Piezoelectric ceramic element of metal aluminium electrode and preparation method thereof

A piezoelectric ceramic element and metal electrode technology, which is applied in the field of piezoelectric ceramic elements, can solve the problems of the difference in the combination of electrode materials and base materials, the easy falling off of electrode materials, and the falling off of electrodes, so as to achieve good electrical conductivity, reduced production costs, The effect of high adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, the piezoelectric ceramic sounding element (piezoelectric buzzer chip) is taken as an example. The inverse piezoelectric effect, which converts electrical energy of piezoelectric ceramic materials into mechanical energy, is used to produce sound-generating components. Such sound-generating components have been widely used in various electronic instruments and equipment, household appliances, electronic toys, etc. Its preparation method is to print silver electrode paste on the two ends of the sintered lead zirconate titanate (PZT) ceramics, make electrodes through high-temperature reduction, and then polarize and paste metal vibrating pieces to make piezoelectric ceramics. Buzzer, piezoelectric ceramic buzzer can be directly used as a sounding element, or piezoelectric ceramic buzzer can be put into a plastic resonance cavity to make a piezoelectric buzzer.

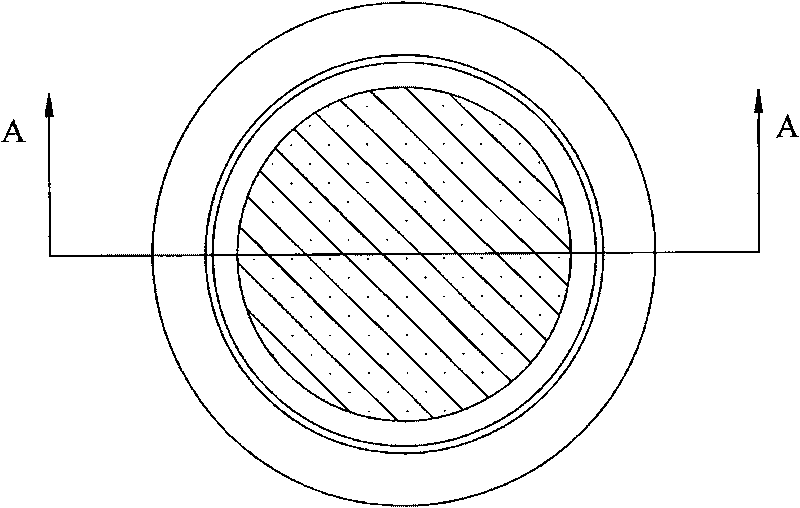

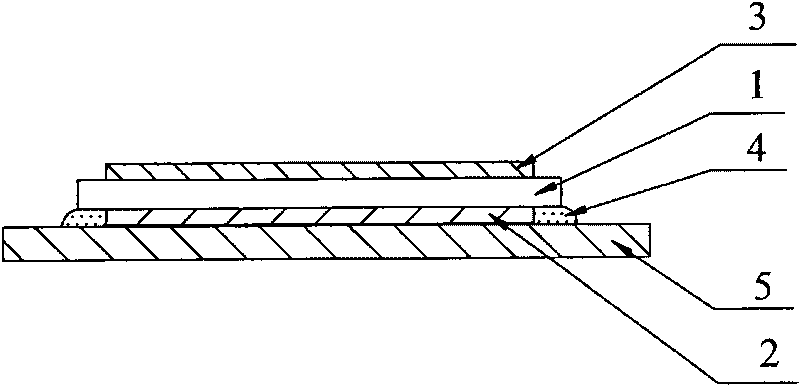

[0038]As shown in FIG. 1 , the piezoelectric buzzer ceramic chip includes sintered PZT ceram...

Embodiment 2

[0053] Some specifications of the piezoelectric ceramic buzzer do not use welding to connect the internal piezoelectric buzzer and the lead-out wire, but use the elastic contact method of metal parts, that is, the external excitation electrical signal is connected to the bee card electrode through the elastic metal member. , to make the buzzer sound.

[0054] In order to reduce costs, the piezoelectric ceramic sheet electrodes of this type of buzzer can be made of aluminum electrode paste on one or both sides. When aluminum electrodes are used on one side, the appearance of the piezoelectric buzzer is better, that is, the electrode on one side that is pasted with the metal vibrating piece is made into an aluminum electrode, and the side that is in contact with the metal elastic member is made from a silver electrode. The method of making an aluminum electrode on one side is described in the embodiment 1 has been described. When aluminum electrodes are used on both sides, alth...

Embodiment 3

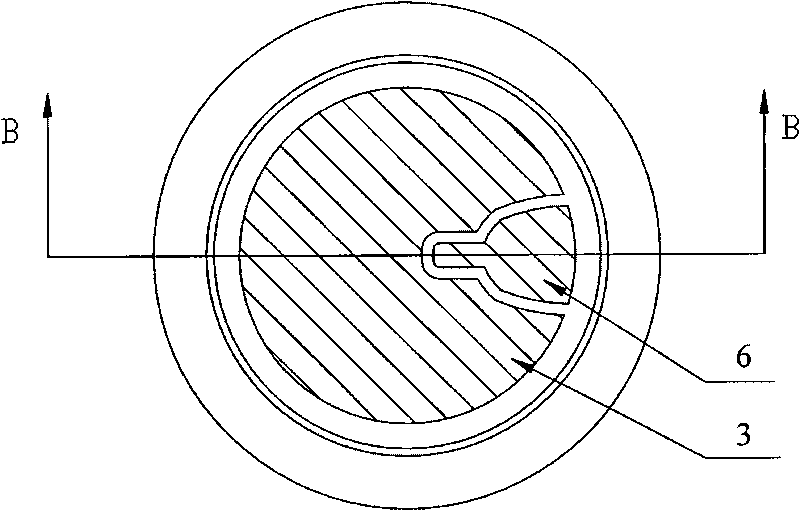

[0063] Using aluminum electrode paste to make electrodes on both sides of the piezoelectric ceramic element can further reduce product cost. Although the aluminum electrode can conduct electricity similarly to the silver electrode, the excitation signal lead wire of the buzzer cannot be welded on the aluminum electrode by soldering. Silver electrodes, and aluminum electrodes for the rest, see Figure 3.

[0064] In this implementation, the purchased silver electrode paste (DS-PF-7170VR paste produced by Shanghai Dazhou Electronic Materials Co., Ltd.) was used to make silver electrodes. The production method of the aluminum electrode slurry adopted is the same as that of Example 1 and Example 2. According to the total mass percentage of the formula raw materials, the aluminum electrode slurry consists of: 58% metal aluminum powder, 13% low-melting point lead-free glass Powder, 1% antioxidant additive (wherein amorphous boron powder and red phosphorus are half and half), 18% eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com