Fertilizer processing device

A fertilizer processing and bucket technology, applied in the field of fertilizer processing devices, can solve the problems of low flexibility, uneven mixing and mixing, and adjusting the distribution positions of different kitchen wastes, so as to improve the utilization rate, high flexibility, and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

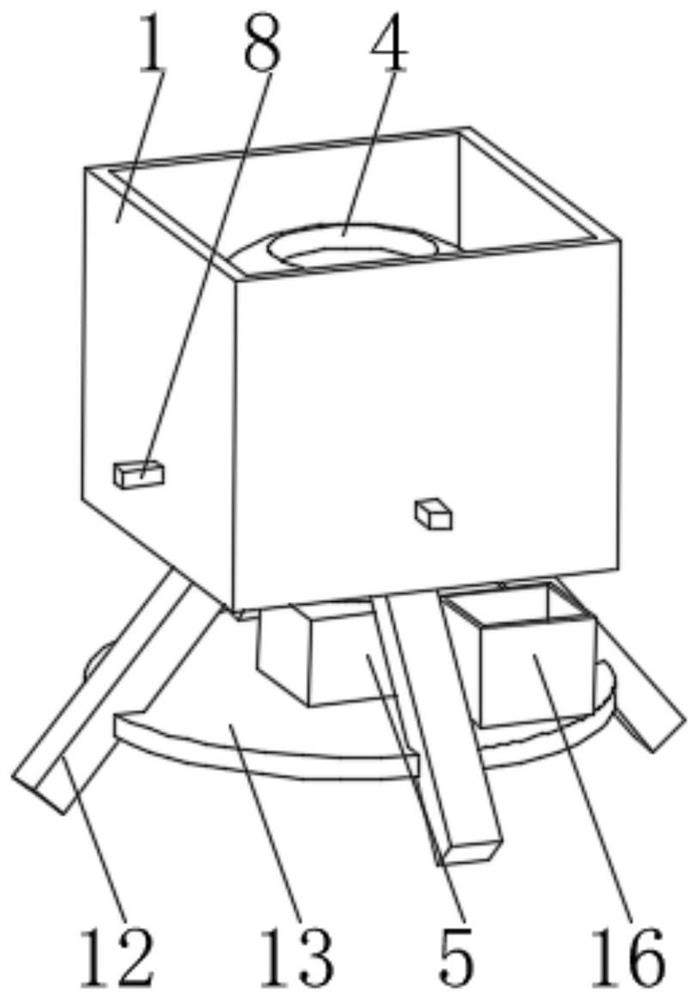

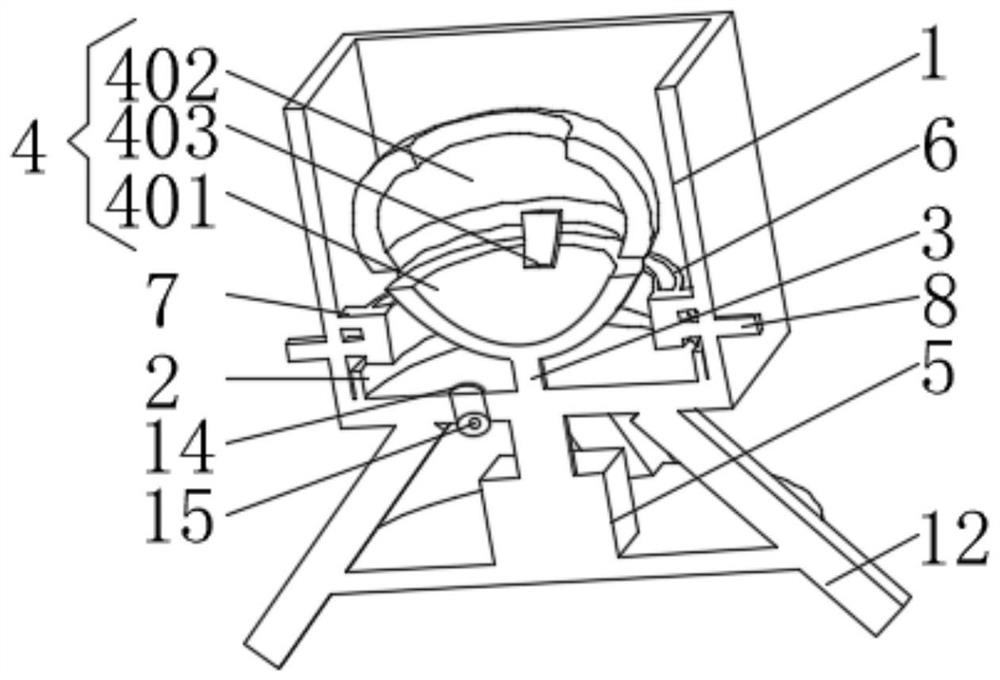

[0027] see Figure 1-3 , the present invention provides a technical solution: a fertilizer processing device, including a processing barrel 1, a stirring bottom box 2 is installed on the inner bottom of the processing barrel 1, and a material distribution barrel is fixedly connected to the inner bottom of the stirring bottom box 2 through a connecting rod 3 4. A stirring motor 5 is installed at the bottom of the processing barrel 1. The output end of the stirring motor 5 runs through the processing barrel 1 and is connected with the stirring bottom box 2. The bottom is located below the intercepting net 9 and evenly provided with discharge holes 11 .

[0028] The material distribution bucket 4 includes a material box 401, a guide frame 402 is installed above the material box 401, the guide frame 402 is located outside the material box 401, and the material box 401 and the guide frame 402 are fixedly connected by a connecting plate 403.

[0029] The bottom of the processing ba...

Embodiment 2

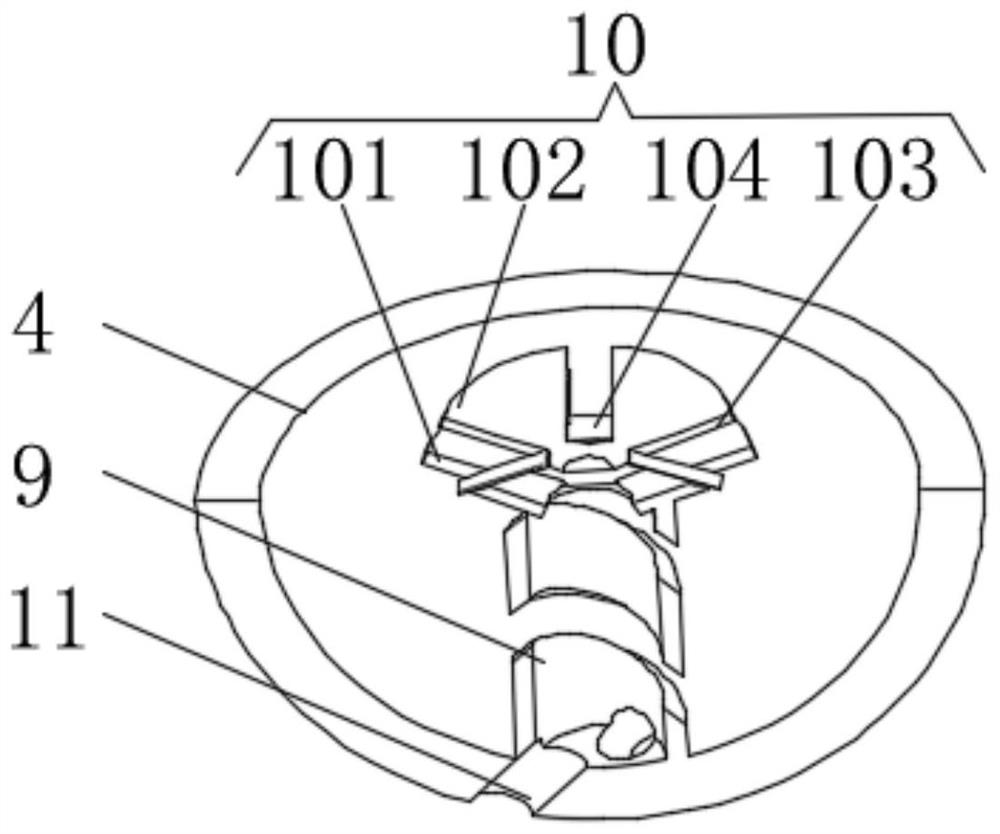

[0033] see Figure 1-3 , the present invention provides a technical solution: on the basis of Embodiment 1, a collection device 10 is installed on the top of the intercepting net 9, the collection device 10 includes a bottom disc 101 and an upper disc 102, and the bottom of the bottom disc 101 is an opening According to the design, the top of the bottom disc 101 is uniformly provided with a longitudinal groove 103, the longitudinal groove 103 runs through the bottom disc 101 and the upper disc 102, and a guide plate 104 is fixedly connected between the two sides of the inner wall of the longitudinal groove 103.

[0034] During use, the kitchen waste with a heavier quality rises to the top along the inner wall of the distribution bucket 4 and then falls towards the direction of the intercepting net 9, and the kitchen waste passes through the position between the bottom disc 101 and the upper disc 102. Afterwards, it falls into the intercepting net 9, and part of the kitchen was...

Embodiment 3

[0036] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, a guide ring 6 is installed inside the processing barrel 1, the top of the guide ring 6 is fixedly connected with the processing barrel 1 through a connecting block 7, and the bottom of the guide ring 6 is installed There is a control rod 8 , and the end of the control rod 8 away from the guide ring 6 penetrates the processing barrel 1 and extends to the outside of the processing barrel 1 .

[0037] The guide ring 6 includes a top ring 601, the connecting block 7 is fixedly connected to the top ring 601, the bottom ring 602 is installed below the top ring 601, the control rod 8 is connected to the bottom ring 602, the top ring 601 and the bottom ring 602 are hollow rings, A rubber sleeve 603 is fixedly connected between the top ring 601 and the bottom ring 602, and both ends of the rubber sleeve 603 are designed with openings.

[0038] The bottom ring 602 includes a cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com