Zinc oxide resistor aluminium spraying device and aluminium spray process thereof

A technology of zinc oxide resistance sheet and process, which is applied in the direction of resistors, resistance manufacturing, circuits, etc., can solve the problems of cost of funds, easy to loose, and a large amount of labor, so as to achieve high spraying efficiency, improve flow capacity, and reduce labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

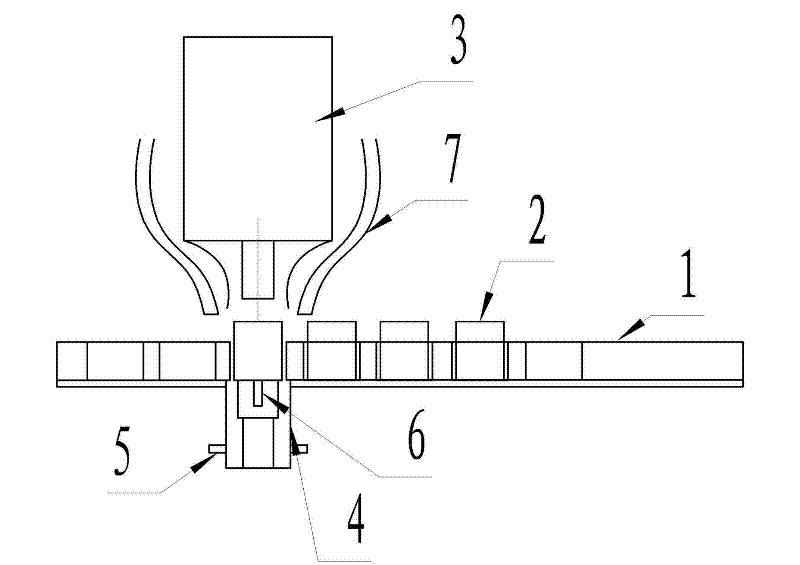

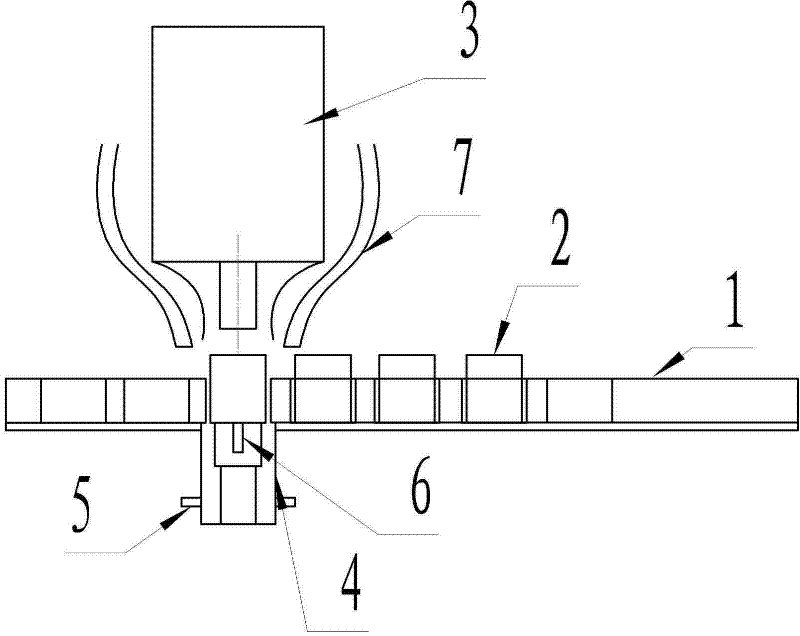

[0010] Such as figure 1 According to the present invention, the aluminum spraying device for zinc oxide resistors includes a spray gun 3, a conveyor belt 1, a gas blowing platform 4 and a waste gas collection pipe 7; the gas blowing platform is installed below the conveyor belt, and the spray gun is placed above the corresponding position of the gas blowing platform; The collection pipes are mounted on both sides of the spray gun.

[0011] The process of spraying aluminum electrodes on zinc oxide resistors includes the following steps:

[0012] The operator places the zinc oxide resistor 2 on the conveyor belt 1, and the conveyor belt 1 sends the zinc oxide resistor 2 to the blowing table 4 below the spray gun 3, and the sensor 6 in the blowing table 4 senses the zinc oxide resistor 2. , the spraying switch of the spray gun 3 and the air valve of the air blowing table 4 below are opened at the same time, and the aluminum electrode is sprayed; The mouth enters and forms high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com