Method for preparing crystalline silicon nanometer and micrometer composite texture surface

A technology of crystalline silicon and suede, which is applied in the direction of semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of damaged layer, high production cost, and reduce battery reflectivity, etc., so as to enhance the light trapping effect and improve Utilization rate, effect of increasing absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

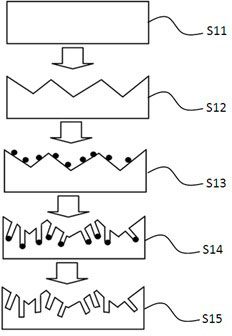

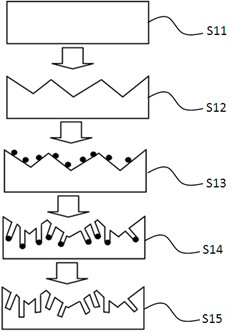

[0015] Embodiment 1: the monocrystalline silicon wafer is cleaned, and the alkaline etching solution is used for cashmere, forming a pyramid-shaped suede surface; then the silicon wafer is immersed in Na 2 S 2 o 8 and AgNO 3 In the aqueous solution, nanoscale silver particles are formed by chemical reduction and deposition on the surface of the silicon chip, and the particle size of the silver particles is 50nm; 2 o 2 and H 2 Selective etching in the chemical etching solution composed of O, HF: H 2 o 2 :H 2 The volume ratio of O is 1:(0.5~5):(5~20), preferably 1:5:20, the etching time is 3~10min, preferably 10min; finally put the silicon wafer into 50% concentrated HNO 3 solution to remove silver particles.

Embodiment 2

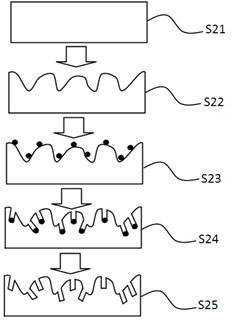

[0016] Example 2: Clean the single crystal silicon wafer, and make texture with alkaline corrosion solution to form a pyramid-shaped texture; then coat a layer of nano-gold particle emulsion wrapped by polymer on the surface of the silicon wafer, and the particle size of the gold particle is 5nm , dried; then put the silicon wafer covered with gold particles into 49% HF, 30% H 2 o 2 and H 2 Selective etching in the chemical etching solution composed of O, HF: H 2 o 2 :H 2 The volume ratio of O is 1:(0.5~5):(5~20), preferably 1:0.5:5; the etching time is 3~10min, preferably 3min; finally put the silicon wafer into the aqueous solution of KI and I2 to remove gold particles.

Embodiment 3

[0017] Embodiment 3: The monocrystalline silicon wafer is cleaned, and the alkaline corrosion solution is used to make texture to form a pyramid-like texture; then a layer of discontinuous nano-platinum particle layer is sputtered on the surface of the silicon wafer, and the particle size of the platinum particle is 30nm; then Put the silicon wafer covered with platinum particles into 49% HF and 30% H 2 o 2 and H 2 Selective etching in the chemical etching solution composed of O, HF: H 2 o 2 :H 2 The volume ratio of O is 1:(0.5~5):(5~20), preferably 1:3:10; the etching time is 3~10min, preferably 5min; finally put the silicon wafer into the aqua regia solution to clean and remove the platinum particles .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com