A preparation method of copper-based/nickel-based composite long base tape for coated conductors

A coated conductor, copper-based technology, applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of not being suitable for use in the field of 100-meter-long tape preparation, billet size limitation, high cost, etc., to achieve good mechanical Performance, low cost, no effect on ferromagnetic mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

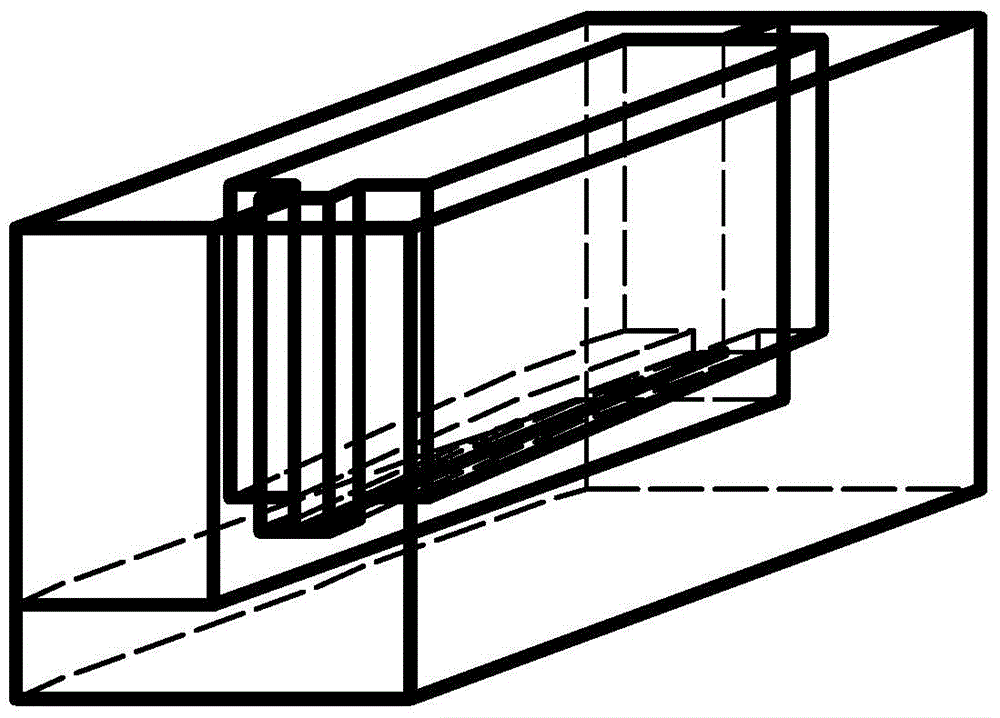

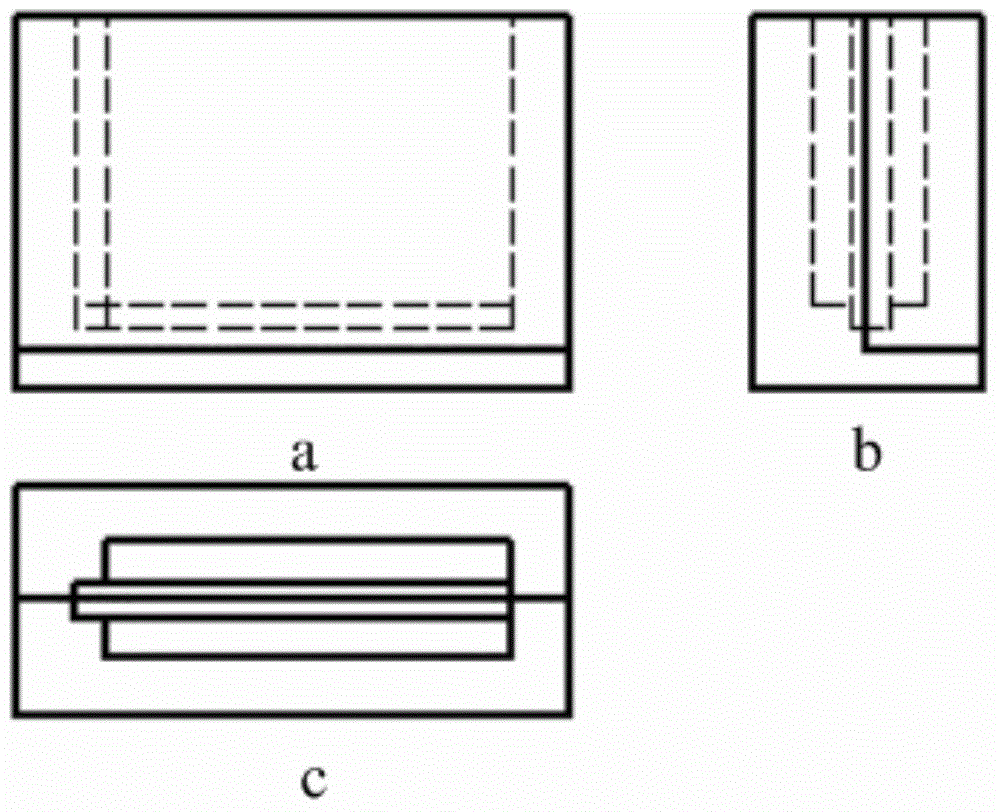

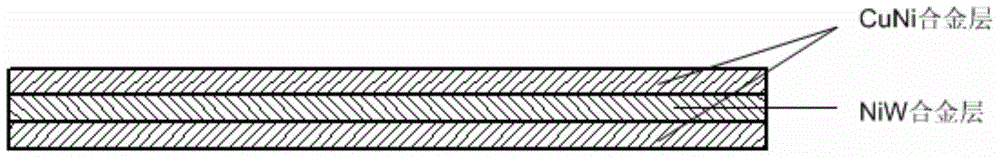

[0018] The NiW alloy billet was obtained by smelting, and then after high-temperature hot forging and descaling, it was cut to obtain an alloy block with a thickness of 3 cm, a width of 8 cm, and a length of 15 cm. After the NiW alloy block is inserted into the mold, the CuNi alloy layer is cast in the mold under vacuum protection, and the original elongated composite ingot with a thickness of 9 cm, a width of 5 cm and a length of 20 cm is obtained after surface treatment. After the 900°homogenization heat treatment, the long composite ingot is hot-rolled with a large deformation of 15% in each pass, the total deformation is 50%, and the hot-rolling temperature is 800°C. Finally, cold rolling, edge trimming and high-temperature annealing treatment are performed to obtain a 100-meter composite long base belt with a thickness of 0.08 mm and a texture content of more than 98%.

example 2

[0020] The NiW alloy ingot was obtained by smelting, and then after high-temperature hot forging and descaling, it was cut to obtain an alloy block with a thickness of 5 cm, a width of 10 cm, and a length of 30 cm. After the NiW alloy block was inserted into the mold, the CuNi alloy layer was cast in the mold under vacuum protection, and the original elongated composite ingot with a thickness of 15 cm, a width of 7 cm and a length of 27 cm was obtained after surface treatment. After the 900°homogenization heat treatment, the long composite ingot is hot-rolled with a large deformation of 30% in each pass, the total deformation is 80%, and the hot-rolling temperature is 1000°C. Finally, cold rolling, trimming and high-temperature annealing are performed to obtain a 200-meter-level composite long base belt with a thickness of 0.08 mm and a texture content of more than 98%.

example 3

[0022] The NiW alloy ingot was obtained by smelting, and then after high-temperature hot forging and descaling, it was cut to obtain an alloy block with a thickness of 3 cm, a width of 8 cm, and a length of 28 cm. After the NiW alloy block is inserted into the mold, the CuNi alloy layer is cast in the mold under vacuum protection, and the original elongated composite ingot with a thickness of 9 cm, a width of 5 cm and a length of 25 cm is obtained after surface treatment. After the 900°homogenization heat treatment, the long composite ingot is hot-rolled with a large deformation of 30% in each pass, the total deformation is 80%, and the hot-rolling temperature is 1000°C. Finally, cold rolling, edge trimming and high-temperature annealing treatment are performed to obtain a 100-meter composite long base belt with a thickness of 0.08 mm and a texture content of more than 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com