Electronic component embedded circuit board and manufacturing method thereof

A technology of electronic components and manufacturing methods, which is applied in the direction of assembling printed circuits with electrical components, printed circuit manufacturing, and printed circuits connecting non-printed electrical components, etc. Incompatibility of circuit board manufacturing process, corrosion and damage of aluminum electrode chemical substances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment of the present invention provides an electronic component embedded circuit board and a manufacturing method thereof, which adopts a technical solution of zincizing and nickel-plating the aluminum electrodes of the electronic components embedded in the circuit board. The obtained zinc-nickel protective layer protects the aluminum electrodes, so that the aluminum electrodes will not be damaged by lasers, various acidic or alkaline chemical solutions in the circuit board manufacturing process, including laser blind hole processing, etching and other processes. Each will be described in detail below.

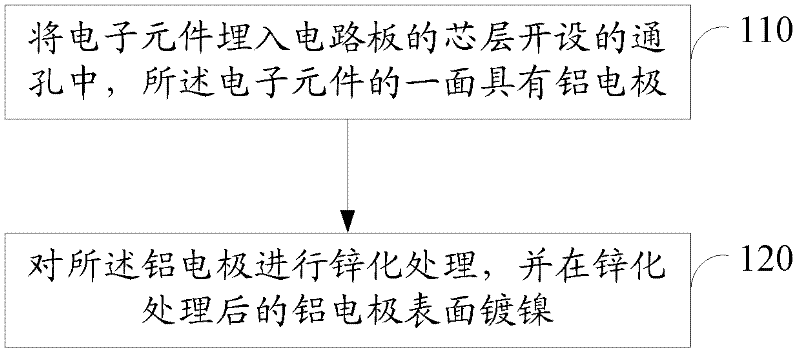

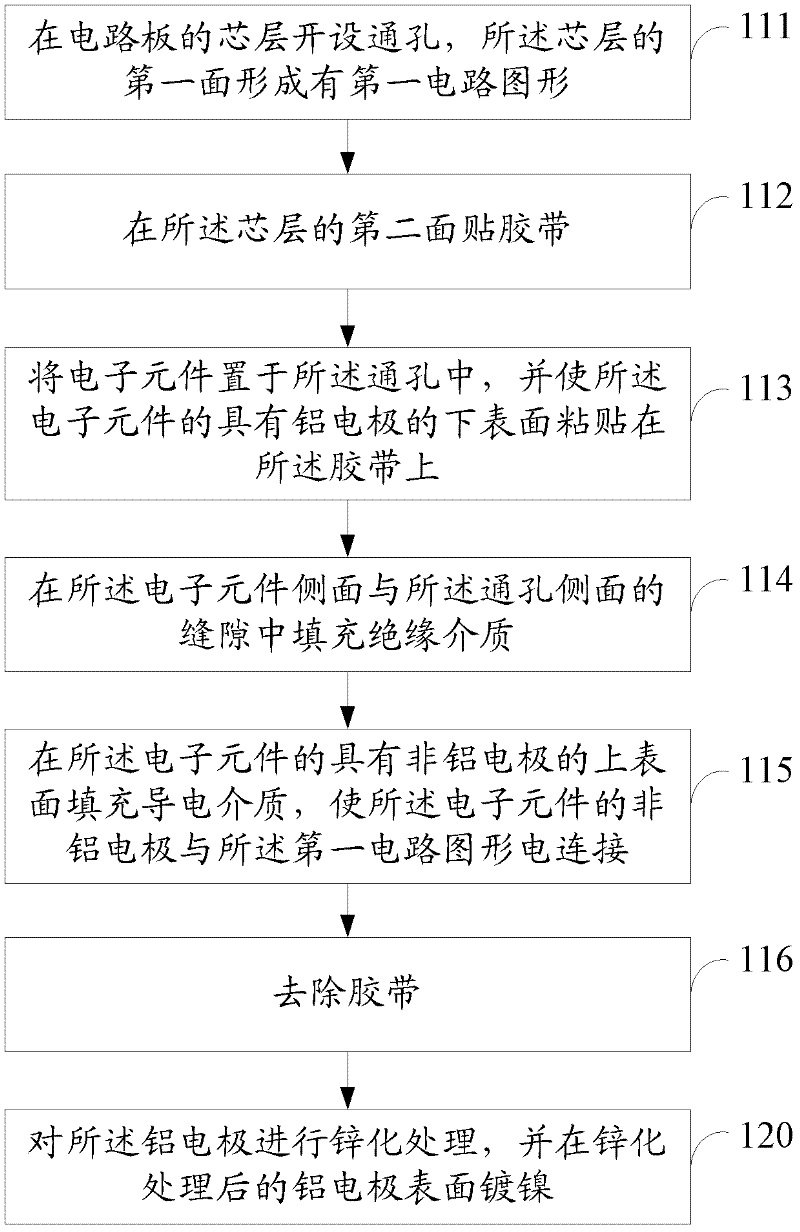

[0017] Please refer to Figure 1a , an embodiment of the present invention provides a method for manufacturing an electronic component embedded circuit board, including:

[0018] 110. Embedding electronic components into the through holes opened in the core layer of the circuit board, one side of the electronic components has aluminum electrodes.

[0019] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com