Resistance welding method

A technology of resistance welding and resistance spot welding, applied in the direction of resistance welding equipment, welding equipment, electrode characteristics, etc., can solve the problems of low welding efficiency, failure to achieve welding effect, easy sticking of spot welding head to aluminum electrodes, etc., and improve the use of The effect of life and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

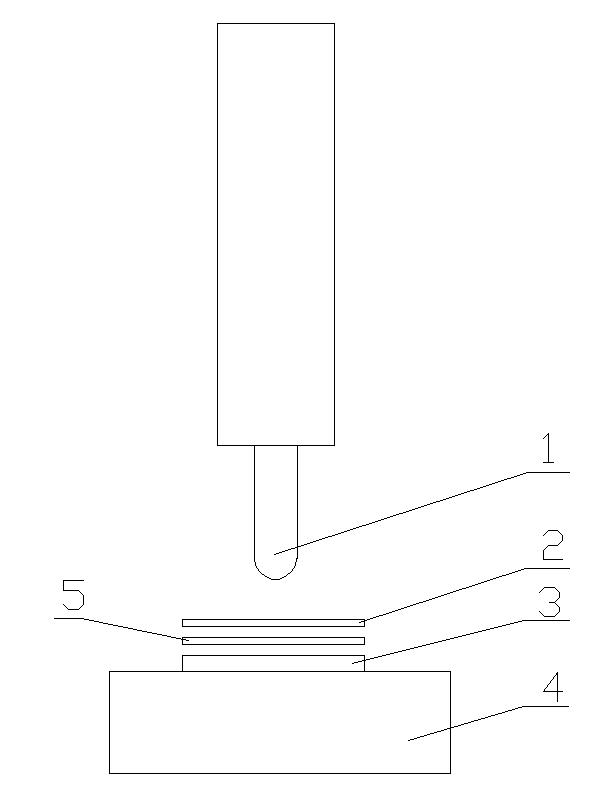

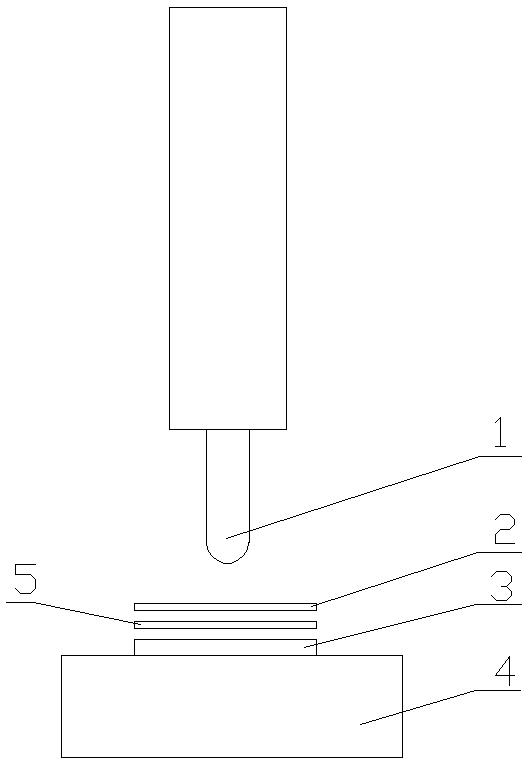

[0009] The resistance welding method of the invention can be used for resistance welding of aluminum electrodes of electric vehicle batteries. , Adjust the parameters before welding, set the preload time to 650ms, the first time to 2s, the current to be 25% of the whole, and the number of pulses to 1. Install the aluminum electrode to be spot welded on the CD spot welding platform 4, and then put the The thin aluminum foil 5 is placed on the aluminum electrode 3, and then a thin copper foil 2 with a thickness of about 0.2mm is placed on the thin aluminum foil. Press the control pedal, and the CD spot welding head 1 welds the thin aluminum foil and the aluminum electrode. After the spot welding is completed Peel off the thin copper foil on the aluminum foil, and the soldering is complete. Because when welding thin aluminum electrodes, a thin copper sheet is separated between the spot welding head and the electrode, and the part that the spot welding head contacts during w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com