Preparation method of three-dimensional silicon nano structure for solar cell

A technology of solar cells and silicon nanometers, applied in nanotechnology, chemical instruments and methods, circuits, etc., can solve the problems of high reflectivity, achieve large specific surface area, controllable process, and enhance the effect of light trapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

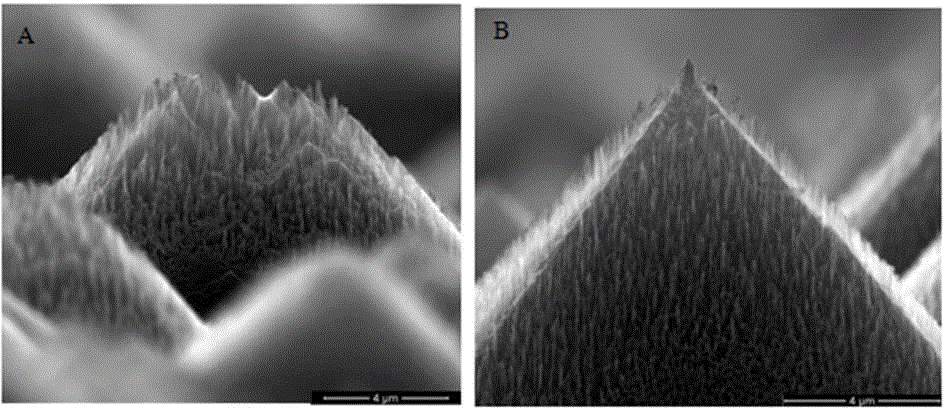

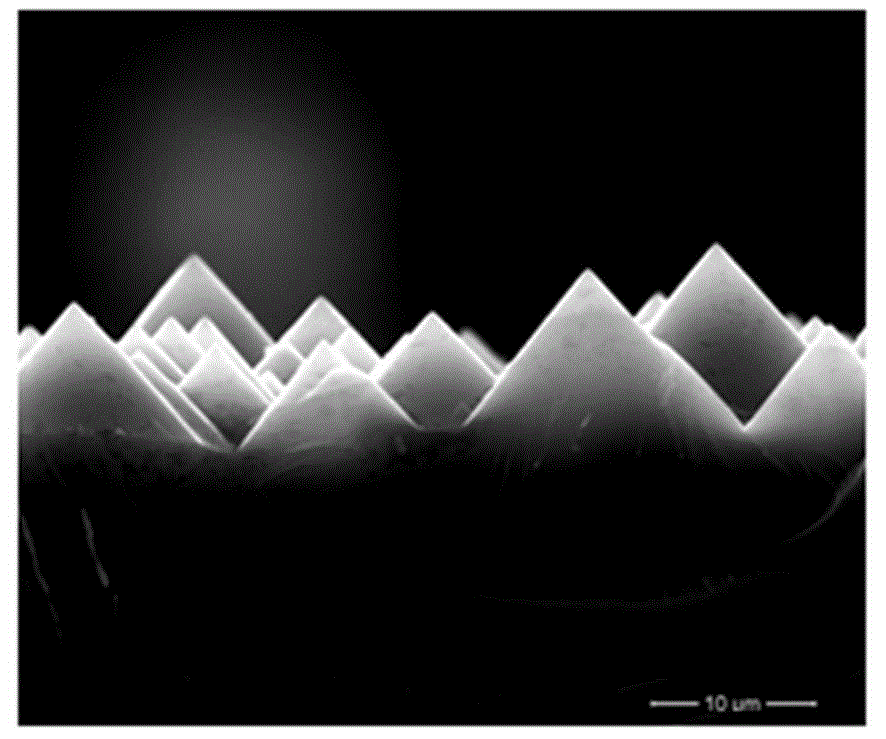

[0029] Put the cleaned silicon wafer into a mixed solution of 1.8% sodium hydroxide by mass and 10% ethanol by volume, and soak it at 80°C for 30 minutes to etch the "pyramid"-like suede structure; then remove Sodium hydroxide remaining on the surface of the silicon wafer, then remove the oxide layer on the surface of the silicon wafer, after further cleaning the silicon wafer, put it into 4.8M / L HF and 0.02M / L AgNO 3 In the mixed solution, silicon nanowires were etched at room temperature for 4 minutes, and then the removed silicon wafer was soaked in nitric acid for 1 hour, rinsed with deionized water after removal, and dried with a nitrogen gun to obtain a new three-dimensional Silicon nanostructure, its side SEM image is attached figure 2 shown.

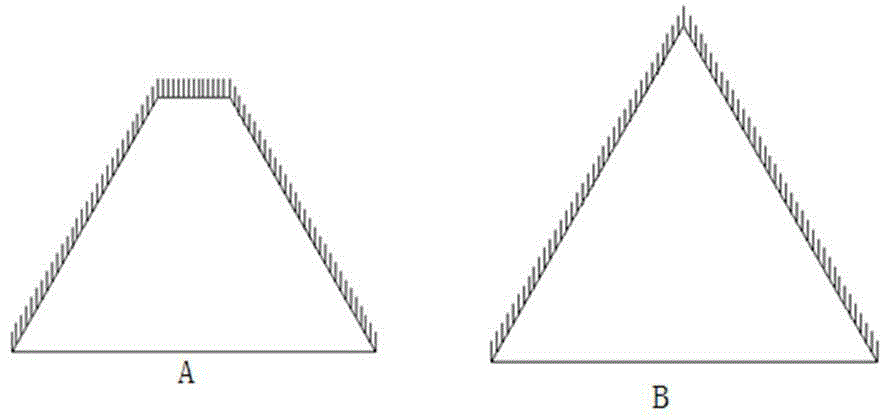

[0030] attached figure 1 It is a schematic diagram of the three-dimensional nanostructure prepared by the present invention, wherein A and B are respectively associated with the attached figure 2 correspond to figure 2 It ...

Embodiment 2

[0033] Put the cleaned silicon wafer into a mixed solution of 1.8% sodium hydroxide by mass and 10% ethanol by volume, and soak it at 80°C for 30 minutes to etch the "pyramid"-like suede structure; then remove Sodium hydroxide remaining on the surface of the silicon wafer, then remove the oxide layer on the surface of the silicon wafer, after further cleaning the silicon wafer, put it into 4.8M / L HF and 0.02M / L AgNO 3 In the mixed solution, silicon nanowires were etched at room temperature for 5 minutes, and then the removed silicon wafer was soaked in nitric acid for 1 hour, rinsed with deionized water after removal, and dried with a nitrogen gun to obtain a new three-dimensional Silicon nanostructures.

Embodiment 3

[0035] Put the cleaned silicon wafer into a mixed solution of 1.8% sodium hydroxide by mass and 10% ethanol by volume, and soak it at 80°C for 30 minutes to etch the "pyramid"-like suede structure; then remove Sodium hydroxide remaining on the surface of the silicon wafer, then remove the oxide layer on the surface of the silicon wafer, after further cleaning the silicon wafer, put it into 4.8M / L HF and 0.02M / L AgNO 3 In the mixed solution, silicon nanowires were etched at room temperature for 6 minutes, and then the removed silicon wafer was soaked in nitric acid for 1 hour, rinsed with deionized water after removal, and dried with a nitrogen gun to obtain a new three-dimensional Silicon nanostructures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com