Dielectric ceramic material with high-temperature stability and preparation method thereof

A technology of dielectric ceramics and stability, which is applied in the field of dielectric ceramic materials with high temperature stability and its preparation. It can solve the problems that temperature stability cannot meet the requirements of multilayer ceramic capacitors, and achieve good market prospects and low prices. , the effect of excellent dielectric temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The dielectric ceramic material with high temperature stability of the present invention is prepared as follows:

[0033] (1) The selected raw materials have a main content greater than 98.5%.

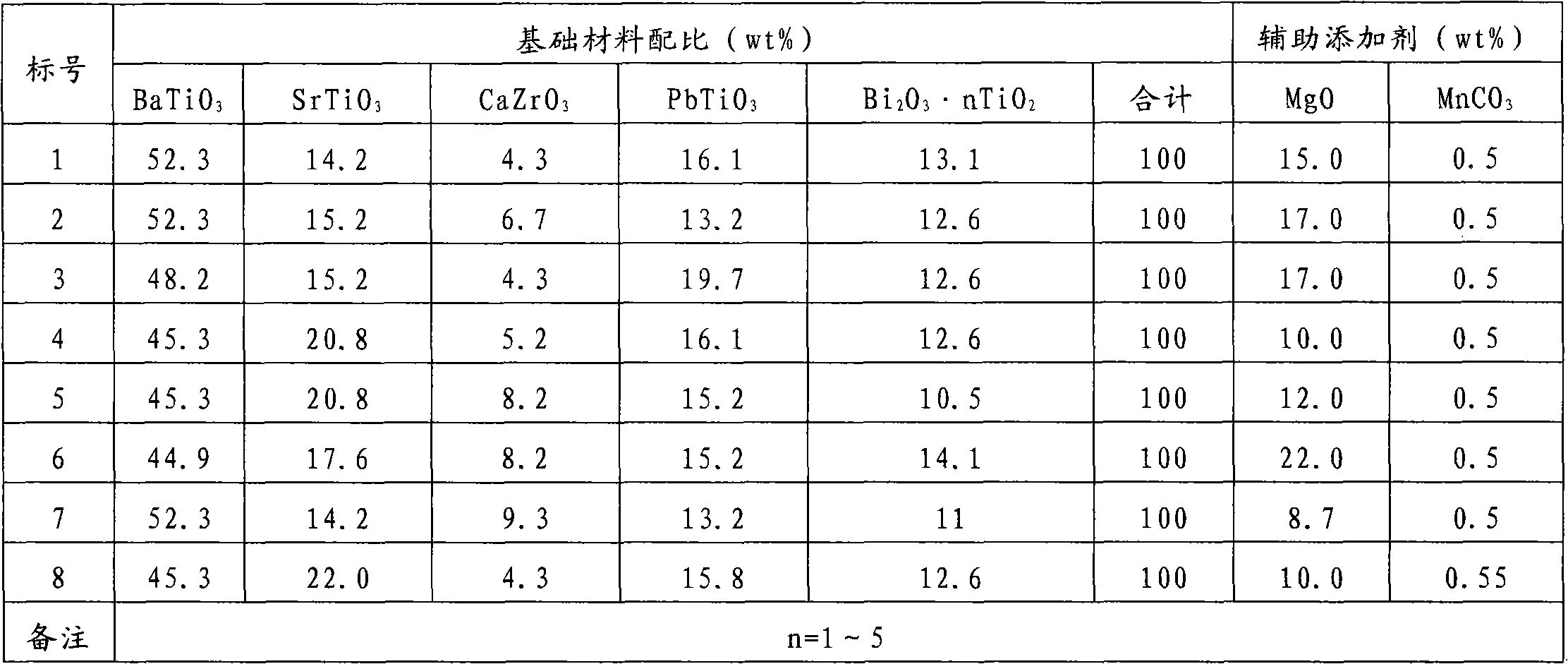

[0034] (2) Calculate the basic material formula according to the following molar ratio:

[0035] BaCO 3 :TiO 2 = 1:1, for the preparation of BaTiO 3 ;

[0036] SrCO 3 :TiO 2 = 1:1, for the preparation of SrTiO 3 ;

[0037] PbO:TiO 2 = 1:1, for the preparation of PbTiO 3 ;

[0038] Bi 2 o 3 : nTiO 2 = 1:n, for the preparation of Bi 2 o 3 · nTiO 2 (n=1~5);

[0039] CaCO 3 : ZrO 2 = 1:1, for the preparation of CaZrO 3 ;

[0040] (3) The raw materials of the basic materials calculated and weighed in step (2) will be processed according to the following process requirements:

[0041] (A) Wet ball milling: ball milling time = 12 hours.

[0042] (B) discharging and dehydration by pressure filtration.

[0043] (C) Drying: keep at 120°C for 12 hours.

[0044] (D) B...

Embodiment 2

[0073] The dielectric ceramic material with high temperature stability of the present invention is prepared as follows:

[0074] (1) The selected raw materials have a main content greater than 98.5%.

[0075] (2) Calculate the basic material formula according to the following molar ratio:

[0076] BaCO 3 :TiO 2 = 1:1, for the preparation of BaTiO 3 ;

[0077] SrCO 3 :TiO 2 = 1:1, for the preparation of SrTiO 3 ;

[0078] PbO:TiO 2 = 1:1, for the preparation of PbTiO 3 ;

[0079] Bi 2 o 3 : nTiO 2 = 1:n, for the preparation of Bi 2 o 3 · nTiO 2 (n=1~5);

[0080] CaCO 3 : ZrO 2 = 1:1, for the preparation of CaZrO 3 ;

[0081] (3) The raw materials of the basic materials calculated and weighed in step (2) will be processed according to the following process requirements:

[0082] (A) Wet ball milling: ball milling time = 12 hours.

[0083] (B) discharging and dehydration by pressure filtration.

[0084] (C) Drying: keep at 120°C for 12 hours.

[0085] (D)...

Embodiment 3

[0113] The dielectric ceramic material with high temperature stability of the present invention is prepared as follows:

[0114] (1) The selected raw materials have a main content greater than 98.5%.

[0115] (2) Calculate the basic material formula according to the following molar ratio:

[0116] BaCO 3 :TiO 2 = 1:1, for the preparation of BaTiO 3 ;

[0117] SrCO 3 : TiO 2 = 1:1, for the preparation of SrTiO 3 ;

[0118] PbO:TiO 2 = 1:1, for the preparation of PbTiO 3 ;

[0119] Bi 2 o 3 : nTiO 2 = 1:n, for the preparation of Bi 2 o 3 · nTiO 2 (n=1~5);

[0120] CaCO 3 : ZrO 2 = 1:1, for the preparation of CaZrO 3 ;

[0121] (3) The raw materials of the basic materials calculated and weighed in step (2) will be processed according to the following process requirements:

[0122] (A) Wet ball milling: ball milling time = 12 hours.

[0123] (B) discharging and dehydration by pressure filtration.

[0124] (C) Drying: keep at 120°C for 12 hours.

[0125] (D) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com