Vanadium-doped crystalline tungsten trioxide electrochromic film and preparation method thereof

A tungsten trioxide and electrochromic technology, applied in the direction of coating, can solve the problem of thin film particles and other problems, and achieve the effects of low cost, simple preparation process and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

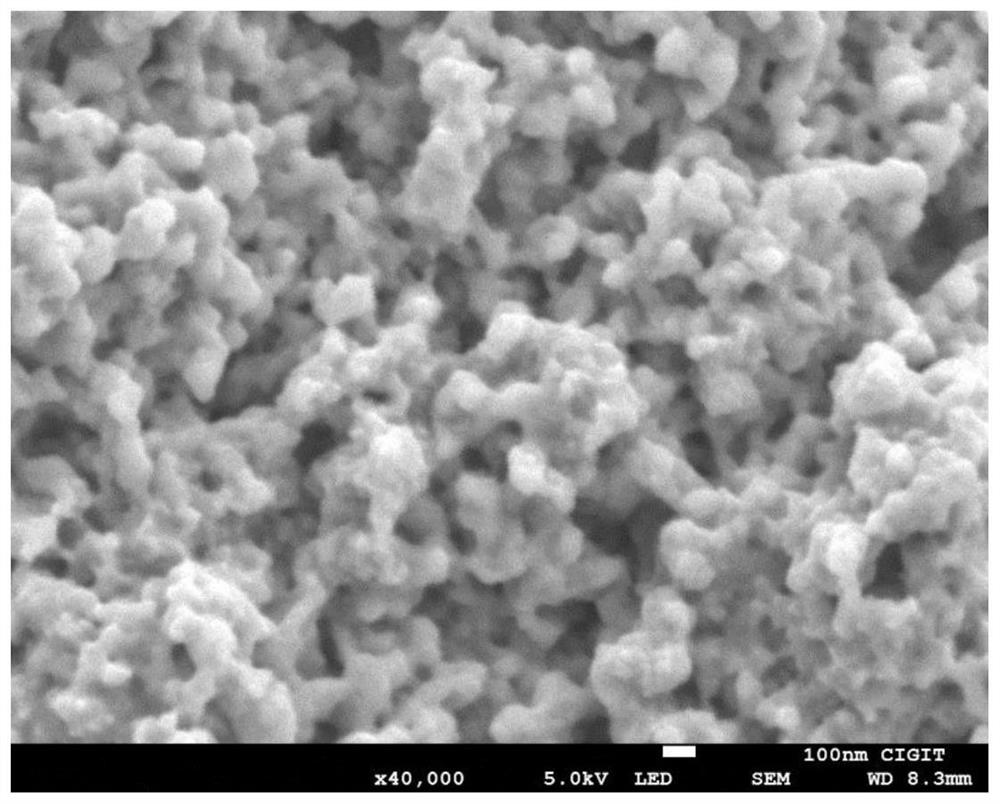

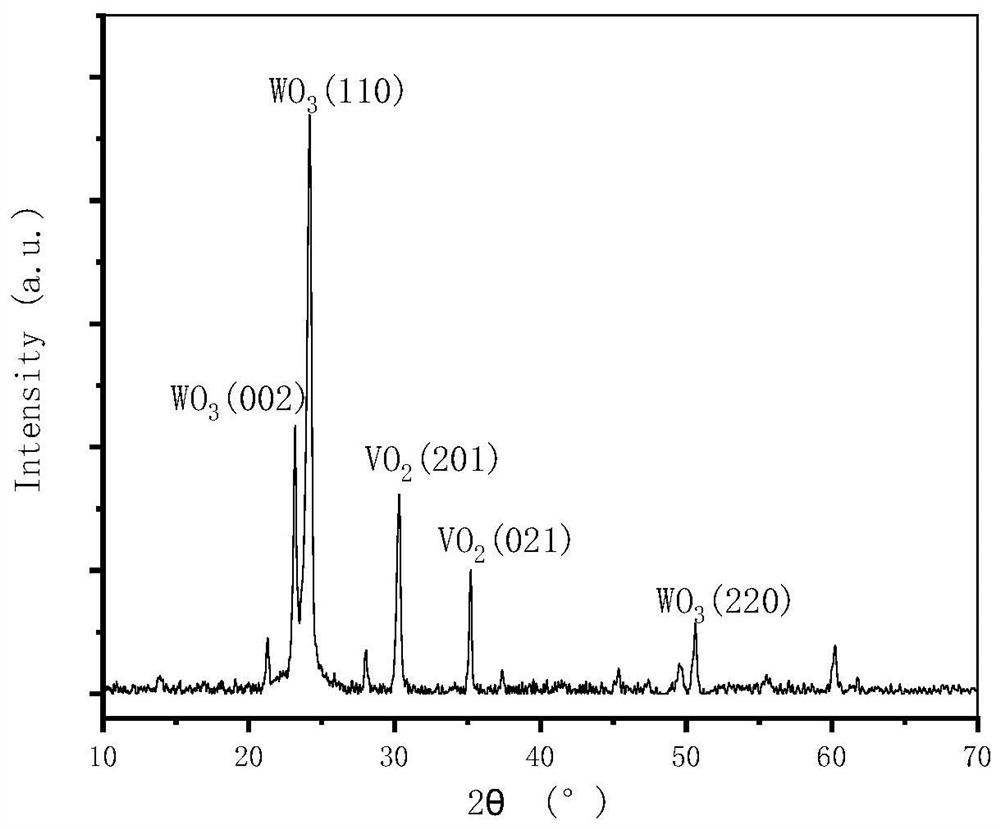

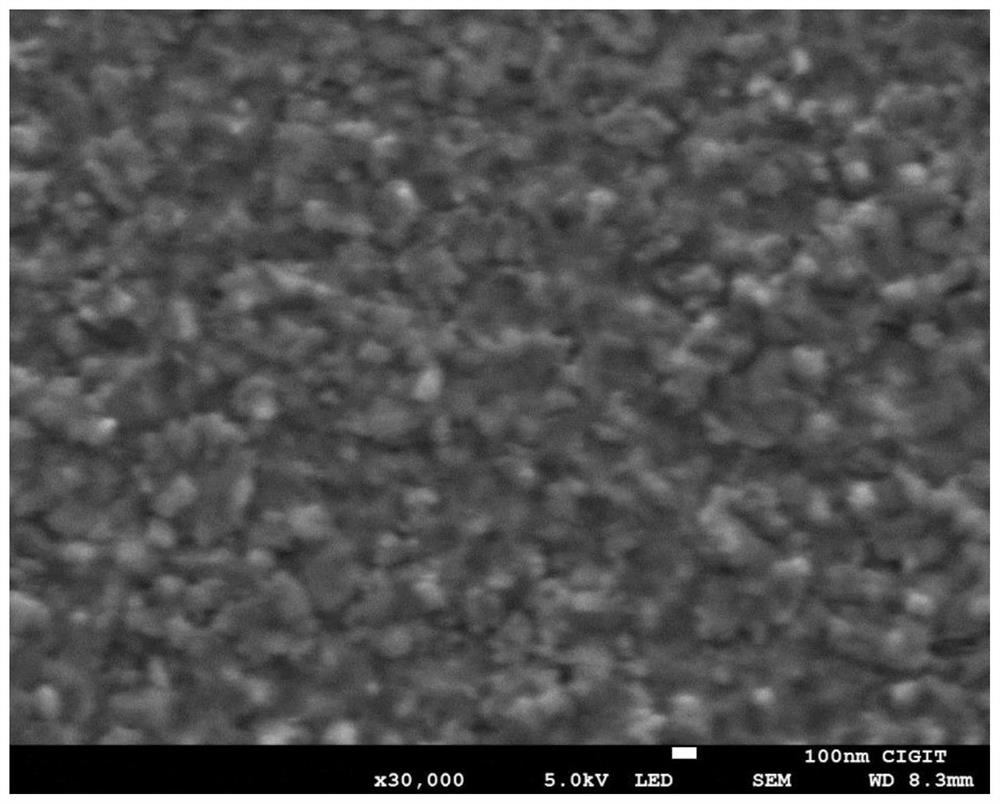

Image

Examples

preparation example Construction

[0029] The preparation method specifically includes the following steps: dissolving tungsten source and vanadium source in quantitative deionized water to obtain a mixed solution; adding hydrogen peroxide (H2O2) and strong acid, adjusting the pH value of the mixed solution to 1-1.6 and stirring evenly to obtain an electrochemical Deposition solution; place the transparent conductive substrate as the working electrode in the obtained electrochemical deposition solution and apply a negative potential, adopt a three-electrode electrodeposition system, and deposit vanadium-doped crystalline tungsten trioxide electrochromic film by pulse electrodeposition method .

[0030] In the embodiment of the present invention, after dissolving the tungsten source and the vanadium source in deionized water, a mixed solution is obtained. Then add strong acid and hydrogen peroxide to the mixed solution to adjust the pH value of the mixed solution to between 1 and 1.6 and stir it with a magnetic ...

Embodiment 1

[0033] 1. Clean the conductive glass substrate: Clean the ITO conductive glass substrate with an area of 1cm×4cm (square resistance 6-7Ω) with acetone, absolute ethanol, and deionized water for 10 minutes, and then dry it at 60°C. A clean conductive glass substrate is obtained.

[0034] 2. Configure the electrodeposition solution:

[0035] ①Weigh 1.4g of sodium tungstate dihydrate (analytical grade) and 0.01g of sodium metavanadate, and put them into a beaker.

[0036] ② Measure 60ml of deionized water into the beaker and stir with a glass. Measure 0.3ml of hydrogen peroxide solution (30% mass fraction) and add it to the container filled with sodium tungstate dihydrate and sodium metavanadate.

[0037] ③Add a certain amount of 2mol / L sulfuric acid aqueous solution, adjust the mixed solution to ph=1.4, and magnetically stir the mixed solution for 20 minutes at a speed of 1200 rpm to prepare an electrochemical deposition solution.

[0038] 3. Thin film deposited by electroc...

Embodiment 2

[0043] 1. Clean the conductive glass substrate: Clean the ITO conductive glass substrate with an area of 1cm×4cm (square resistance 6-7Ω) with acetone, absolute ethanol, and deionized water for 10 minutes, and then dry it at 60°C. A clean conductive glass substrate is obtained.

[0044] 2. Configure the electrodeposition solution:

[0045] ①Weigh 1.4g of sodium tungstate dihydrate (analytical grade) and 0.02g of sodium metavanadate, and put them into a beaker.

[0046] ② Measure 60ml of deionized water into the beaker and stir with a glass. Measure 0.1ml of hydrogen peroxide solution (30% mass fraction) and add it to the container containing sodium tungstate dihydrate and sodium metavanadate.

[0047] ③Add a certain amount of 2mol / L sulfuric acid aqueous solution to adjust the mixed solution to ph=1.4, and magnetically stir the mixed solution for 20 minutes at a speed of 1200 rpm to prepare an electrochemical deposition solution.

[0048] 3. Electrochemical deposition of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com