Method for regulating and controlling multiferroic BiFeO3 epitaxial film band gap on SrTiO3 substrate

An epitaxial thin film, bismuth ferrite technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve the problems of insufficient photovoltaic conversion efficiency, low photovoltaic conversion efficiency, and restricting the practical process, etc. Achieve the effect of enhancing photovoltaic conversion efficiency, easy large-scale promotion and application, complete growth process and post-treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

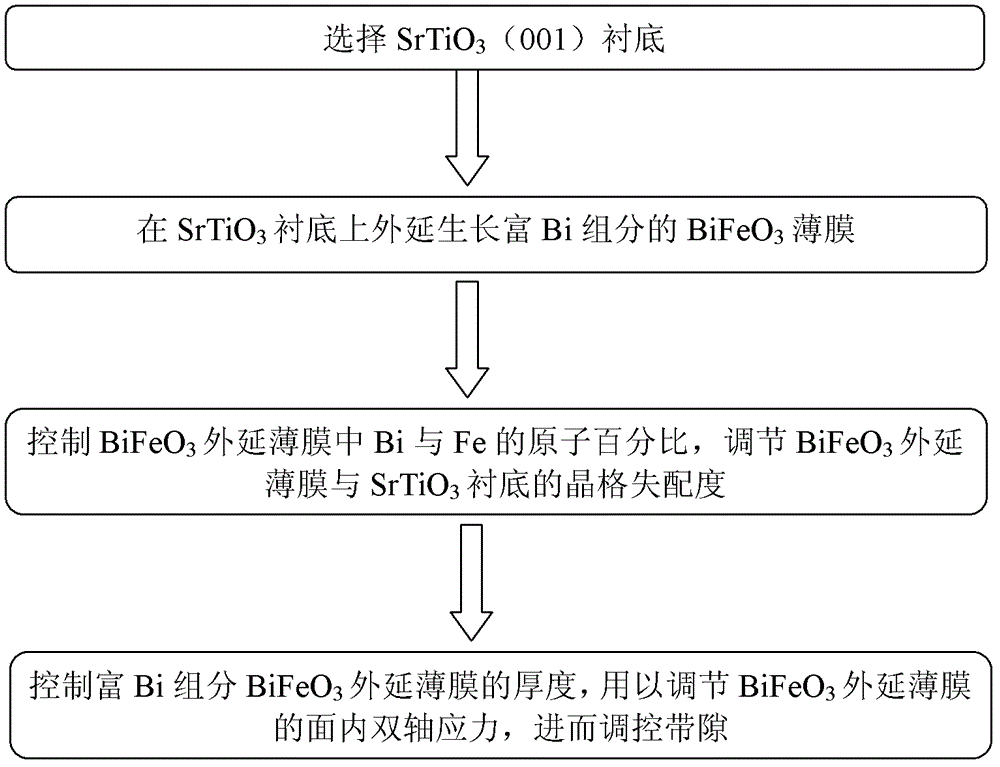

[0017] see figure 1 As shown, the present invention provides a SrTiO 3 Controlled multiferroic BiFeO on substrate 3 The method for epitaxial film bandgap, comprises the steps:

[0018] 1) Choose a SrTiO 3 substrate. The chosen substrate is (001) oriented. First, the SrTiO 3 The substrate needs to be pre-annealed first, and the pre-annealing temperature is set at 850-1000°C. The pre-annealing is carried out under a flowing oxygen atmosphere at an atmospheric pressure, and the pre-annealing time is set at 1-3 hours. SrTiO 3 The substrate needs to undergo surface corrosion treatment. The corrosion solution is a buffer solution of hydrofluoric acid and ammonium fluoride. The pH of the buffer solution is set at 3.5-5.5, and the corrosion time is 20-60 seconds; SrTiO 3 The substrate needs post-annealing treatment, the post-annealing temperature is set at 850-1000°C, the post-annealing is carried out under a flowing oxygen atmosphere at an atmospheric pressure, and the post-a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com