Preparation method of a ferromagnetic textured nickel-tungsten/nickel-vanadium/nickel-tungsten composite substrate

A composite baseband and ferromagnetic technology, applied in the field of preparation of non-ferromagnetic textured nickel-tungsten/nickel-vanadium/nickel-tungsten composite basebands, can solve problems such as poor oxidation resistance, achieve high mechanical strength and avoid oxidation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

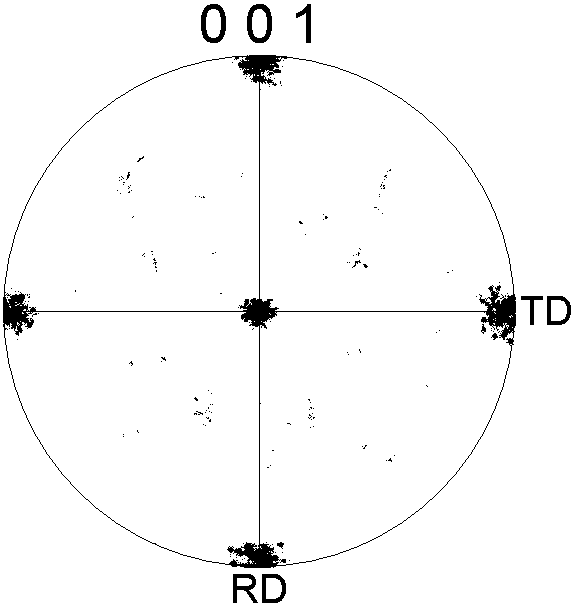

[0019] After grinding the oxide skin on the surface of nickel-tungsten alloy with 9.5 atomic percent of tungsten obtained from smelting, it is used as the outer layer material of the composite ingot; the nickel-vanadium mixed with 10 atomic percent of vanadium obtained by ball milling Powder, as the core material of the composite billet; the nickel-tungsten alloy and nickel-vanadium mixed powder are placed in the mold in the order of nickel-tungsten-nickel-vanadium-nickel-tungsten, with a thickness ratio of 1:1:1, and spark plasma sintering is used technology to obtain nickel-tungsten / nickel-vanadium / nickel-tungsten composite ingot, in which the discharge plasma sintering process is: heat preservation at 680°C for 5 minutes, sintering pressure is 30MPa; the sintered nickel-tungsten / nickel-vanadium / nickel-tungsten composite ingot Deformation cold rolling, the pass deformation is 10%, and the total deformation is 99.5%-99.9%. Finally, the nickel-tungsten / nickel-vanadium / nickel-tu...

Embodiment 2

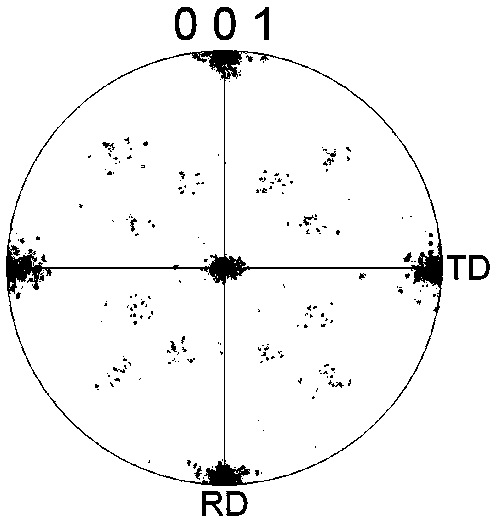

[0021] After grinding the oxide skin on the surface of nickel-tungsten alloy with 10 atomic percent of tungsten obtained from smelting, it is used as the outer layer material of the composite ingot; the mixed nickel-vanadium with 10 atomic percent of vanadium obtained by ball milling Powder, as the core material of the composite billet; the nickel-tungsten alloy and nickel-vanadium mixed powder are placed in the mold in the order of nickel-tungsten-nickel-vanadium-nickel-tungsten, with a thickness ratio of 1:1:1, and spark plasma sintering is used Nickel-tungsten / nickel-vanadium / nickel-tungsten composite billets were obtained through technology, and the discharge plasma sintering process was: holding at 700°C for 5 minutes, and the sintering pressure was 35MPa; The deformation is cold rolled, the deformation of each pass is 12%, and the total deformation is 99.5%-99.9%. Finally, the nickel-tungsten / nickel-vanadium / nickel-tungsten composite base belt is obtained by recrystalliza...

Embodiment 3

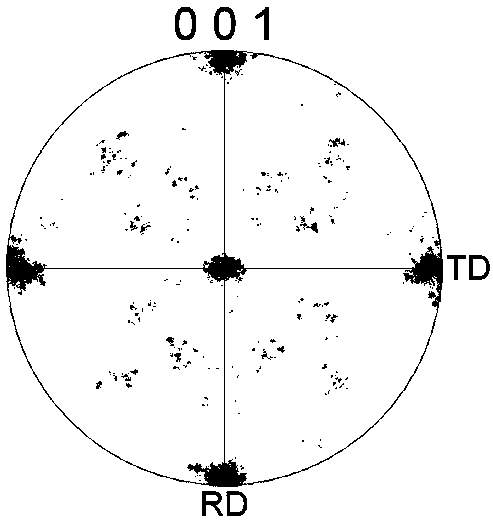

[0023] After grinding the oxide skin on the surface of the nickel-tungsten alloy with 11 atomic percent of tungsten obtained from smelting, it is used as the outer layer material of the composite billet; the nickel-vanadium mixed with 10 atomic percent of vanadium obtained by ball milling Powder, as the core material of the composite billet; the nickel-tungsten alloy and nickel-vanadium mixed powder are placed in the mold in the order of nickel-tungsten-nickel-vanadium-nickel-tungsten, with a thickness ratio of 1:1:1, and spark plasma sintering is used technology to obtain nickel-tungsten / nickel-vanadium / nickel-tungsten composite ingot, in which the discharge plasma sintering process is: hold at 720°C for 5 minutes, and the sintering pressure is 40MPa; the nickel-tungsten / nickel-vanadium / nickel-tungsten composite ingot Deformation cold rolling, the pass deformation is 15%, and the total deformation is 99.5%-99.9%. Finally, the nickel-tungsten / nickel-vanadium / nickel-tungsten com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com