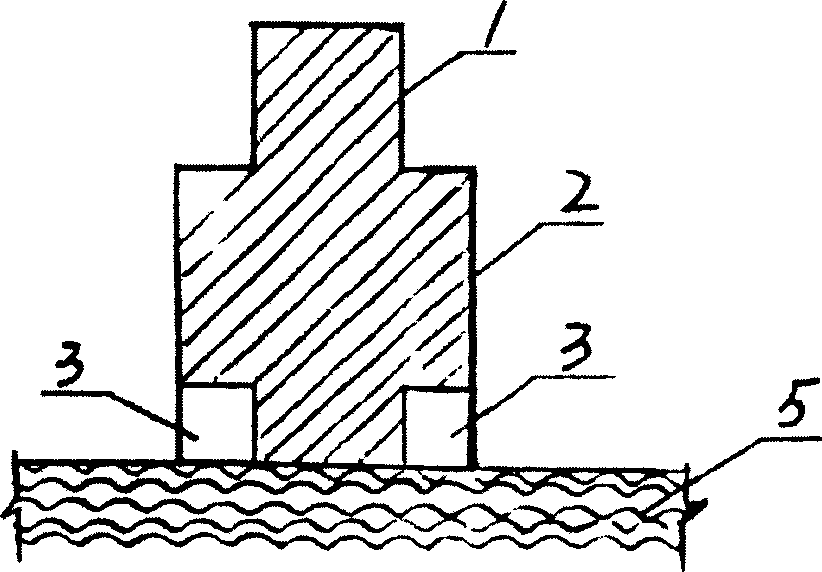

[0026] Embodiment 1, as attached figure 1 with 2 As shown, the new refined aluminum electrode includes a solid refined aluminum cathode. The solid refined aluminum cathode includes a guide rod 1 and an electrode 2. On the outer side of the bottom palm of the electrode 2, there is a material that can withstand high temperature, resist rapid cooling and heat, and does not pollute the refined aluminum liquid. An electrode ring 3, and the electrode ring 3 and the electrode 2 are fixed and integrated. as attached image 3 As shown, the use method of the novel refined aluminum electrode is as follows: the use method includes a three-layer liquid aluminum electrolytic refining method, the three-layer liquid aluminum electrolytic refining method includes a three-layer liquid refined aluminum electrolytic cell, and the new refined aluminum electrode is used as a cathode , the bottom end of the novel refined aluminum electrode is immersed in the refined aluminum solution in the three-...

Embodiment 2

[0027] Embodiment 2, as attached figure 1 , 2 , 4 and 5, the difference between embodiment 2 and embodiment 1 is that there is a protective layer 4 on the outside of the electrode ring 3 to prevent the electrode ring from being oxidized; ) protected in the working environment, thereby prolonging the service life of the novel refined aluminum electrode of the present invention. as attached Image 6 As shown, the use method of the novel refined aluminum electrode is as follows: the use method includes a three-layer liquid aluminum electrolytic refining method, the three-layer liquid aluminum electrolytic refining method includes a three-layer liquid refined aluminum electrolytic cell, and the new refined aluminum electrode is used as a cathode The bottom end of the novel refined aluminum electrode is immersed in the refined aluminum liquid in the three-layer liquid refined aluminum electrolytic cell for 2 cm or 3 cm or 4 cm or 5 cm.

[0028] In order to further improve perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com