Magnetic drive micro-inertial sensor for increasing detection capacitance and preparation method

A technology for micro-inertial sensors and capacitance detection, applied in chemical instruments and methods, components of TV systems, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problem of increasing the mass of sensor vibrators and reducing the distance between pole plates , increase the mechanical noise of the sensor, and the large air damping of the laminated film, etc., to achieve the effect of novel structure, reducing air damping, and reducing mechanical noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

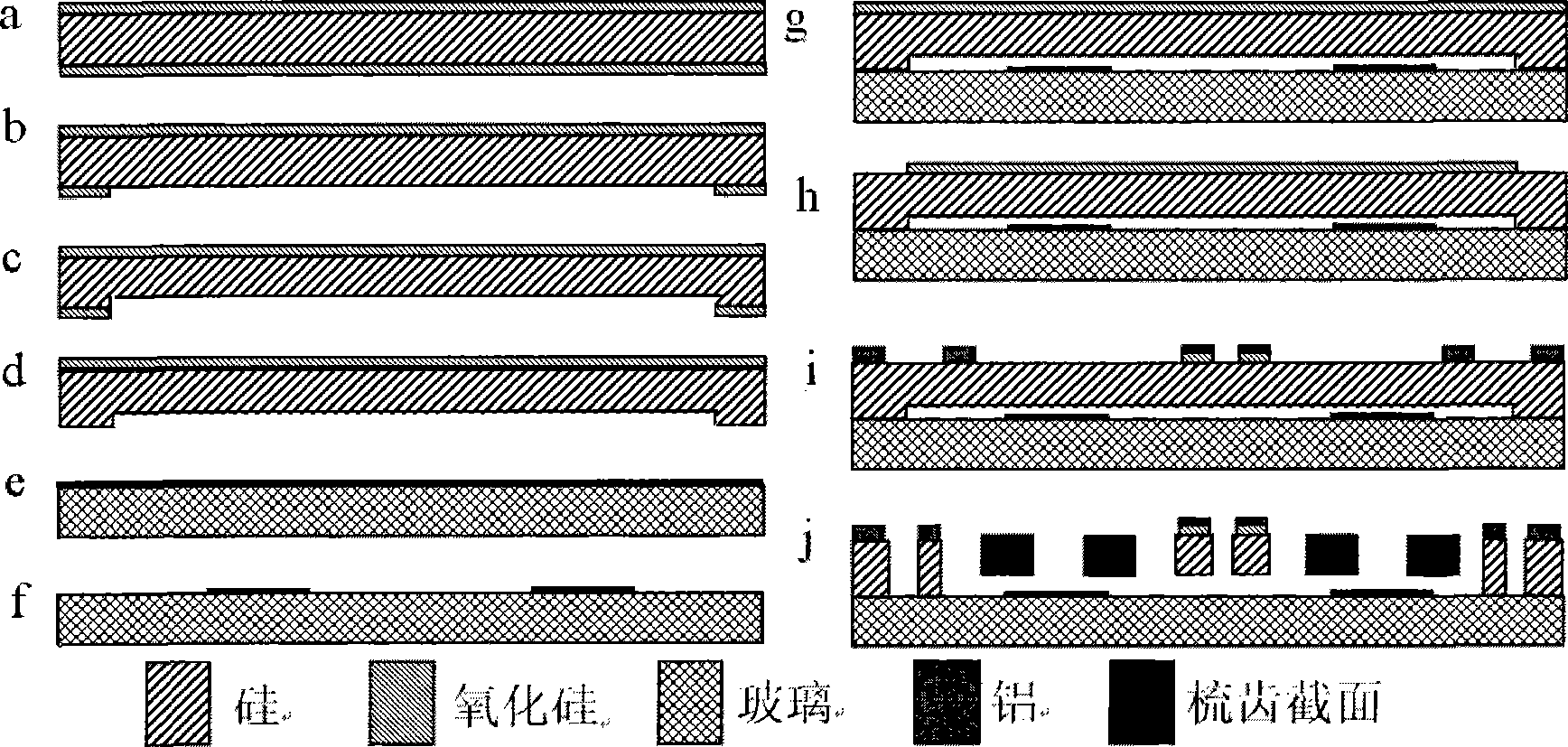

[0023] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is by no means limited to the described embodiments.

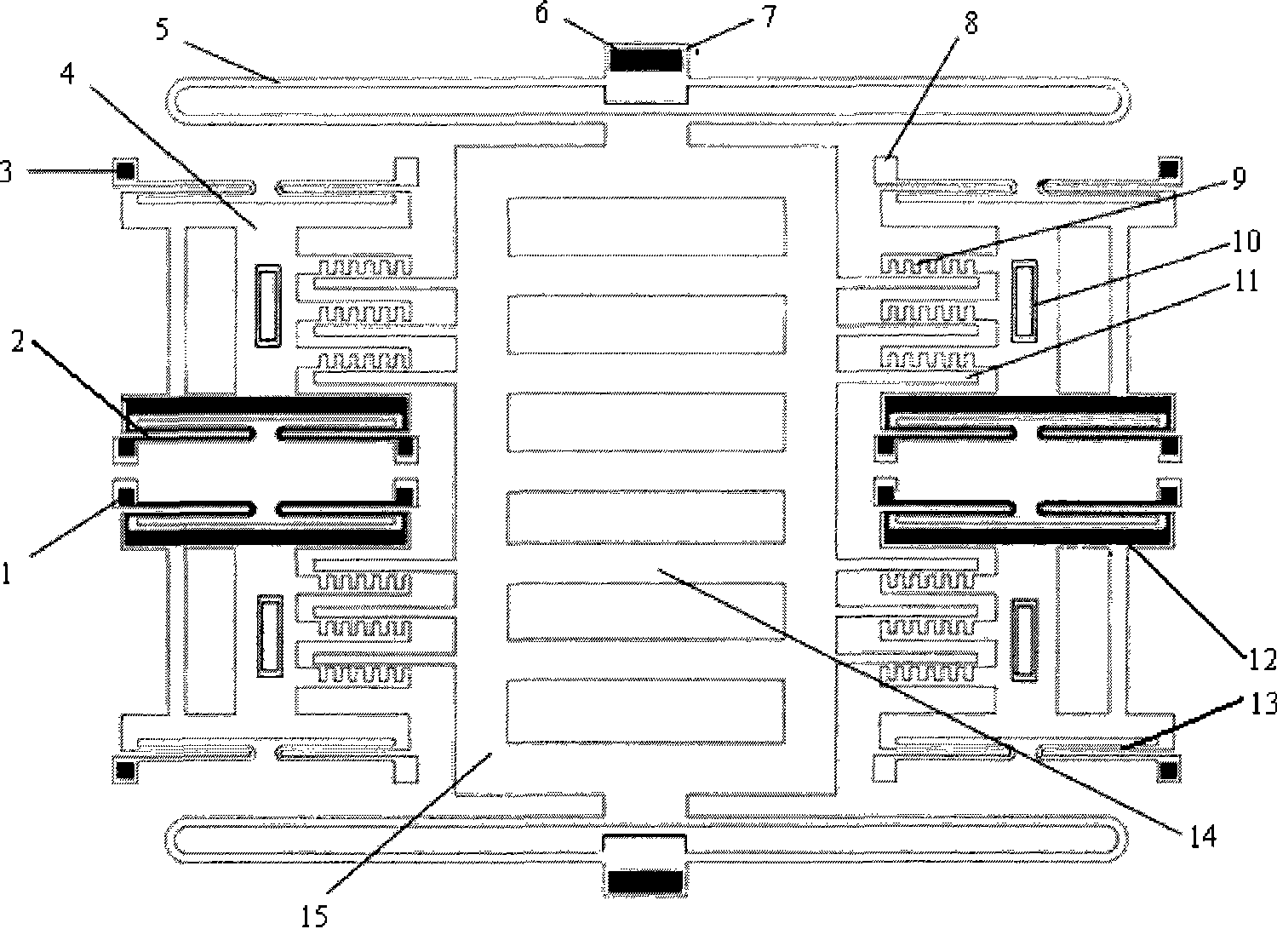

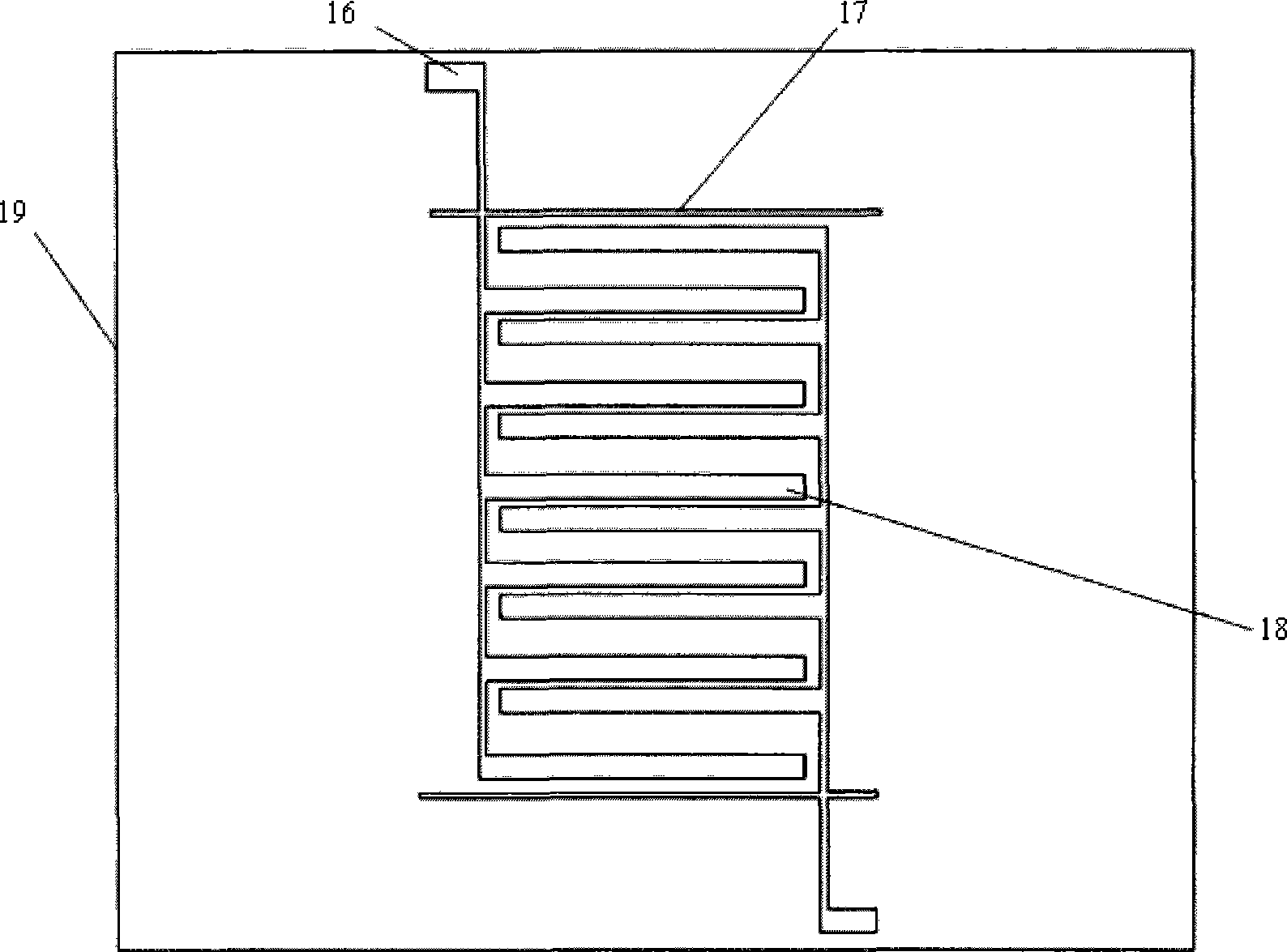

[0024] Such as figure 1 and figure 2 As shown, a micro-inertial sensor with magnetically driven and increased detection capacitance includes a glass substrate 19 , a sensor mass 15 , and a driver mass 4 .

[0025] The main body of the sensor mass 15 is a rectangular silicon wafer, and the two ends of the sensor mass 15 are connected to the sensor anchor point 7 through the U-shaped sensor silicon support beam 5, and the sensor anchor point 7 is fixedly arranged on the glass substrate 19; The two sides of the sensor mass 15 are respectively symmetrically provided with two groups of silicon strip groups, and each group of silicon strip groups includes three silicon strips 11 arranged in parallel, and each silicon strip 11 is perpendicular to the side of the sensor mass 15; G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com