High-temperature-resistance infrared-radiation-attenuation-resistance energy-saving coating

An energy-saving coating and infrared radiation technology, which is applied in the direction of fire-proof coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of low energy-saving effect, narrow applicable temperature range, and reduced crystal activity, so as to prevent infrared radiation attenuation, Reduces maintenance workload and suppresses growth of crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

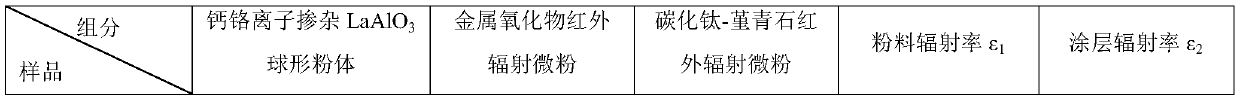

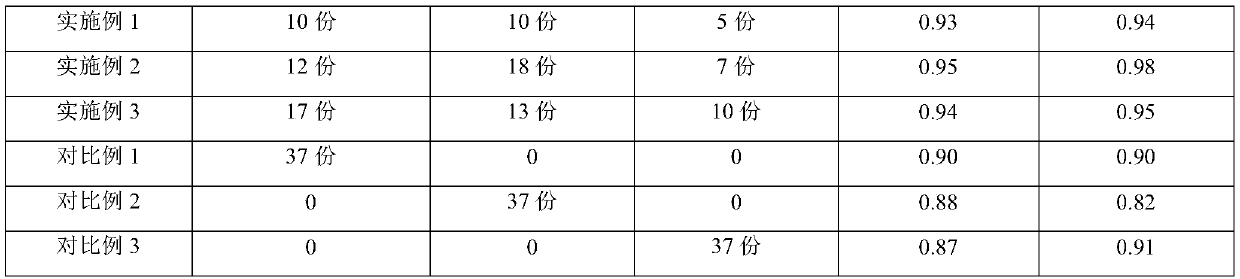

Embodiment 1

[0032] A high temperature resistant and infrared radiation attenuation energy-saving paint, which is composed of the following components by weight: calcium chromium ion doped LaAlO 3 10 parts of spherical powder, 10 parts of metal oxide infrared radiation powder, 5 parts of titanium carbide-cordierite infrared radiation powder, 15 parts of filler, 0.1 part of retarder, 30 parts of binder, 10 parts of solvent, 0.15 part of dispersant, 0.15 parts of coupling agent and 0.05 parts of defoamer.

[0033] Further, the calcium chromium ion doped LaAlO 3 The preparation method of spherical powder is: submicron raw material La 2 O 3 , CaO, Cr 2 O 3 , AlO 3 Follow La 1-x Ca x Cr y Al 1-y O 3 (x = 0.1; y = 0.15) The stoichiometric ratio is mixed, and polyvinyl alcohol, PAA-NH4, n-butanol are added, and an appropriate amount of water is added. The raw material: water = 1:1 ratio is ball milled for 2 hours, and sprayed The spherical powder is prepared by the granulator, dried in an oven at 80℃...

Embodiment 2

[0052] A high temperature resistant and infrared radiation attenuation energy-saving paint, which is composed of the following components by weight: calcium chromium ion doped LaAlO 3 12 parts of spherical powder, 18 parts of metal oxide infrared radiation powder, 7 parts of titanium carbide-cordierite infrared radiation powder, 20 parts of filler, 0.15 parts of retarder, 40 parts of binder, 15 parts of solvent, 0.20 part of dispersant, 0.25 part of coupling agent and 0.1 part of defoamer.

[0053] Further, the calcium chromium ion doped LaAlO 3 The preparation method of spherical powder is: submicron raw material La 2 O 3 , CaO, Cr 2 O 3 , AlO 3 Follow La 1-x Ca x Cr y Al 1-y O 3 (x = 0.1; y = 0.3) Mix with stoichiometric ratio, add polyvinyl alcohol, PAA-NH4, n-butanol, then add an appropriate amount of water, ball mill for 2 hours with a ratio of raw material: water = 1:1, and use spray The spherical powder is prepared by the granulator, dried in an oven at 80℃, and then sent t...

Embodiment 3

[0072] A high temperature resistant and infrared radiation attenuation energy-saving paint, which is composed of the following components by weight: calcium chromium ion doped LaAlO 3 17 parts of spherical powder, 13 parts of metal oxide infrared radiation powder, 10 parts of titanium carbide-cordierite infrared radiation powder, 25 parts of filler, 0.2 part of retarder, 50 parts of binder, 20 parts of solvent, 0.25 part of dispersant, 0.35 parts of coupling agent and 0.15 parts of defoamer.

[0073] Further, the calcium chromium ion doped LaAlO 3 The preparation method of spherical powder is: submicron raw material La 2 O 3 , CaO, Cr 2 O 3 , AlO 3 Follow La 1-x Ca x Cr y Al 1-y O 3 (x=0.2; y=0.5) Mix in stoichiometric ratio, add polyvinyl alcohol, PAA-NH4, n-butanol, then add an appropriate amount of water, ball mill for 2 hours with a ratio of raw material: water = 1:1, and use spray The spherical powder is prepared by the granulator, dried in an oven at 80℃, and then sent to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com