Method for preparing polysilicon solar battery suede in magnetic field

A technology of solar cells and polysilicon, which is applied in the manufacture of circuits, electrical components, and final products, and can solve problems such as the absence of polysilicon solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

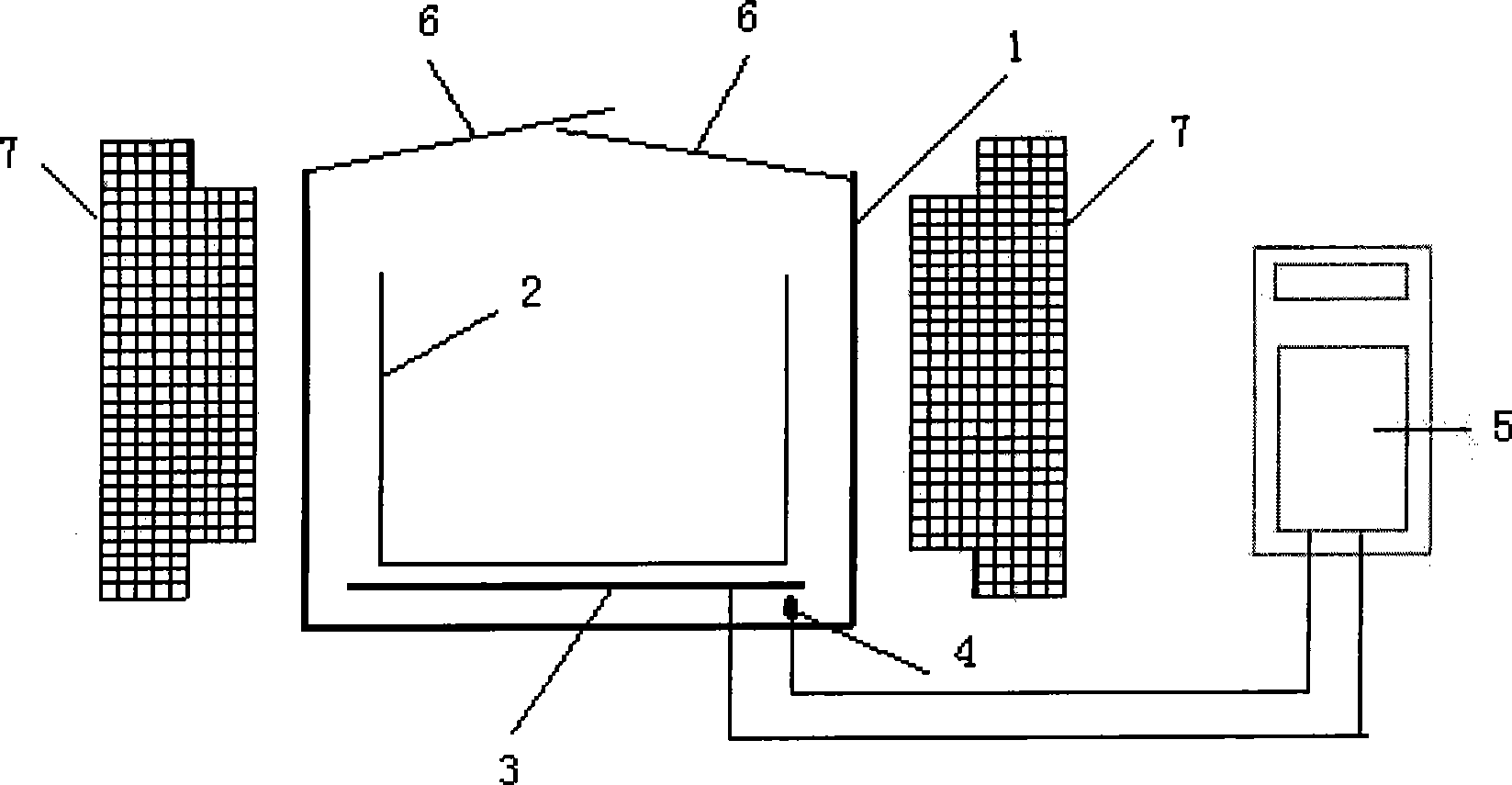

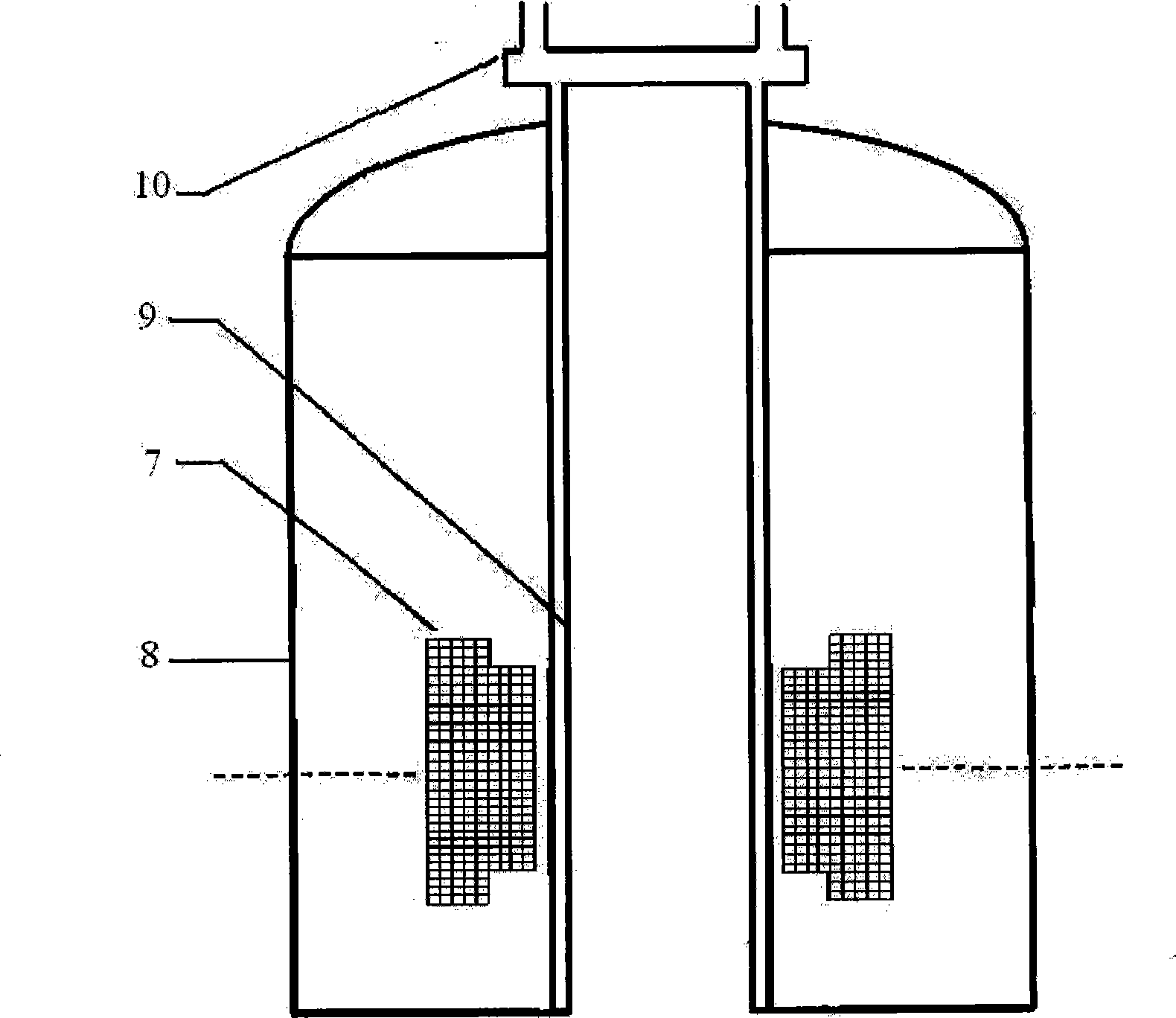

[0017] The invention adopts the technique of preparing polycrystalline silicon solar cell suede surface under magnetic field, so as to prepare high-quality and uniform suede surface. The raw materials are electronically pure sodium hydroxide or potassium hydroxide, and polycrystalline silicon wafers. It adopts the texturing tank with computer precise control heater. First, a certain amount of deionized water is passed into the suede preparation reactor, which is just above the height of the silicon wafer, and then a certain amount of sodium hydroxide or potassium hydroxide, ethanol or isopropanol, and sodium silicate are added. Wherein the mass percent of sodium hydroxide or potassium hydroxide in the reaction solution remains at 0.05% to 15%, the mass percent of ethanol or isopropanol in the reaction solution remains at 5% to 25%, and sodium silicate in the reaction solution The mass percentage of the solution is kept at 0.05% to 3%, the temperature of the solution is kept a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com