Water-based vacuum ceramic microbead insulation paint used for textile fabric substrates and preparation method thereof

A technology of vacuum ceramics and heat-insulating coatings, applied in textiles and papermaking, etc., can solve the problems of limited reflection radiation function, no specific expression of heat insulation effect, limited heat insulation function, etc., achieve excellent heat insulation effect, meet durability Folding and anti-scratch requirements, the effect of low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

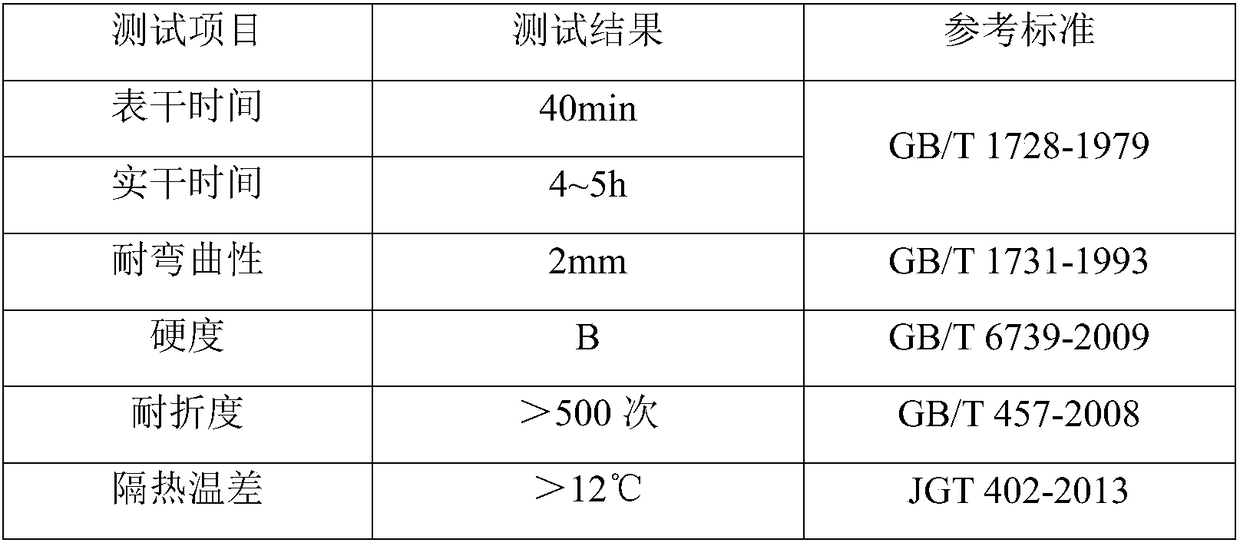

Examples

Embodiment 1

[0026] 1. Experimental materials: several pieces of woven cloth, the size is 70*50mm.

[0027] 2. Coating Preparation

[0028] Take part of the vacuum ceramic microbeads and infiltrate them with self-made organic-inorganic hybrid resin, then dry them for later use; take 0.25g dispersant,

[0029] Add 1g of film-forming aid to 60g of resin, stir at low speed for 10min, add dried 5g of titanium dioxide, 2g of mica powder, and shear at high speed for 30-40min to obtain color paste for later use; weigh 30g of organic-inorganic hybrid resin surface-treated Add vacuum ceramic beads to the color paste, stir at low speed and add slowly, then add 0.1g bactericide, 0.25g dispersant, 1g film-forming aid, 0.25g leveling agent, 0.5g antifreeze and mix at low speed for 10-15min Evenly, finally add an appropriate amount of deionized water to adjust the viscosity to obtain a water-based vacuum ceramic microbead thermal insulation coating, and brush it on the prepared textile cloth substrate....

Embodiment 2

[0031] 1. Experimental material: with embodiment 1.

[0032] 2. Coating Preparation

[0033] Take part of the vacuum ceramic microbeads and infiltrate them with self-made organic-inorganic hybrid resin, and then dry them for later use; take 0.25g of dispersant and 1g of film-forming aids and add them to 15g of resin, stir at low speed for 10min, add dried 3g of titanium dioxide, 2g of mica powder, high-speed shearing for 30-40min to obtain the color paste for later use; weigh 0.1g of bactericide, 0.25g of dispersant, and 1g of film-forming aid to add to 45g of resin, stir at low speed for 10min, weigh 30g of vacuum ceramic microbeads slowly Add to the above system, add while stirring at a low speed, add the remaining additives after the addition is complete, then stir at a low speed for 15 minutes to mix evenly to obtain a microbead slurry; slowly add the obtained color paste to the microbead slurry, and stir at a low speed for 10 to 15 minutes Mix evenly, and finally add an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com