High-intensity texture copper-nickel/nickel-tungsten alloy double-layered composite base band and preparation method thereof

A nickel-tungsten alloy, double-layer composite technology, applied in the direction of metal layered products, chemical instruments and methods, layered products, etc., can solve the problem that the mechanical strength and magnetic properties cannot meet the requirements of high-performance coated conductor strips, and it is difficult to obtain Strong cubic texture, nickel-tungsten alloy stacking fault energy reduction and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

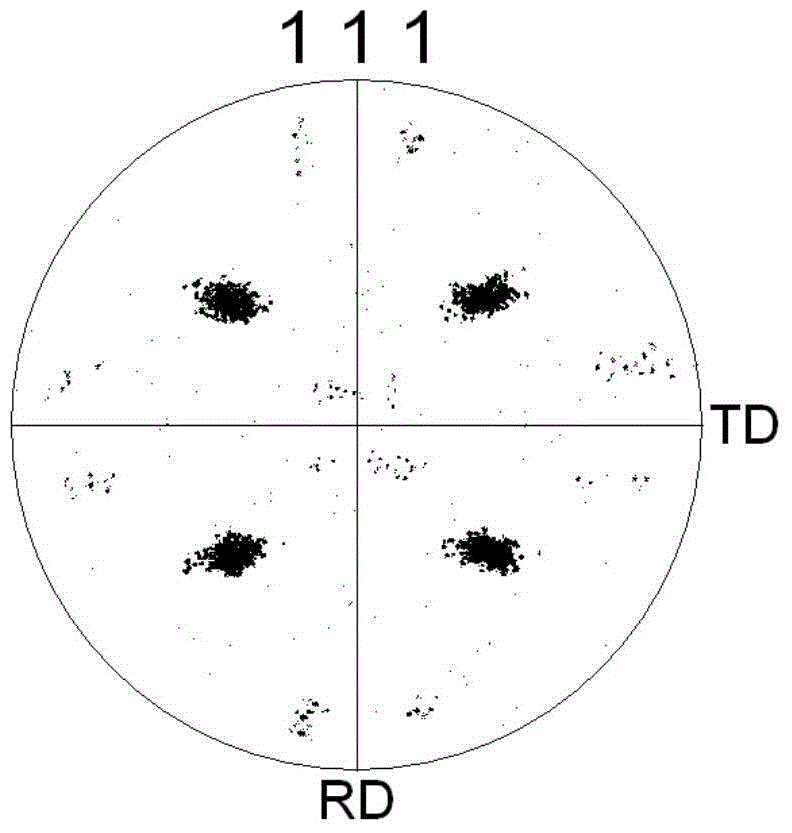

[0016] The copper-nickel alloy with a copper atomic percentage of 46% obtained by smelting is forged at high temperature and hot-rolled, and then wire-cut into a billet with a thickness of 5mm, and the surface of the billet is polished, which is defined as A; The nickel-tungsten mixed powder with a content of 12% is defined as B, A and B are put into the mold layer by layer, the thickness of B is 7mm, and the copper-nickel / nickel-tungsten double-layer composite ingot is obtained by spark plasma sintering. The composite billet obtained above is cold-rolled to a strip with a thickness of 40 μm, and then the cold-rolled composite base strip is subjected to recrystallization heat treatment. The recrystallization heat treatment process is: heat preservation at 1250 ° C for 20 minutes, and finally obtain high-strength, non-ferromagnetic Copper-nickel / nickel-tungsten composite substrate with strong cubic texture. The (111) surface pole figure of the alloy substrate surface is as foll...

Embodiment 2

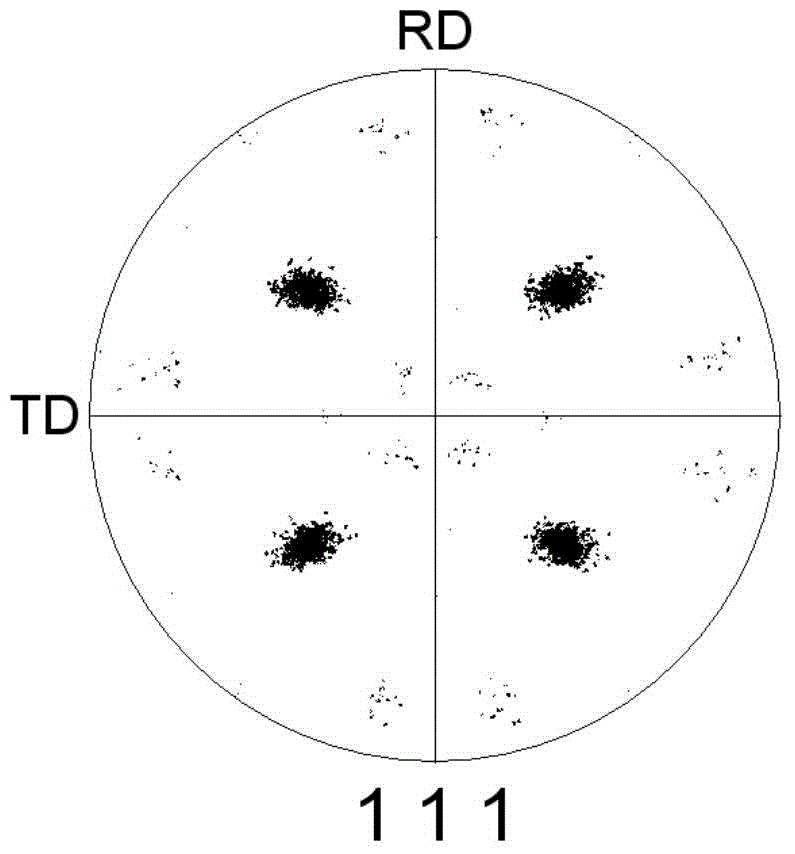

[0018] The copper-nickel alloy obtained by smelting with a copper atomic percentage of 46% is forged at high temperature and hot-rolled, and then wire-cut into a billet with a thickness of 5mm, and the surface of the billet is polished, which is defined as A; The nickel-tungsten mixed powder with a content of 12% is defined as B, A and B are put into the mold layer by layer, the thickness of B is 10mm, and the copper-nickel / nickel-tungsten double-layer composite ingot is obtained by spark plasma sintering. The composite ingot obtained above is cold-rolled to a strip with a thickness of 40 μm, and then the cold-rolled composite base strip is subjected to recrystallization heat treatment. The recrystallization heat treatment process is: heat preservation at 1300 ° C for 20 minutes, and finally obtain high-strength, non-ferromagnetic Copper-nickel / nickel-tungsten composite substrate with strong cubic texture. The (111) surface pole figure of the alloy substrate surface is as foll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com