Anti-oxidation decarburized coating in process of billet rolling and preparation method thereof

A rolling process and anti-oxidation technology, applied in the field of anti-oxidation and decarbonization coatings and their preparation, can solve the problems of human health hazards, occupation of large sites, pollution of the surrounding environment, etc., to solve pollution problems, reduce oxidation rate and carbon loss , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] According to the weight ratio in Table 1, three kinds of anti-oxidation and decarburization coatings were prepared respectively. The vanadium-extracted tailings were roasted at 1200 °C for 3 hours. , and made into a viscous suspension fluid, the anti-oxidation and decarburization coating product can be obtained. The chemical composition of the vanadium extraction tailings used is: TiO 2 11.0%, Al 2 o 3 3.2%, SiO 2 14.4%, MnO 2 7.2%, Fe 2 o 3 45.2%, V 2 o 5 1.5%, Cr 2 o 3 1.9%, and the rest are unavoidable impurities.

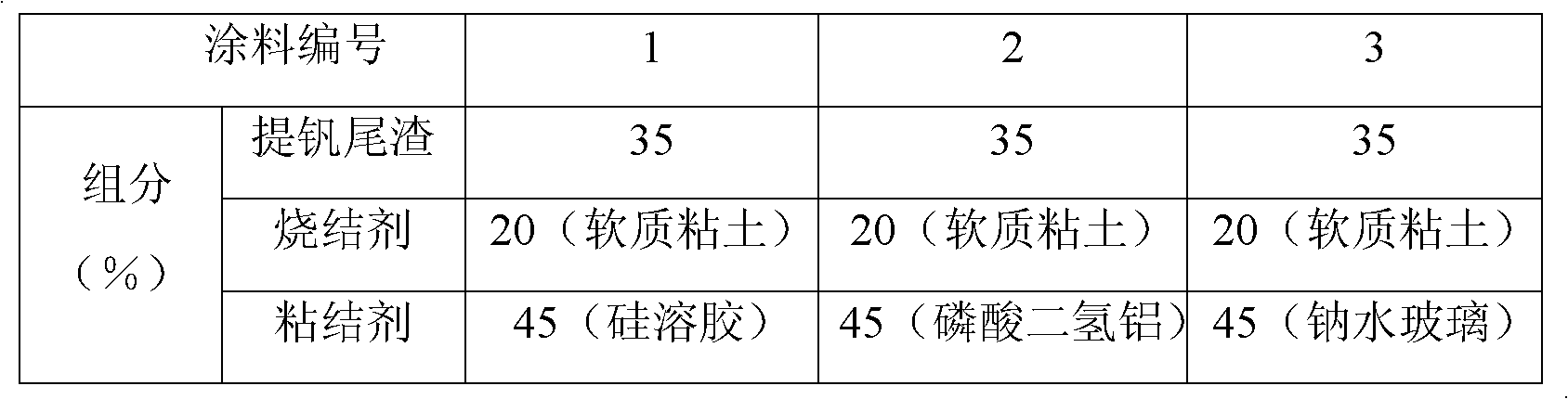

[0021] Table 1 Anti-oxidation decarburization coating raw material weight ratio

[0022]

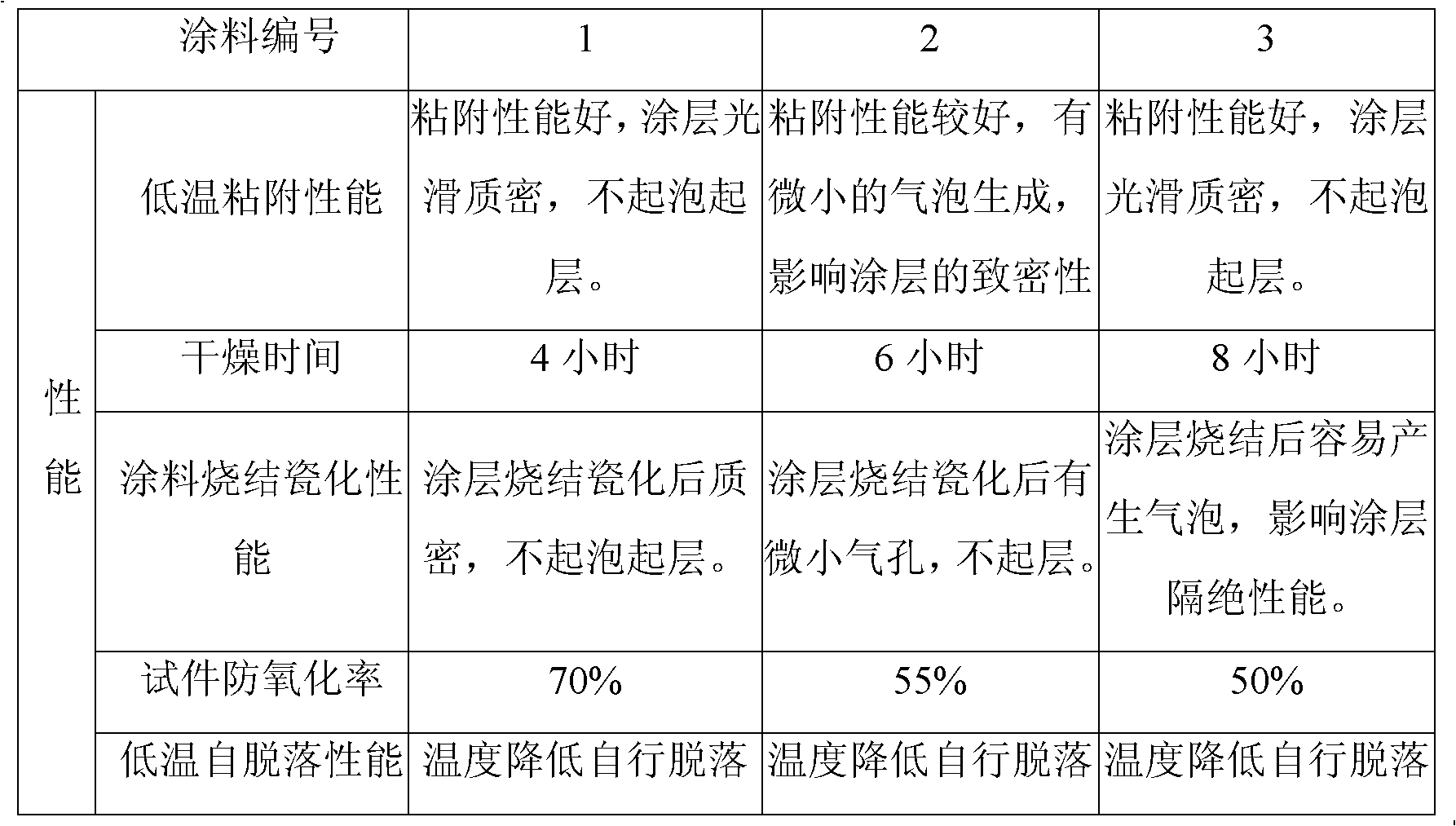

[0023] Brush the billet anti-oxidation and decarburization paint prepared above on the surface of the heavy rail steel test piece (the heavy rail steel test piece must be cleaned and degreased before painting, and then the pretreatment liquid is applied to increase the adhesion of the paint and the steel billet force, the pretreatment liquid is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com